How to make the heat-resistant conveyor belt can reach the level of 800 °C?

The existing conveyor belt is composed of a lower covering rubber layer, a carcass layer, an upper covering rubber layer and an edge rubber. The carcass layer is made of heat-resistant canvas material (EP, NN, etc.). This rubber conveyor belt is only suitable for conveying 85°C. The following non-high temperature materials, but in the steel, cement, chemical and other industries, the main products are high temperature materials such as sinter, coke, cement clinker, lime, etc. Due to the high temperature of these materials, the material temperature of sinter is generally 500℃-800℃, and some even reach thousands of degrees. This kind of rubber conveyor belt cannot withstand high temperature burning for a long time, and the surface will fall off due to scalding or burning, and the heat will flow from the damaged surface to the surface. Rapid transmission in the interior, resulting in the destruction of the carcass material, reducing the strength of the conveyor belt, affecting the service life of the conveyor belt, reducing the use efficiency of the conveyor belt and increasing the cost of use;

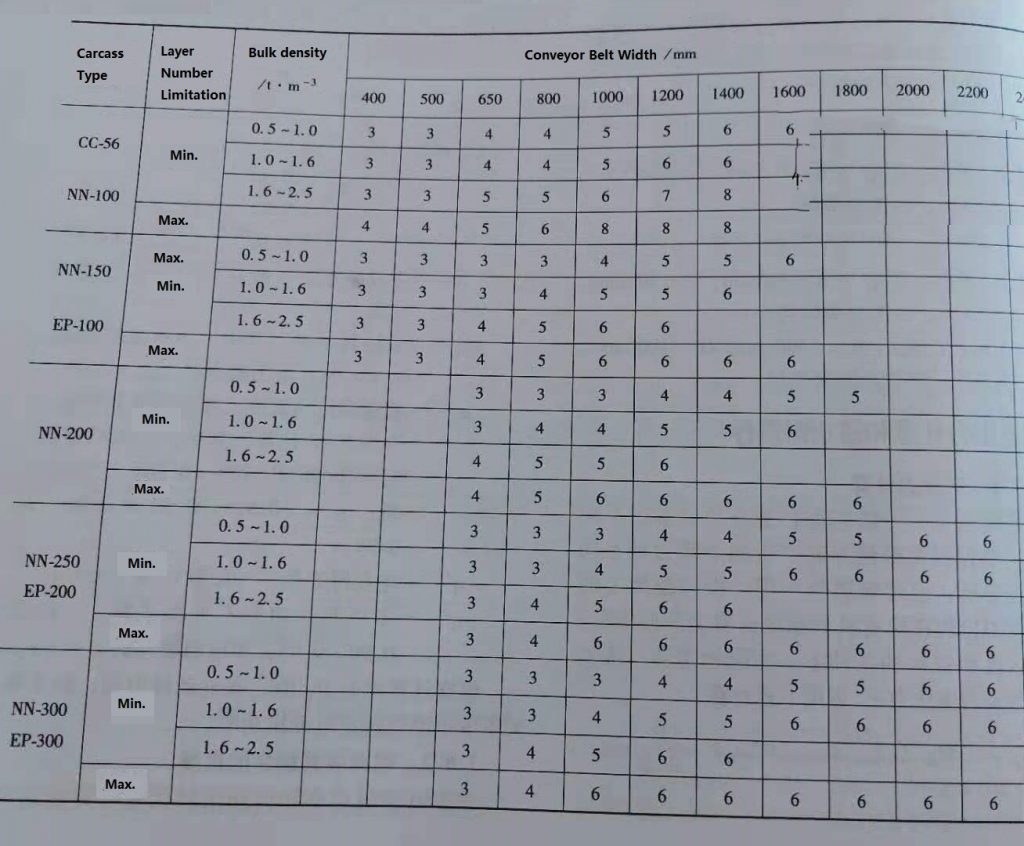

Through technical improvement and product performance innovation, the industrial conveyor belt is designed to be composed of a bottom-up lower covering rubber layer, at least one carcass layer and an upper covering layer. Both sides of the carcass layer are provided with upper and lower covering rubber layers. The edge glue of one-piece structure, the main feature of this structure is that there is a high-strength heat insulation layer made of glass fiber or polyurethane between the carcass layer and the upper covering glue, and the burning-resistant layer is made of styrene-butadiene material with a thickness of 2 -6 mm, the carcass layer made of heat-resistant glass fiber canvas is 1-6 layers, and the layers are bonded with high-temperature resistant styrene-butadiene glue;

Through the overall arrangement of the above structures, a very obvious characteristic application effect can be achieved:

First, the anti-burning layer can quickly form a microporous carbonized layer after contacting with high-temperature and hot materials, which can isolate the heat transfer to the interior of the conveyor belt and protect the carcass layer. The carbonized layer has the properties of flame retardant and wear resistance. ;

Second, the carcass material selects inorganic modified materials with low strength loss and no deformation at high temperature, such as modified glass fiber canvas. Its novel canvas structure not only ensures the required strength of the belt body, but also improves the flexibility of the canvas. And the adhesiveness of rubber and carcass material;

Third, the carcass layer is bonded with high temperature resistant adhesive, which solves the problem of low interlayer adhesion strength under high temperature conditions, and ensures that the interlayer adhesion strength of the belt body remains stable at 160 °C, which is the same state as ordinary heat-resistant conveyor belts. More than twice the bond strength between the lower layers;

Through the innovation of the above structure, we have ensured the normal use of the transport belt under high temperature conditions and extended the service life. It can be adapted to the working conditions of various high-temperature materials with a transport temperature of 200-600 °C and an instantaneous temperature of 800 °C. Its burning resistance is excellent, and it is 3-4 times the service life of ordinary high temperature belts under the same use environment.

Due to its good characteristics, this anti-burning conveyor belt is suitable for high-quality conveying of high-temperature materials such as sinter, coke, cement clinker, and lime。

Tags: fire resistant conveyor belt,Heat resistant conveyor belt