The 4 most critical tips for choosing the right rubber conveyor belt

With the continuous integration and development of globalization, the demand for conveyor belts is also increasing, and the number of conveyor belt manufacturers in the market is also increasing. This has advantages and disadvantages for customers. The good thing is that there are more choices. The downside is that the number of conveyor belt products is dazzling, and it is easy to choose the wrong conveyor belt if you don’t know which conveyor belt to choose. The following three aspects will be analyzed for you, how to choose the most suitable conveyor belt for your own use.

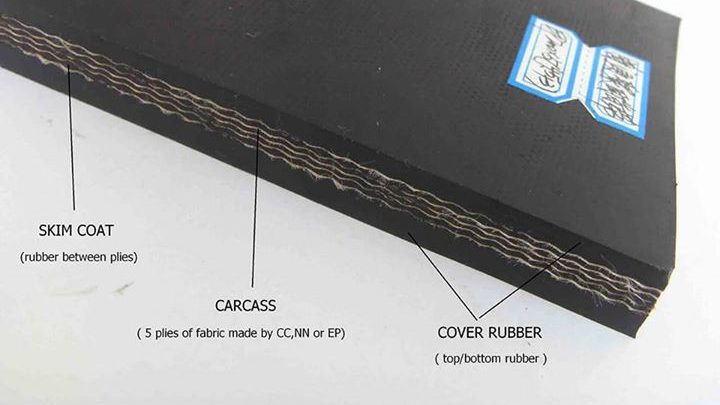

1.Selection of conveyor belt carcass material and structure of conveyor belt: The performance of rubber conveyor belt has a great relationship with the carcass material, structure and number of layers.

Cotton fabric (CC) multi-layer conveyor belts have the characteristics of fatigue resistance, corrosion resistance, light weight and low cost. The disadvantage is that the CC carcass strength is low and the energy consumption is high.

Nylon (NN) conveyor belt has high strength, high elasticity, light weight, good impact resistance, bending resistance, very good troughing forming performance, mildew resistance and water resistance better than cotton fabrics. The disadvantage is that the elongation of the conveyor belt is large.

Polyester (EP) belts are similar in strength to cotton fabrics belts. It has the advantages of nylon belt, and the elastic modulus is higher than nylon. Low elongation and good dimensional stability. It is an ideal conveyor belt commonly used in industry. High strength, small elongation, short tensioning stroke, especially suitable for mass transportation. High belt speed, long distance conveying requirements

2.Selection of cover rubber: The main components of cover rubber are various natural rubber and recycled rubber. Since the properties of various rubbers are also very different, such as natural rubber, styrene-butadiene rubber with good heat absorption capacity and wear resistance, especially EPDM rubber, nitrile rubber with good oil resistance, butyl rubber Therefore, the choice of covering material must be comprehensively considered according to the size of the conveying volume, the nature of the material being transported, the temperature and the operating environment of the conveyor belt.

3.Selection of the thickness of the rubber cover thickness: Increasing the thickness of the additional rubber cover thickness is also conducive to improving the impact resistance and wear resistance of the rubber conveyor belt. In particular, the cotton fabrics carcass has been replaced by a synthetic fiber carcass, and the carcass is to greatly improve the performance, and the thickness is relatively thin. In order to improve the overall performance of the conveyor belt, the thickness of the rubber cover thickness must be increased to give full play. Its advantages can improve the service life of the conveyor belt, but the thickness of the covering layer will make the running resistance of the heavy conveyor belt, which will increase the operating energy consumption and limit the conveying volume, so it must be considered comprehensively. The thickness of the cover is 1.5~3 mm for bottom cover, and the thickness of the top cover rubber is between 2.5~6 mm (the heat resistance belt is 4~8 mm), which is a more economical choice.

4.Selection of the number of layers of the belt carcass: The number of layers of the belt carcass of the conveyor belt is not as much as possible. Excessive number of layers will increase the pressure of the conveyor belt when it passes through the drum, so that the strong layers of the conveyor belt face delamination. Generally speaking, in the case of ensuring the overall strength of the conveyor belt, it is an ideal choice between 3~6 layers

In addition to the above 4 tips, the selection of the rubber conveyor belt plays a decisive role in the size, sharpness of the material, and the specific properties of the material, including: loose density, angle of repose, particle size, lumpiness, and material properties. Humidity, abrasiveness, cohesion and coefficient of friction of the material. In addition, the working environment of the rubber conveyor belt, daily operation time, working frequency, service life, feeding and unloading methods, etc., all directly affect the choice of belt conveyor.

SUNGDA CONVEYOR BELT CO.,LTD

Tags: EP conveyor belt,manufacture,Rubber conveyor belt