7 Common Causes of Conveyor Belt Tearing and What are the Preventive Measures?

The tearing of the conveyor belt generally has two categories: transverse tearing and longitudinal tearing. Most of the transverse tearing is caused by the rupture of the steel cord or EP fabric in the conveyor belt, which generally belongs to the quality problem of the conveyor belt itself, and it is difficult to prevent and control it on site. Longitudinal tearing is due to the hard object pressing the belt during the operation. When the bearing limit of the conveyor belt is reached, the conveyor belt is pierced, and the conveyor belt continues to run, causing the puncture hole to be stretched, which may cut the entire conveyor belt.

Longitudinal tear location

The longitudinal tear of the conveyor belt mainly occurs at the loading point at the tail of the machine. The main reason is that the materials falling from the blanking port often carry foreign objects. These foreign objects usually have sharp edges, which can easily puncture the conveyor belt. When these foreign objects fall and get stuck on the blanking port, shelf or conveyor idler, they will form top pressure and continuous scratching on the surface of the conveyor belt, and the tighter the stick, the more pressure on the conveyor belt, making it the scratches to the conveyor belt deepen rapidly, eventually piercing the conveyor belt and forming a tear strip. If it is found in time, braking the belt immediately can also reduce losses. If not detected in time, there will be serious consequences.

The main reasons for the tearing of the conveyor belt are as follows:

(1) The conveyor belt is torn due to impurities in the conveyed material.

There are two cases of tearing caused by impurities in the material:

The conveyed material is doped with foreign objects, such as sharp ores, metal fragments and other sundries, which will cause local damage to the conveyor belt body when falling. Running forward at high speed causes longitudinal tearing of the conveyor belt.

There are large pieces of material entrained in the material, which are stuck between the hopper baffle and the buffer roller, or between the roller frame and the conveyor belt in the return section, scratching and pressing the conveyor belt for a long time, once the surface of the conveyor belt is punctured or scratched, the wound will deepen rapidly, and finally cut through the conveyor belt, forming a tearing phenomenon.

Therefore, the removal of large pieces of material and foreign objects contained is the key to preventing the tearing of the conveyor belt.

(2) The conveyor belt is torn due to improper installation of auxiliary equipment of the belt conveyor.

In addition to the threat of the material itself, during the transportation process, the falling off of the parts of the conveyor itself is also a major cause of tearing. For example, the falling off of the vibrator lining plate, the hammer head of the pulverizer, and the adjusting block of the blanking port may cause the conveyor belt to tear.

(3) The conveyor belt is torn due to the imperfect structure of the belt conveyor.

The design of the belt conveyor is unreasonable, and the drop of the blanking point at the tail of the machine is large (the maximum drop in the operation area is nearly 10 meters), which causes the material to impact the lower conveyor belt at a high speed, and it is easy to insert the conveyor belt at the blanking point. Cause the conveyor belt to tear.

(4) Conveyor belt tearing caused by material blocking.

The size of the transfer chute is small, which is easy to hinder the passage of materials and impurities and cause the conveyor belt to tear.

(5) Tear caused by the falling of the intermediate idler.

The conveyor belt is directly pressed on the bracket supporting the intermediate idler, and the heavy load makes the conveyor belt press against the bracket, and the bracket cuts through the conveyor belt like a knife, causing tearing.

(6) Tear at the conveyor head.

Because the machine head is full of materials, the material wedges between the drum and the connecting beams on both sides of the machine head, causing tearing; or the conveyor belt is torn by sharp foreign objects such as metal wires hanging in the middle of the scraper of the machine head cleaner.

(7) Conveyor parts failure caused tearing.

If the end cap of the conveyor idler is not welded, the rotating end cover cuts the conveyor belt like a rotating blade. When the EP cloth or wire rope in the conveyor belt breaks, the broken wire rope end will be exposed to the outside of the cover rubber from the joint of the conveyor belt, the sticky mouth or the place with serious wear. When the exposed steel cord or EP cloth strip reaches a certain length, it may be twisted into the pulley, conveyor idler, etc., with the operation of the conveyor belt, the wire rope will be pulled out from the cover rubber of the conveyor belt, resulting in core pulling and tearing.

Conveyor belt tear prevention measures

In order to prevent the tearing of the conveyor belt, the following measures should be taken:

(1) Strengthen control from the source of materials, clean up bulky materials, increase impurity removal equipment, and reduce the threat of foreign objects and bulky materials to the conveyor belt.

(2) Strengthen inspections, increase the inspection frequency of post inspections and professional spot inspections, so that problems can be discovered and dealt with in a timely manner.

(3) Improve the conveyor structure, reduce the impact, reduce the material speed, and reduce the possibility of impurities inserting into the conveyor belt by reducing the drop of the blanking point, increasing the buffer baffle, and the fine material falling before the bulk material.

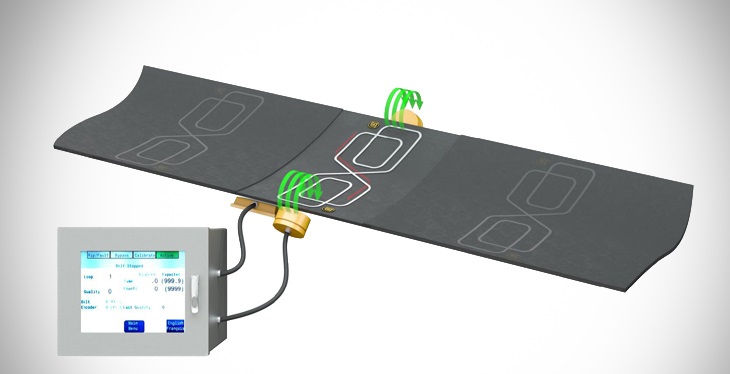

(4) A tearing detection device is added. When the conveyor belt is torn, it will be detected as soon as possible in the shortest time, an alarm signal will be issued and the machine will be stopped to minimize the tearing length and reduce losses. However, the tearing of the belt is caused by various factors, and the tearing of the conveyor belt cannot be completely avoided at present. The currently used conveyor belt tear-proof device and detection device are mainly tear detection devices, which are generally located at the blanking point and consist of sensors and controllers. The sensor is installed under the conveyor belt or beside the chute, and the controller is installed on the machine side or indoors. When the debris tears the conveyor belt, the debris or material that penetrates the conveyor belt squeezes the sensor. The sensor sends a signal to the controller, the controller sends an alarm signal and shuts down.

(5) Use tear-resistant conveyor belt.

The tear-resistant conveyor belt uses steel wire rope as the longitudinal skeleton material, and adds transverse reinforcement to the belt body as the tear-resistant layer. cloth); the other is to use a transverse rope (steel wire or chemical fiber rope). The cover layer is made of high strength, high elasticity and good wear resistance.

(6) Use a conveyor belt that can detect tearing.

A sensor with a closed coil is added to the conveyor belt, the detector is installed on the easy-to-break part of the belt conveyor, and the detector is connected to the controller. When the conveyor belt is running normally, the sensor passes the detector, and the detector emits a pulse. When the conveyor belt is torn, the sensor coil is cut off, and when the sensor passes through the detector, the detector stops sending out pulses. After the controller accepts it, it sends out an alarm signal and stops.

(7) Take measures to prevent the tearing of conveyor belts from the perspective of management.

Through the analysis of the above situation, the anti-tear conveyor belt should first be manned from the management point of view, strengthen material quality control, strengthen equipment management, and carry out impurity removal control; in addition, from a technical point of view, the following measures can also be taken:

Strengthen daily maintenance to reduce failures and malfunctions. Ensure that various protections are reliable, and any abnormal operation is strictly prohibited.

Put forward higher technical requirements for the quality of the conveyor belt and improve the wear resistance of the cover rubber.

The detection effect of the belt tear detection device and the belt tear record are introduced into computer management.

Establish testing methods and systems for conveyor belts, seek truth from facts and long-term tracking record analysis, compare costs and benefits, etc., and draw correct conclusions.

Tags: EP conveyor belt,Steel cord conveyor belt,tearing