Common causes and solutions for sagging of EP conveyor belts

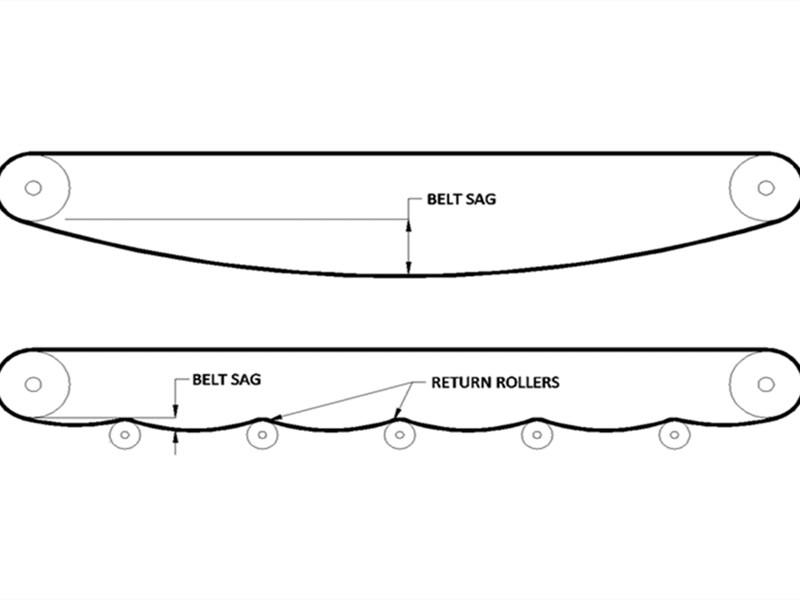

Excessive sagging of the EP conveyor belt refers to the phenomenon that the sagging amount of the conveyor belt exceeds the design or appropriate range during use. Excessive sagging will cause the EP conveyor belt to loosen and lose its normal tension, resulting in a decrease in transport capacity and prone to problems such as slipping and deviation. In addition, excessive sagging will accelerate the wear and aging of the EP conveyor belt, reduce its life, increase the failure rate and maintenance costs. Therefore, the reasonable installation, tension control, maintenance and replacement of the conveyor belt are very important to ensure the normal operation and service life of the EP conveyor belt.

The common causes and solutions of the sagging of the EP conveyor belt are as follows:

- Improper belt installation causing apparent excessive EP conveyor belt stretch:

Pulley belt through counterweight with a tension equal to at least empty running tension; Run EP belt in with mechanical fasteners.

2. Improper initial positioning of counterweight in its carriage causing apparent EP conveyor belt sagging:

Consult ContiTech R&D department for recommended initial position DIN22101 section 10.3 recommended the ratio be ≤3.

3. Insufficient counterweight travel:

4.Tension too high:

Increase speed, same tonnage; Reduce tonnage, same speed; Reduce friction with better maintenance and replacement of damaged idlers; Decrease tension by increasing arc of contactor go to lagged pulley; Reduce CWT to minimum amount.

5.Counterweight too heavy:

Lighten counterweight to value required by calculations.

6.System underbelted:

Recalculate belt tensions and select proper EP conveyor belt.

7.Excessive elongation due to age or wear:

Replace the worn or aged EP conveyor belt with a new one.

8.Insufficient belt support:

Provide adequate support for the EP conveyor belt to prevent sagging and excessive elongation.

9.Improper EP conveyor belt selection:

Select a EP belt with appropriate characteristics for the specific application, such as material, strength, and thickness.

10.Incorrect belt tensioning:

Ensure proper tensioning of the belt using tensioning devices such as take-up screws or gravity take-ups.

Over-sagging of EP conveyor belts can be caused by various factors, such as improper installation, incorrect tensioning, insufficient counterweight travel, and excessive belt age or wear. Proper solutions include recalculating belt tensions, adjusting the counterweight, selecting the appropriate belt, and providing adequate belt support. Regular inspection and maintenance can also help prevent excessive EP belt elongation.

Tags: EP conveyor belt,OVERSTRETCHING