What is the PIW of the Belt and How Can It be Converted into EP Belt?

General Introduction:

We often see 220PIW/2, 330PIW/3 or 440PIW/4 in the specification of conveyor belt, so what does “PIW” mean and how is it coverted into EP grade in conveyor belt? “PIW” is an imperial measurement unit, means “Pounds Per Inch of Belt Width” in American standard(RMA), described as “Max.Oper.Working Strength” EP conveyor belt, and PIW standard is widely used in North and South American countries including the United States.

Outside the USA, the “Breaking Strength” of the EP conveyor belt is rated in N/mm, i.e. Newton per millimeter of EP rubber conveyor belt width. The belt breaking strength is determined precisely, depending on the operating conditions, the splice type, etc. The safety factor is related to the weakest point of the EP conveyor belt, which is the splice section of the belt. The biggest difference between PIW and N/mm is that PIW describes the “Operation Tension“, while N/mm describes the “Strength at Breaking“.

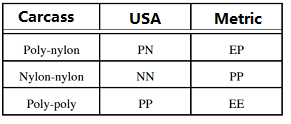

Let’s check out the yarn difference between USA and Metric.

So why do we calculate PIW?

This is because the strength of a conveyor belt, whether it’s the carcass tension rating or ultimate breaking strength, represents the amount of force that can be applied to the belt. For example, a 3 ply conveyor belt is rated at 110 PIW per layer, which equates to 330 PIW conveyor belt. This is the maximum rated tension that the belt can operate without damage, exceeding the belt’s rated tension may cause breakage, overstretching, joint failure, etc., so it is important to calculate the PIW value in advance..

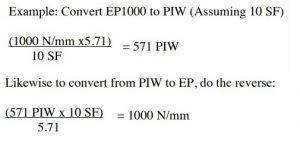

How PIW and N/mm convert to each other?

Without consideration of a safety factor, PIW is converted into N/mm(EP) by multiplying by 0.175.

Example: 2284 PIW x 0.175 = 400 N/mm(400kN/m)

N/mm converted into PIW are multiplied by 5.71. Example: 400 N/mm x 5.71 = 2284 PIW

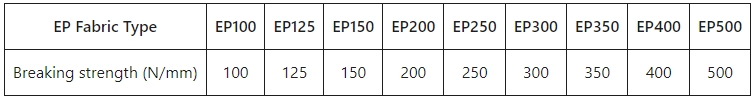

How to convert PIW conveyor belt to EP conveyor belt

Let us take the most common PIW330/3 conveyor belt as an example: 330PIWx 0.175=57.75. If the safety factory was 10, then the overall strength of the conveyor belt will be 577.5N/mm, and divided this value by 3 EP layers, then each layer of EP fabric strength is 192.5N/mm. According to the above EP model table as below, EP200 is closest to this value, so the EP model closest to PIW330/3 is EP200, 3-layer conveyor belt, which is EP600/3 conveyor belt.

(The above conversion is applicable to various conveyor belts types, such as heat-resistant conveyor belts, fire-resistant conveyor belts, chevron conveyor belts and pipe conveyor belts etc.)

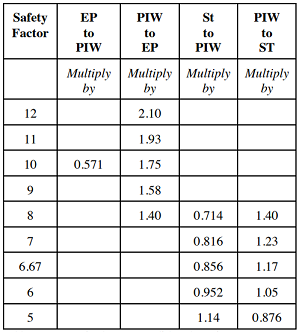

Conversation between USA and Metric under different safety factor:

What is the Safety Factor of Conveyor Belt?

How to Calculate PIW Value of Conveyor Belt?

How to Convert PIW belt into EP Belt?

Practical Converting Example:

Conveyor belt with tensile strength of belt 630N/mm(630kN/m),3ply, described as EP630/3, converted to PIW would be 630 X 0.5716 = 360 PIW (10:1 safety factor). So EP630/3 in US terms would be (3 plies 360 PIW). EP630/3 is actually refers to 3 plies EP200 fabric and EP1000/3 refers to 3 plies of EP315 fabric. EP800/4 refer to 4 plies EP200 fabric so on…. You may also convert EP200 X 0.5716 = 114 PIW per ply, EP315 X 0.5716 = 180 PIW per ply and so on.

Let’s take it clearly as below:

Comparison of RMA and DIN Standard for Conveyor Belts

The Top 5 Rubber Conveyor Belt Manufactures in China 2022-2023(with website & contact info)

What is the difference between PSI and Mpa in conveyor belts and how to convert them to each other?

EP Conveyor Belt Layer is the More, the Better?

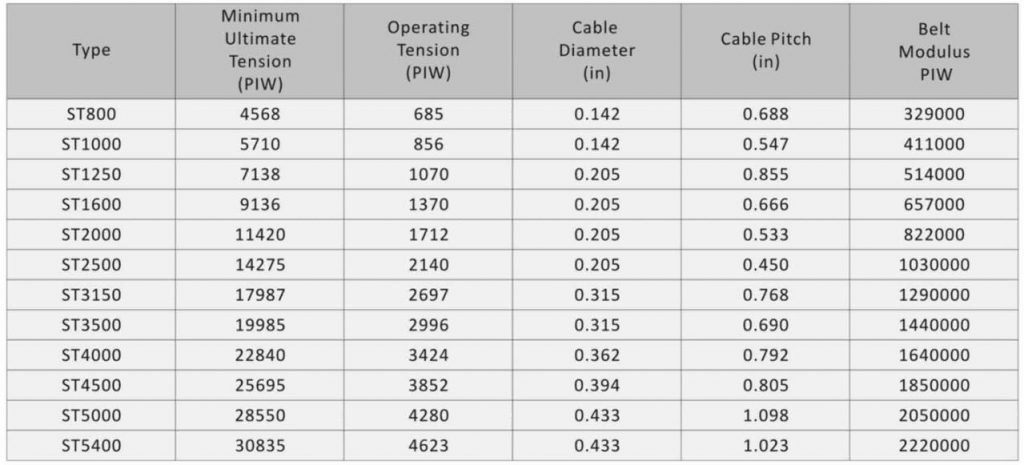

Steel Cord Belt Converting Example:

The above applies to textiles such as EP rubber conveyor belts or NN(Nylon) conveyor belt, for steel cord conveyor belts, the rating in N/mm breaking strength is used in the United States too, the test procedure can be different, for example:

Assuming steel cord conveyor belt that has a standard safety factor = 6.7:1 steel cord type is ST1000, then working strength is:

ST1000 N/mm / SF6.7 = 149.25 N/mm working strength

Then we convert metric to imperial for ST1000 steel cord (single cord):

ST1000 / 6.7 = 149.25 N/mm x 5.71 = 852 PIW or 852 pounds/inch.

Sungda Steel Cord Standard Specification(single cord)

Related Literatures:

Why 87.6% of companies choose Chinese conveyor belt manufactures?

How to choose right EP conveyor belt?

6 Steps to help you judge the quality of the EP conveyor belt in 1 minute.

Top 5 Conveyor Idler Manufactures in China 2022

How to Calculate PIW of Conveyor belt

So why do we calculate PIW? This is because the strength of a conveyor belt, whether it’s the carcass tension rating or ultimate breaking strength, represents the amount of force that can be applied to the belt. For example, a 3 ply conveyor belt is rated at 110 PIW per layer, which equates to 330 PIW conveyor belt. This is the maximum rated tension that the belt can operate without damage, exceeding the belt’s rated tension may cause breakage, overstretching, joint failure, etc., so it is important to calculate the PIW value in advance

Since the conveyor belt is one of the most important components in the conveyor system, it is obviously important to choose the right conveyor belt.

The tension members in a belt carcass provide the longitudinal strength to move the load and also withstand torque from the system start up. Belt tension is normally defined as required PIW (pounds per inch of width) and can be calculated using the following quick method:

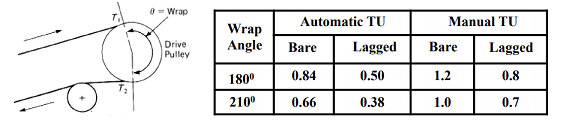

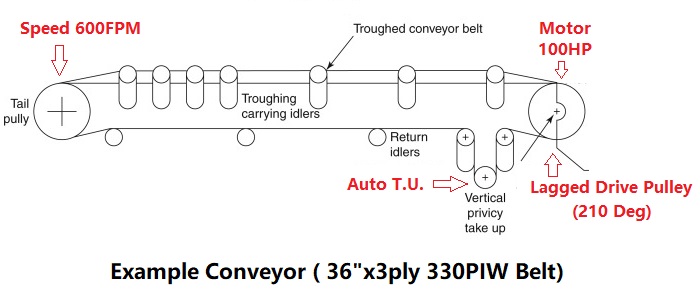

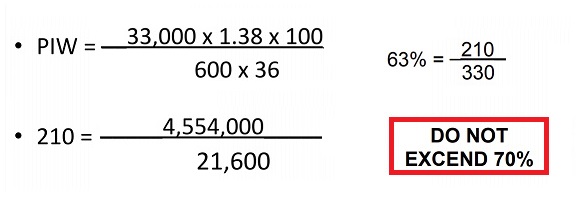

PIW=33,000(1+Cw)HP/SxW

- S = belt speed (ft/min)

- W = belt width (inches)

- HP = motor horsepower (nameplate)

- Cw = drive “wrap factor”

Practical Example:

This is the maximum rated tension that can operate the belt without damaging the belt. Excessive rated tension of the belt may cause breakage, excessive stretching, splicing failure, etc.

Muti-ply EP Fabric Grade (Tensile Strength kg/cm, PIW):

| Carcass | No. of ply | Tensile strength (kgf/cm) | Tensile at break (kgf/cm) | PIW |

| EP160/2 | 2 | 16 | 160 | 89.6 |

| EP200/2 | 2 | 20 | 200 | 112.0 |

| EP250/2 | 2 | 25 | 250 | 142.0 |

| EP315/2 | 2 | 31.5 | 315 | 176.4 |

| EP400/2 | 2 | 40 | 400 | 224.0 |

| EP400/3 | 3 | 40 | 400 | 224.0 |

| EP500/2 | 2 | 50 | 500 | 280.0 |

| EP500/3 | 3 | 50 | 500 | 280.0 |

| EP630/2 | 2 | 63 | 630 | 352.8 |

| EP630/3 | 3 | 63 | 630 | 352.8 |

| EP630/4 | 4 | 63 | 630 | 352.8 |

| EP800/3 | 3 | 80 | 800 | 448.0 |

| EP800/4 | 4 | 80 | 800 | 448.0 |

| EP1000/3 | 3 | 100 | 1000 | 560.0 |

| EP1000/5 | 5 | 100 | 1000 | 560.0 |

| EP1250/3 | 3 | 125 | 1250 | 700.0 |

| EP1250/4 | 4 | 125 | 1250 | 700.0 |

| EP1250/6 | 6 | 125 | 1250 | 700.0 |

| EP1600/4 | 4 | 160 | 1600 | 896.0 |

| EP1600/5 | 5 | 160 | 1600 | 896.0 |

Muti-ply PN Fabric Grade (Tensile Strength kg/cm, PIW):

| Carcass | No. of ply | Tensile strength (kgf/cm) | Tensile at break (kgf/cm) | PIW |

| PN1200 | 2 | 25 | 250 | 140.0 |

| PN1200 | 2 | 25 | 250 | 140.0 |

| PN1200 | 2 | 25 | 250 | 140.0 |

| PN2200 | 2 | 44 | 440 | 246.4 |

| PN2200 | 2 | 44 | 440 | 246.4 |

| PN1200 | 3 | 42 | 420 | 235.2 |

| PN3000 | 2 | 66 | 660 | 369.6 |

| PN2200 | 3 | 66 | 660 | 369.6 |

| PN3000 | 2 | 66 | 660 | 369.6 |

| PN2200 | 3 | 66 | 660 | 369.6 |

| PN2200 | 4 | 88 | 880 | 492.8 |

| PN3000 | 3 | 99 | 990 | 554.4 |

| PN2200 | 4 | 88 | 880 | 492.8 |

| PN3000 | 3 | 99 | 990 | 554.4 |

| PN2200 | 5 | 110 | 1100 | 616.0 |

| PN4000 | 3 | 132 | 1320 | 739.2 |

| PN3000 | 4 | 132 | 1320 | 739.2 |

| PN2200 | 6 | 132 | 1320 | 739.2 |

| PN4000 | 4 | 176 | 1760 | 985.6 |

| PN3000 | 5 | 165 | 1650 | 924.0 |

Muti-ply PP Fabric Grade (Tensile Strength kg/cm, PIW):

| Carcass | No. of ply | Tensile strength (kgf/cm) | Tensile at break (kgf/cm) | PIW |

| PP200/2 | 2 | 20 | 200 | 112.0 |

| PP315/2 | 2 | 31.5 | 315 | 176.4 |

| PP500/2 | 2 | 20 | 500 | 280.0 |

| PP500/2 | 3 | 20 | 500 | 280.0 |

| PP630/3 | 3 | 63 | 630 | 352.8 |

| PP1000/3 | 3 | 100 | 1000 | 560.0 |

| PP1000/5 | 5 | 100 | 1000 | 560.0 |

| PP1240/4 | 4 | 125 | 1250 | 700.0 |

| PP1240/6 | 6 | 125 | 1250 | 700.0 |

| PP1600/5 | 5 | 160 | 1600 | 896.0 |

| PP1600/6 | 6 | 160 | 1600 | 896.0 |

| PP2000/6 | 6 | 200 | 2000 | 1120.0 |

Muti-ply NN Fabric Grade (Tensile Strength kg/cm, PIW):

| Carcass | No. of ply | Tensile strength (kgf/cm) | Tensile at break (kgf/cm) | PIW |

| NN500 | 2 | 21 | 252 | 117.6 |

| NN700 | 2 | 32 | 384 | 179.2 |

| NN1100 | 2 | 52 | 624 | 291.2 |

| NN700 | 3 | 48 | 576 | 268.8 |

| NN1100 | 3 | 78 | 936 | 436.8 |

| NN1800 | 3 | 108 | 1296 | 604.8 |

| NN1100 | 5 | 130 | 1560 | 728.0 |

| NN1800 | 4 | 144 | 1728 | 806.4 |

| NN1100 | 6 | 156 | 1872 | 873.6 |

| NN1800 | 5 | 180 | 2160 | 1008.0 |

| NN1100 | 6 | 156 | 1872 | 873.6 |

| NN1800 | 6 | 216 | 2592 | 1209.6 |

SUNGDA CONVEYOR BELT CO.,LTD.

SUNGDA’s series of conveyor belt products have significantly high quality. Including the abrasion resistance and tensile strength of the cover, tear strength, tensile strength at break, and the adhesion between the ply and the carcass. It also has particularly good low elongation (low stretch) characteristics.

SUNGDA conveyor belt’s carcass is available in 2, 3, 4, 5 and 6 high grade synthetic EP (polyester nylon) fabric layers. They have low stretchability, and have consistent longitudinal and transverse tensile strength, providing first-class handling characteristics and splicing strength.

The above characteristics can greatly extend the service life of the conveyor belt

The width of SUNGDA conveyor belts ranges from 400mm to 4500mm, and the tensile strength ranges from 250 N/mm to 1000 N/mm. SUNGDA conveyor belts can provide all types of using protection such as steel cord conveyor belt, pipe conveyor belt, fire resistance conveyor belt, heat resistance conveyor belt and chevron conveyor belt etc.

SUNGDA conveyor belts provide outstanding reliability and durability in many industries, such as cement, steel mill, chemical and fertilizers, mining, quarries, power plants, recycling, wood, paper and pulp, sugar and food, steel and transshipment.

SUNGDA Conveyor Belt Testing Lab:

Sungda Conveyor Belt Export Packing:

We also supply conveyor idler roller, pulley and conveyor bracket, please log to our branch company official website www.conveyoroller.com or click below picture for idler roller producing video.

SUNGDA Regular Customer:

Related articles:

These adjustment methods can make the conveyor belt transport 50 tons more per hour!

What are the advantages of EP conveyor belts compared to other fabric carcass conveyor belt?

How does the bending of EP fabric affect the working life of the conveyor belt?

How to select heat resistant(HR) conveyor belt?

More articles please click here

Please E-mail us to get a quick quotation in half-hour!

Tags: 220PIW,330PIW,Belt PIW Convert,Conveyor belt PIW,EP conveyor belt,formula,PIW1000,PIW1250,PIW440,PIW500,PIW625,PIW660,PIW800,PN CONVEYOR BELT,PP CONVEYOR BELT,RMA,RMA-I,RMA-II,Rubber conveyor belt,Steel cord conveyor belt,steel mill