What Is The Safety Factor of The Conveyor Belt and How to Choose it?

When we choose or purchase conveyor belts, we will encounter a technical index called “safety factor” (SF), so what is the safety factor and how should we choose the safety factor?

“Safety factors” were first stated in DIN 22101, 1982, it is the figures given by conveyor belt manufacturers for their particular belt styles. The safety factor is the ratio of a material’s breaking strength to the stress applied or maximum load permissible. It is commonly called “Tension”. This figure is connected to the belt’s fabric and therefore the overall strength of the belt. It doesn’t matter if the belt is covered with EPDM, Nitrile, or SBR. The safety factor is independent of these. In other words, the safety factor is an important parameter to ensure that the conveyor belt does not break up during operation.

The safety factor is directly related to our market: from the point of view of safety, reliability and long life, it should be larger, and from the economic point of view, it should be smaller.

The safety factor of the previous conveyor belt is relatively conservative,for fabric belts, belt safety factor is often a nominal 10:1,and steel cord safety factors were a nominal 6.7:1, for example, a manufacturer wants to build a 220 pounds per inch, 2 ply conveyor belt. He desires to set a 10:1 safety factor standard for his product. This means his finished belt breaks on the ‘snatch and grab’ machine at a minimum force of 2200 pound per inch, the result has led to a substantial increase in user investment.

However, more and more studies have shown that the tensile strength of the conveyor belt has nothing to do with the actual safety factor of the conveyor belt design, but is related to the ability of the conveyor belt to withstand the load and the instantaneous peak load under the stable operation state of the conveyor belt and the splicing fatigue strength, that means it is the multiplier applied to the calculated maximum force to which a conveyor belt splice (as the weakest link in a conveyor belt) will be subjected. A factor of safety accounts for imperfections in materials, flaws in assembly, material degradation, and other uncertainties .

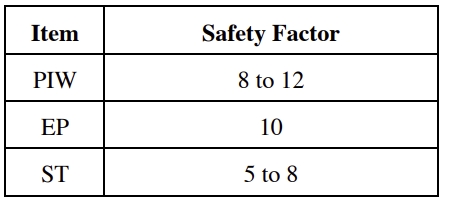

Generally accepted safety factor:

Conventional safety factors usually range from 6,7 to 10 for steady operating conditions, related to the splice strength.

For example, a steel cord conveyor belt from “SUNGDA” has a tensile strength of 7500N/mm, after testing the splicing fatigue strength of the conveyor belt, the splicing efficiency tested by the fatigue machine reached 38%, therefore, the splicing fatigue strength was 2850N/mm (bearing rate=0.38*7500N/mm). Another steel cord conveyor belt from “SUNGDA”, its tensile strength is 6600N/mm, but the splicing technology and strength of the conveyor belt are improved. After the conveyor belt has been tested, its splicing withstand level is 50%, and its net withstand level is 3300N/mm, which is 16% higher than the splicing fatigue strength of the first conveyor belt. Although its tensile strength is 14% lower than the former, the design safety factor of the first conveyor belt is 6.5.

Due to strong splicing strength, the safety factor of the second conveyor belt can be reduced to 4.7, and the corresponding withstand tension is increased by 39%. Conveyor belt and splicing construction materials and modern analysis methods show that it is safe and reliable to use a safety factor lower than 5.0 between the tensile strength of ST-1000N/mm and ST-6000N/mm.

Conveyor belts, especially high-strength conveyor belts, account for as much as 30-50% of the investment in belt conveyors. To choose conveyor belts reasonably and reduce the investment of conveyor belts, an important way is to improve the conveyor belt joint technology in order to reduce the safety factor. For example, a conveyor with a length of 20km in Australia reduces the safety factor of the wire rope conveyor belt from the usual 6.7 to 5.0, the weight of the conveyor belt is reduced by 14%, the life of the bearing roller is increased by 7%, and the life of the return roller is increased by 40%. . The reduction of conveyor belt tension reduces the corresponding structural investment, power consumption is reduced by 4%, and investment and operating expenses can be reduced by about 10% within 20 years of service.

The German Industrial Standard DIN22101-1982 defines the safety factor of the steel cord conveyor belt as the ratio of the tensile strength of the steel cord conveyor belt to the conveyor belt tension when the conveyor is running stably, with a minimum of 6.7. In 2002, Germany revised the original 1982 standard, and the new version adopted a new concept and calculation method. The conclusion is that the safety factor of steel cord conveyor belt can be less than 6.7, and the lowest can be 4.5.

In the past ten years, some countries have already broken through the 1982 regulations. The belt conveyors in operation in Germany, Britain, New England, Australia and other countries have adopted 4.5-5.5. According to the research results of foreign institutions such as the United States CDI Company, the safety factor of the steel cord conveyor belt can be reduced to below 5.5, which can be 4.5 to 5.0.

SUNGDA CONVEYOR BELT COMPANY

SUNGDA Official Website: https://www.sungdagroup.com

Official website: www.sungdagroup.com

Inquiry mail: info@sungdagroup.com

Tags: conveyor belt safety factor,CONVEYOR BELT SELECTION,Rubber conveyor belt