How to select the layers of heat resistant conveyor belt

The fabric conveyor belt is designed for conveying various items with special performance in different regions and under environmental conditions. The conveyor belt carcass structure is mainly for cold, oil, heat, high temperature, and chemical corrosion resistant conveyor belts. With . It can be suitable for conveying under different conditions of different regions, different cold and hot conditions, and various bulk materials such as food, chemical products, etc.

Ordinary high temperature resistant fabric conveyor belt refers to the conveyor belt with fabric layer and fabric layer as the : including ordinary high temperature resistant cotton fabric conveyor belt, heat resistant nylon conveyor belt, heat resistant conveyor belt and so on. These together constitute the basic structure of a heat-resistant ordinary conveyor belt, and among these, the advantages of polyester fabric(EP) are far greater than nylon fabric and ordinary cotton fabric.

Pay attention to the following points when selecting high temperature resistant fabric conveyor belt:

1 For short-distance belt conveyors, polyester fabric conveyor belts should be used. Steel cord conveyor belts should be used for belt conveyors with large transport capacity, long transport distance, large lifting height, and high tension.

2 The material being conveyed contains large lumps. And when the direct drop of the receiving point is large, the impact-resistant and tear-resistant conveyor should be selected.

3 The maximum number of layers of the layered fabric conveyor belt should not exceed 8 layers: when the conveyed material has special requirements for the thickness of the conveyor belt, it can be appropriately increased.

4 Flame-retardant conveyor belts must be used for underground belt conveyors.

The number of layers Z of cotton, nylon, polyester and other fabric conveyor belts is calculated as follows:

Z=(Fmax*n)/B*σ

Where Fmax—-the maximum tension of the conveyor belt under stable conditions, N;

B—-Conveyor belt width, mm;

σ —longitudinal breaking strength of conveyor belt, N/(mm*layer)

n —Static safety factor of fabric conveyor belt under stable working conditions; cotton fabric belt: n=8~9; nylon, polyester fabric belt: n=10~12, when the use conditions are harsh or special safety is required , N should be greater than 12.

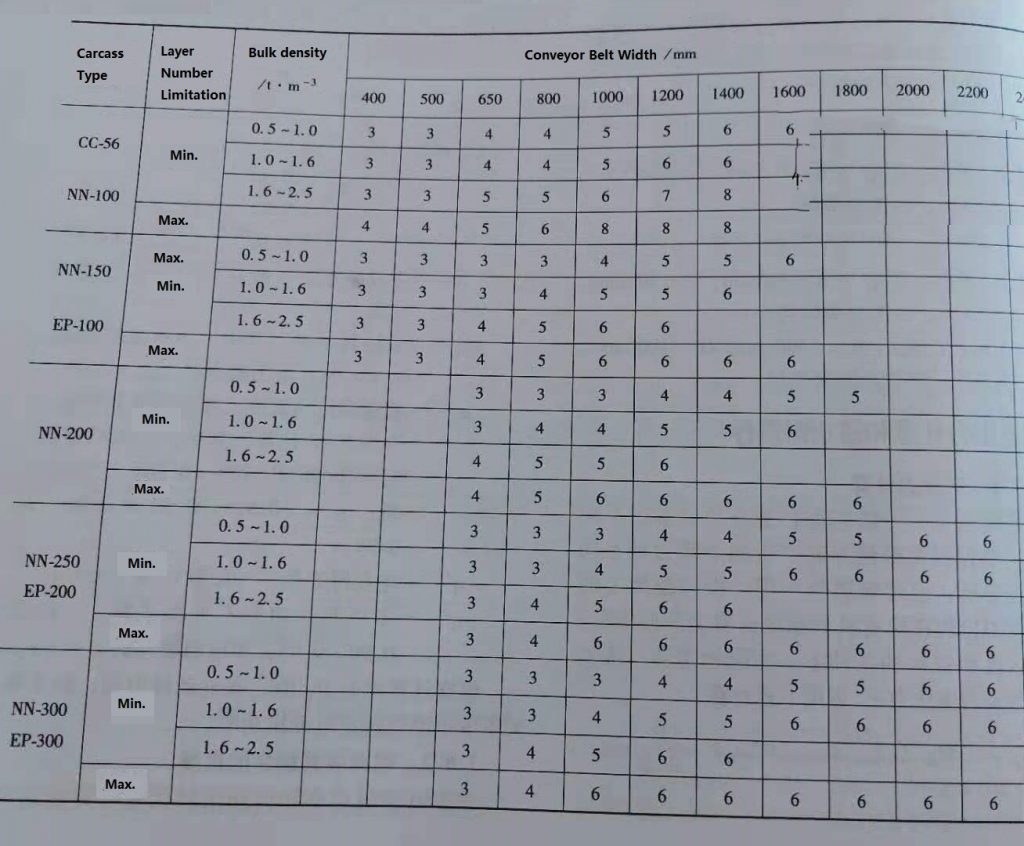

When determining Z, it should be selected within the range specified in the following table:

Tags: conveyor belt layer selection,EP conveyor belt,Heat resistant conveyor belt