How to Convert PIW Conveyor belt to EP Belt?

We all know that “PIW”is an imperial unit used to describe EP conveyor belts, such as 220 PIW/2, 330 PIW/3, or 440 PIW/4, representing Pounds Per Inch of Belt Width. This unit is commonly used in the conveyor belt markets of North and South America to describe the overall tensile strength of EP conveyor belts.

However, in many other countries worldwide, the metric unit N/mm is more prevalent for describing EP conveyor belts. The biggest difference between PIW and N/mm is that PIW describes the “operating tension”, while N/mm describes the “strength at breaking”. For example, the breaking strength of the EP 1000 carcass is 1000 N/mm, after converting to metric (assuming a safety factor of 10:1), the operating tension will be 100 N/mm or 571 PIW in imperial.

As international trade continues to recover, the conversion between these two different units becomes increasingly necessary. So, what does ‘PIW’ mean in conveyor belts, and how can it be converted to EP grade?

Before converting to a specific EP cloth model, we must first convert PIW into metric N/mm units.

How PIW and N/mm convert to each other?

Without consideration of a safety factor, PIW is converted into N/mm(EP) by multiplying by 0.175.

Example: 330PIW x 0.175 = 57.75N/mm(57.75kN/m)

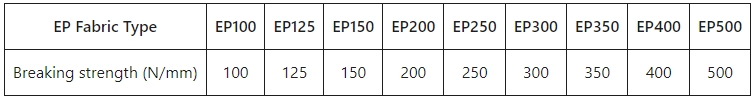

Assuming a 10:1 safety factor, the breaking strength of whole belt will be 57.75N/mm x 10=577.5N/mm, this value is the EP unit, then divide by the number of layers to get the breaking strength of each layer. Check the table below to get the specifications of the EP conveyor belt.

Let us take the most common PIW330/3 conveyor belt as an example: 330PIWx 0.175=57.75. If the safety factory was 10, then the overall strength of the conveyor belt will be 577.5N/mm, and divided this value by 3 EP layers, then each layer of EP fabric strength is 192.5N/mm. According to the above EP model table as below, EP200 is closest to this value, so the EP model closest to PIW330/3 is EP200, 3-layer conveyor belt, which is EP600/3 conveyor belt.

Conversely, N/mm converted into PIW are multiplied by 5.71.

Example: 577.5 N/mm x 5.71 = 3297.5 PIW

Assuming a 10:1 safety factor, the breaking strength of whole belt will be 3297.5 PIW x 10=329.7PIW

(The above conversion is applicable to various conveyor belts types, such as heat-resistant conveyor belts, fire-resistant conveyor belts, chevron conveyor belts and pipe conveyor belts etc.)

According to the table below, we can quickly find out the corresponding PIW specifications according to the EP model.

Muti-ply EP Fabric Grade (Tensile Strength kg/cm, PIW):

| Carcass | No. of ply | Tensile strength (kgf/cm) | Tensile at break (kgf/cm) | PIW |

| EP160/2 | 2 | 16 | 160 | 89.6 |

| EP200/2 | 2 | 20 | 200 | 112.0 |

| EP250/2 | 2 | 25 | 250 | 142.0 |

| EP315/2 | 2 | 31.5 | 315 | 176.4 |

| EP400/2 | 2 | 40 | 400 | 224.0 |

| EP400/3 | 3 | 40 | 400 | 224.0 |

| EP500/2 | 2 | 50 | 500 | 280.0 |

| EP500/3 | 3 | 50 | 500 | 280.0 |

| EP630/2 | 2 | 63 | 630 | 352.8 |

| EP630/3 | 3 | 63 | 630 | 352.8 |

| EP630/4 | 4 | 63 | 630 | 352.8 |

| EP800/3 | 3 | 80 | 800 | 448.0 |

| EP800/4 | 4 | 80 | 800 | 448.0 |

| EP1000/3 | 3 | 100 | 1000 | 560.0 |

| EP1000/5 | 5 | 100 | 1000 | 560.0 |

| EP1250/3 | 3 | 125 | 1250 | 700.0 |

| EP1250/4 | 4 | 125 | 1250 | 700.0 |

| EP1250/6 | 6 | 125 | 1250 | 700.0 |

| EP1600/4 | 4 | 160 | 1600 | 896.0 |

| EP1600/5 | 5 | 160 | 1600 | 896.0 |

Muti-ply PN Fabric Grade (Tensile Strength kg/cm, PIW):

| Carcass | No. of ply | Tensile strength (kgf/cm) | Tensile at break (kgf/cm) | PIW |

| PN1200 | 2 | 25 | 250 | 140.0 |

| PN1200 | 2 | 25 | 250 | 140.0 |

| PN1200 | 2 | 25 | 250 | 140.0 |

| PN2200 | 2 | 44 | 440 | 246.4 |

| PN2200 | 2 | 44 | 440 | 246.4 |

| PN1200 | 3 | 42 | 420 | 235.2 |

| PN3000 | 2 | 66 | 660 | 369.6 |

| PN2200 | 3 | 66 | 660 | 369.6 |

| PN3000 | 2 | 66 | 660 | 369.6 |

| PN2200 | 3 | 66 | 660 | 369.6 |

| PN2200 | 4 | 88 | 880 | 492.8 |

| PN3000 | 3 | 99 | 990 | 554.4 |

| PN2200 | 4 | 88 | 880 | 492.8 |

| PN3000 | 3 | 99 | 990 | 554.4 |

| PN2200 | 5 | 110 | 1100 | 616.0 |

| PN4000 | 3 | 132 | 1320 | 739.2 |

| PN3000 | 4 | 132 | 1320 | 739.2 |

| PN2200 | 6 | 132 | 1320 | 739.2 |

| PN4000 | 4 | 176 | 1760 | 985.6 |

| PN3000 | 5 | 165 | 1650 | 924.0 |

SUNGDA CONVEYOR BELT CO.,LTD.

Tags: 220PIW,330PIW,Belt PIW Convert,EP conveyor belt,formula,N/mm,RMA CONVEYOR BELT,RMA-I,RMA-II