Fire Resistant Conveyor Belt(DIN-K)

Application Background:

The use of fire-resistant (also called flame-resistant) conveyor belts (DIN-K) in coal mines is conducive to reducing the incidence of both above ground and underground fires. The working environment of coal mines is relatively complicated, coal dust and gas are dangerous factors, and the coal mines being transported are also flammable substances, if electric sparks are generated during transportation, it is easy to cause fires. The use of fire-resistant conveyor belts for coal mines reduces the possibility of electrostatic sparks during coal transportation, and even if static sparks occur, the fire-resistant conveyor belts for coal mines have high flame resistance and will not catch fire.

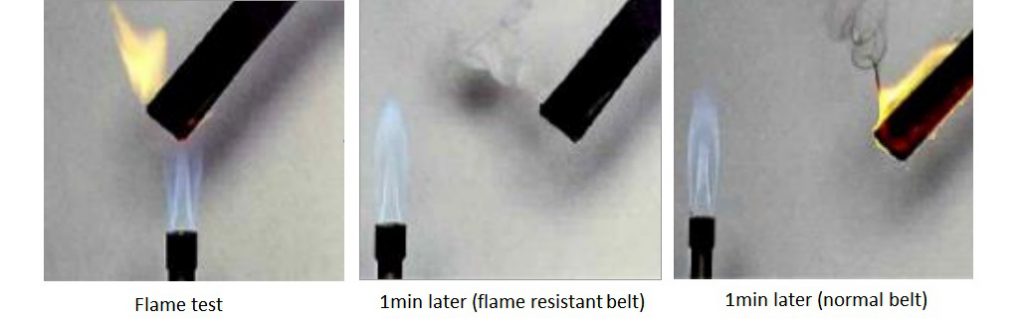

Fire Resistant Capability Test:

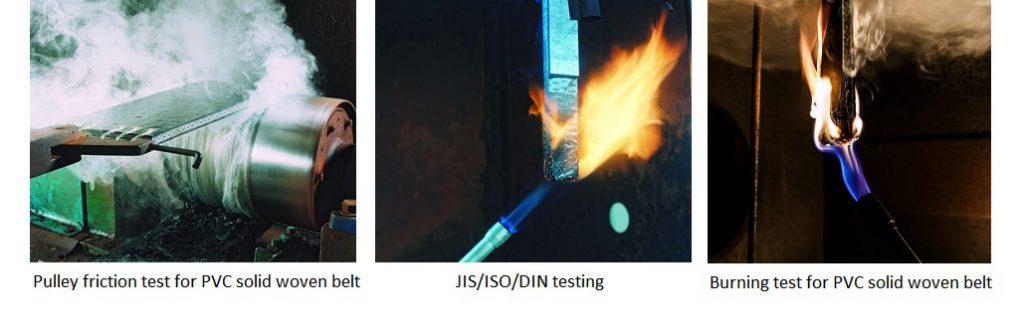

JIS/ISO/DIN tests involve exposing six individual samples of a belt to a naked flame, causing them to burn, the source of the flame is then removed and the combustion time (duration of flame) of the test piece is recorded, a current of air is then applied to the test piece for a specified time after the removal of the flame, the flame should not reignite. The time it takes for the belt sample to self-extinguish after the source of ignition (flame) has been removed is then measured. The duration of continued burning (visible flame) should be less than 15 sec. for each sample, with an absolute maximum cumulative duration of 45 sec.

Pulley friction test is the single biggest difference in the safety classifications (standards) between belting used above ground and belting used underground. If certification is required, then these tests must be carried out by an independent test organization. The test standards demand that there should be no evidence of flame or glow during or after the test. This is only achievable by using a PVC belt because the thermoplastic melts/breaks before it reaches 325˚C, the SUNGDA maximum average is around 260 – 270˚C.

The fire-resistant management of coal mine fire-resistant conveyor belts must be done in the selection of conveyor belts, and the conveyor belts should be selected according to the different underground coal mine use conditions. At present, there are mainly three types of fire-resistant conveyor belts for coal mines: fabric layer fire-resistant conveyor belts, steel cord conveyor belts, solid woven conveyor belt. Among the three types of fire-resistant conveyor belts for coal mines, the first type of conveyor belt, that is, the fabric layer conveyor belt for coal mines is widely used, with a market share of more than 80%, has stronger flame retardant, and has lower weight and cost.

Fire Resistant Test Internation Standards:

| Item | Laboratory flame test | Drum friction | Electric | Others | |||

| Standard | Flame | Glow | |||||

| JIS | Each less than 15sec. Total of 6 samples Less than 45sec. | None | None | None | None | ||

| ISO | Each less than 15sec. Total of 6 samples Less than 45sec. | None | None | Less than 3×108Ω |

None | ||

| DIN-K | Each less than 15sec.Total of 6 samples Less than 45sec. | None | None | Less than 3×108Ω |

None | ||

| MSHA (USA) | Avr. Less than 60sec. | Avr. Less than 180sec. | None | Less than 3×108Ω |

None | ||

| AS (Australia) | Avr.less than 10sec. Each less than 15sec | Avr. Less than 120sec. Each less than 180sec. | Less than 325℃ on drum surface & no glow |

Less than 3×108Ω |

Oxygen index test (ISO 4589) Gallery flame test |

||

| CSA (Canada) | Avr.less than 60sec. | Avr. less than 180sec. | Less than 400℃ on drum surface & no glow |

Less than 3×108Ω |

None | ||

Fire resistant conveyor belt carcass type:

Solid woven carcass: This type of carcass woven by Polyester and Nylon filament, dipped through PVC and plasticized, with characteristics of high tensile strength, small elongation, non-peel off, light-body, no delamination, impact resistance, and tear-performance. Mainly applicable to the underground coal mine and other anti-static fireplaces

EP carcass: EP fabric includes polyester toward longitudinal (warp) and polyamide for latitude (weft), with lower longitudinal elongation, full resistance to mildew, moisture and rotting, good flexibility and trough ability. Suitable for middle and long-distance transportation of higher load and speed in the above-ground mining site.

Steel cord carcass: steel cord has super high tensile strength, good trough ability, high adhesion between rubber and steel cord, this type of fire-resistant belt is suitable for large span, long-distance transportation of materials.

Comparison of RMA and DIN Standard for Conveyor Belts

The Top 5 Rubber Conveyor Belt Manufactures in China 2022-2023(with website & contact info)

What is the difference between PSI and Mpa in conveyor belts and how to convert them to each other?

EP Conveyor Belt Layer is the More, the Better?

SUNGDA CONVEYOR BELT CO.,LTD.

The rubber profile ready for package

Tags: Anti-static properties of fire resistance conveyor belts,Applications and industries of fire resistance conveyor belts,Case studies and successful applications of fire resistance conveyor belts,Chemical corrosion resistance of fire resistance conveyor belts,Comparison between fire resistance conveyor belts and other types,Design and manufacturing standards for fire resistance conveyor belts,DIN-K,Emergency response measures for fire incidents involving conveyor belts,Environmental characteristics and sustainability of fire resistance conveyor belts,Fire resistance grades and certifications for conveyor belts,Fire resistance performance testing standards for conveyor belts,fire resistant conveyor belt,fire retardant conveyor belt,Flame resistant conveyor belt,Flame retardant conveyor belt,FR conveyor belt,Heat stability and high-temperature resistance of fire resistance conveyor belts,Importance and role of fire resistance conveyor belts,Industry standards and regulations for fire resistance conveyor belts,Installation and maintenance tips for fire resistance conveyor belts,Lifespan and durability of fire resistance conveyor belts,Materials and construction of fire resistance conveyor belts,Pricing and costs of fire resistance conveyor belts,PVC,PVG,Research and innovation trends in fire resistance conveyor belts,Selection and buying guide for fire resistance conveyor belts,Suitable environments and conditions for fire resistance conveyor belts,underground mining fire resistance conveyor belt