What are the Basic Indicators that Determine the Quality of Conveyor Belts?

As an indispensable part of industrial production, the quality assessment of rubber conveyor belts involves multiple key indicators. In this article, we will focus on the three main indicators for rubber conveyor belt quality evaluation: Tensile strength, Elongation at break, and Abrasion loss, and support our arguments with data and actual cases.

First of all, tensile strength is one of the key indicators of EP conveyor belts. High tensile strength means the belt can withstand greater pulling forces, reducing the risk of breakage and damage. Tensile strength includes the tensile strength of the rubber cover and the tensile strength of the overall conveyor belt. The tensile strength of the rubber cover is generally expressed in MPa (Megapascal). The highest tensile strength of the rubber cover currently is 25Mpa. The overall tensile strength of the conveyor belt is related to the strong layer (such as EP fabric and Steel cord) and is often expressed in N/mm. Because the tensile strength of the strong layer of the conveyor belt is much higher than the strength of the rubber cover, the tensile strength of the strong layer The tensile strength is equal to the overall tensile strength of the conveyor belt. For example, the tensile strength of EP200 is 200N/mm per layer, then the overall tensile strength of a 3-layer conveyor belt is 600N/mm. For steel cord conveyor belts, such as ST1000 The overall longitudinal tensile strength of the conveyor belt is 1000N/mm.

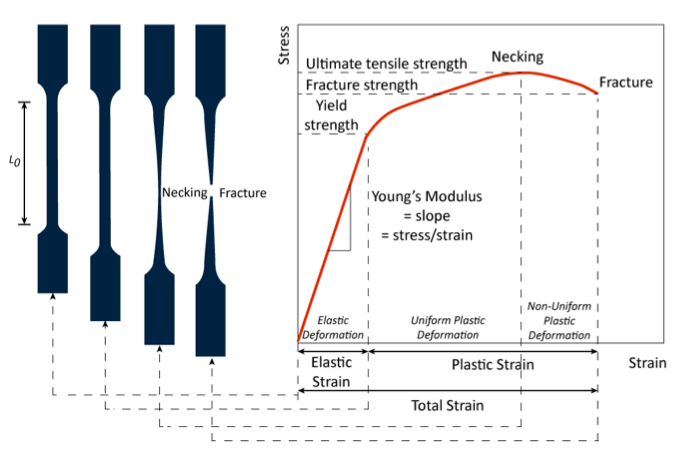

Secondly, the elongation at break, the elongation at break in rubber (also known as the elongation at break) refers to the maximum deformation that occurs before the rubber sample breaks when it is subjected to tensile force. The increased length is the same as the original length. Expressed as a ratio, usually expressed as a percentage. It indicates the maximum degree of deformation the rubber can withstand before failure. The unit is percentage (%).

High elongation at break means that the conveyor belt can deform to a certain extent without breaking immediately when subjected to tension. Some high-quality rubber conveyor belts have an elongation at break of over 20%, which means they are able to maintain their shape when subjected to tension, reducing the risk of damage.

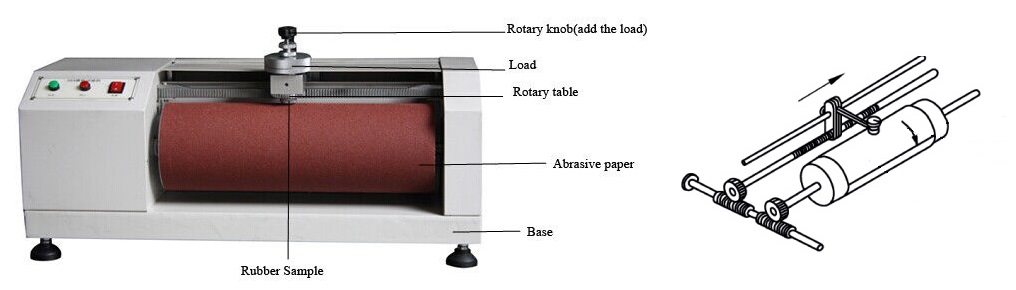

Finally, abrasion loss is an important parameter in evaluating the durability and service life of rubber conveyor belts. Good abrasion resistance means the conveyor belt can maintain stable performance during long-term transportation, reducing maintenance costs and downtime. Some high-quality EP conveyor belts have excellent performance of less than 0.1 grams of wear per square centimeter, which is far better than the approximately 0.5 grams of low-quality conveyor belts. These data show that abrasion resistance is another key factor in evaluating conveyor belt quality.

By comparing the data of conveyor belts of different qualities, it can be clearly seen that tensile strength, elongation at break and abrasion are key indicators for evaluating the quality of rubber conveyor belts. High-quality conveyor belts usually have high tensile strength, elongation at break and good wear resistance, and can provide stable and efficient conveying solutions in industrial production.

SUNGDA CONVEYOR BELT CO.,LTD.

Tags: abrasion loss,abrasion rate,elongation at break,EP rubber conveyor belt,QUALITY,Rubber conveyor belt,Steel cord conveyor belt,TENSILE STRENGTH,testing