How to effectively extend the service life of heat-resistant conveyor belts?

Heat-resistant conveyor belt, as you know, is a conveyor belt with characteristics for use in high temperature environments. Heat-resistant conveyor belts are widely used in steel, cement, chemical and other industries.

Features: When the covering rubber is exposed to high temperatures, a microporous carbonized layer will be produced. This layer has heat resistance and can prevent further heat transfer to the belt carcass, thereby reducing the internal strength of the conveyor belt. The carbonized layer will produce small irregular cracks during belt operation, which are cooled by the belt.

The heat-resistant conveyor belt is mainly used for conveying high temperature materials, such as sintered ore, hot coke, cement clinker, hot castings, etc. It varies according to the main performance damage of the heat-resistant conveyor belt and the loss of conveying capacity. The heat-resistant grade is EPDM or styrene-butadiene rubber (SBR) as covering rubber; high-strength and high-permeability polyester (EP or NN) fabric or Cotton fabric is used as the carcass. It is suitable for conveying hot coke, cement, slag and hot castings below 175°C. .

In order to extend the service life of the heat-resistant conveyor belt, the following points should be noted:

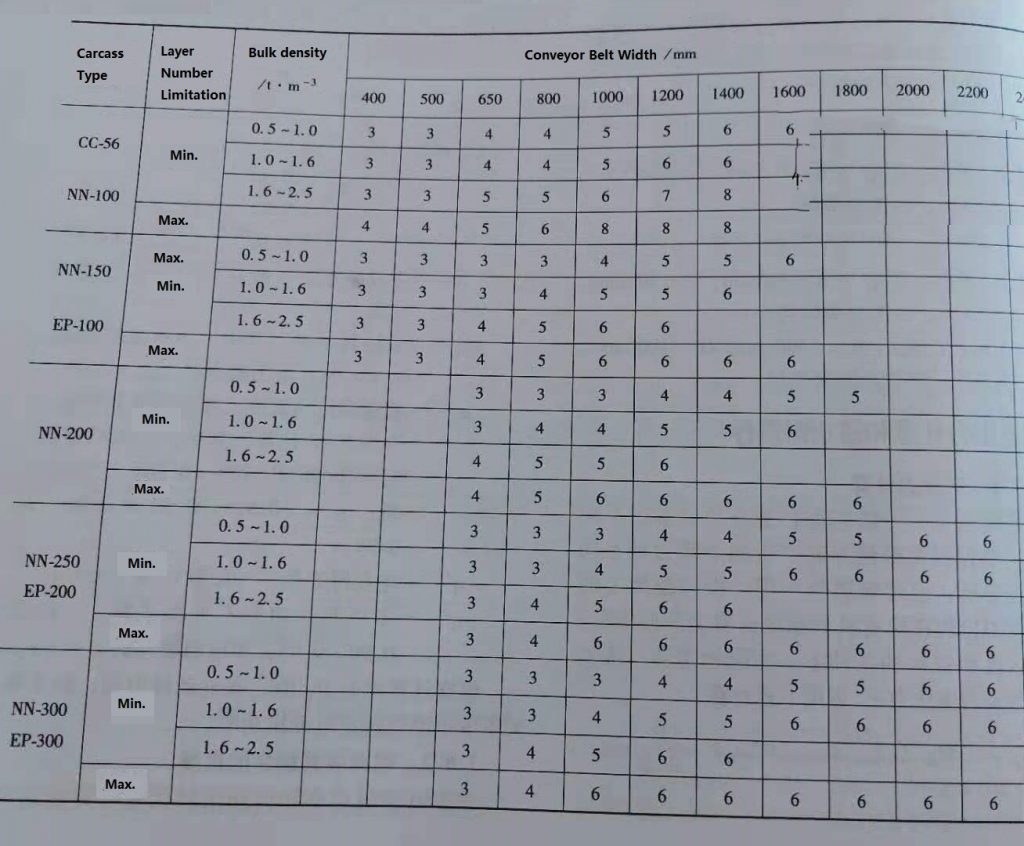

1. The rubber surface of the heat-resistant conveyor belt should be as thick as possible to prolong the service life of the conveyor belt and reduce the damage of high-temperature materials to the carcass and degreased rubber. Our suggestion is that the top cover is no less than 5.5mm and the bottom cover is no less than 2.5mm

2. The feeding direction should follow the running direction of the conveyor belt. In order to reduce the impact of high temperature materials on the conveyor belt, a chute should be used to reduce the distance the material falls. The receiving part of the heat-resistant conveyor belt should shorten the interval between the conveyor rollers. The heat-resistant conveyor belt should use a soft and moderate baffle to prevent the baffle from being too hard and scratching the surface of the heat-resistant conveyor belt.

3. Before blanking, the feed inlet should have cooling spray equipment to cool the surface of the conveyor belt, and there should be fan equipment on the return journey, which can effectively reduce the surface temperature of the conveyor belt.

4. The conveying distance should not be too long, so as to shorten the residence time of high-temperature materials on the conveyor belt as much as possible, and at the same time, the return distance can be used to cool the belt body of the conveyor belt as soon as possible.

5. The diameter of the conveyor pulley should not be too small, so that the cracked part of the heat-resistant conveyor belt is not easy to expand in depth. If the diameter of the conveyor pulley is too small, it will accelerate the spread of the cracked part of the conveyor belt, thereby endangering the carcass of the heat-resistant conveyor belt.

A reasonable conveyor pulley diameter can also reduce the pressure between the carcass and the cover rubber, also between EP fabric layers, thereby reducing the possibility of delamination and bulging caused by high temperature. Under normal circumstances, for EP800/4ply, 6mm+2mm heat-resistant conveyor belts, the conveyor pulley diameter should not be less than 630mm.

6. Absolutely prohibit the sudden shutdown of the conveyor line, which will cause the temperature at the bottom of the high-temperature material to rise sharply, exceeding the heat resistance of the conveyor belt, and thus damage the heat-resistant layer and carcass of the conveyor belt.

7. The running speed of the heat-resistant conveyor belt should generally not be greater than 2.5m/s. However, if the conveying distance is too long, the belt speed can be appropriately increased, which can reduce the residence time of high-temperature materials on the conveyor belt and reduce the damage to the surface of the conveyor belt.

8. When using the conveyor, if the roller is missing or damaged, it should be supplemented or repaired in time to prevent the damaged or stalled roller from damaging the conveyor belt.

9. Prevent high-temperature materials from leaking and jamming between the conveying roller and the conveyor belt. This will cause high-temperature materials to damage the rotating part of the roller and reduce the service life of the roller. Pay attention to frequent lubrication of the rotating parts of the roller, but do not Contact the oil to the heat-resistant conveyor belt, otherwise it may corrode the belt body of the conveyor belt.

10. Pay attention to check the temperature of high temperature materials at any time. If the temperature is too high, measures should be taken immediately to reduce the temperature of the material, and measures should be taken to cool the belt.

11. The use site of the heat-resistant conveyor belt should also be well ventilated, which will also help the conveyor belt to maintain a reasonable working temperature.

Tags: cement plant,Heat resistant conveyor belt