How to conduct conveyor belt troughing test

This standard specifies the test method and specifications for the performance of conveyor belts transitioning from flat to troughed, to achieve good contact with troughed carrying idler sets (referred to as troughability) during use.

This test should be conducted for conveyor belts used on conveyors equipped with troughed carrying idler sets. If the belt does not exhibit good troughability, it may result in poor stability during use, leading to lateral movement and potential damage to the conveyor belt.

Definitions:

1.1 Troughability (T): In the conveyor belt troughability test, the ratio of the maximum deflection F of the test sample to the belt’s flat width L within a specified time.

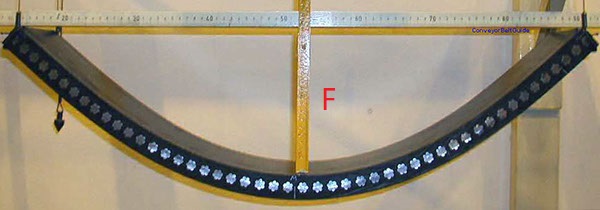

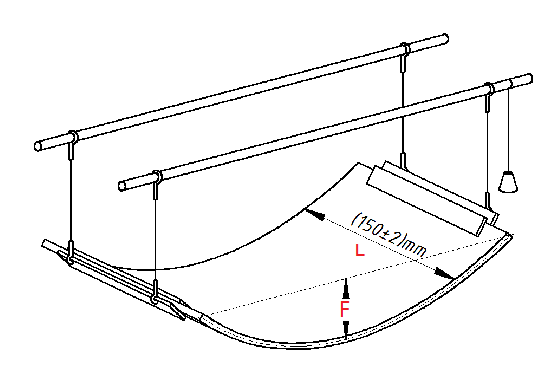

1.2 Maximum Deflection (F): In the conveyor belt troughability test, the vertical distance between the central points on the upper and lower surfaces of the test sample at the ends to the lowest point of curvature on the upper and lower surfaces (see Figure 1).

1.3 Side Idler Inclination: The angle between the side idler and the horizontal direction in the troughed carrying idler set composed of a central idler and two side idlers.

Test Principle: A segment of the full-width conveyor belt is taken as the test sample and suspended at both ends, allowing it to hang freely under its own gravity. The maximum deflection is measured within a specified time, and the troughability is calculated.

2.Test Apparatus: The test apparatus consists of the following components (see Figure 2):

2.1 Two rigid bars supported on supports, which should meet the following requirements:

a. The distance between the two support points of each bar is greater than the width of the test conveyor belt.

b. The distance between the two bars is equal to the distance between two points on the clamps connected to the suspension line.

2.2 Two clamps used to hold the test sample at both ends, which should meet the following requirements:

a. Each end has a part for connection to the suspension line in a way that allows free rotation.

b. The structure should ensure that the clamps themselves have negligible unbalance forces after suspension and negligible friction during rotation, i.e., they will not affect the sample’s deflection.

c. The clamping width of the sample should be at least 140mm.

d. Their rigidity should ensure that the sample does not bend in the width direction during the test (i.e., the length direction of the belt).

2.3 Four suspension wires made of the same material, which should meet the following requirements:

a. Their elongation under the gravity of the test sample and the clamps is negligible.

b. The connection between the suspension wires and the horizontal bars should allow movement of the contact points along the length of the bars.

c. Their length is approximately 500mm, and they should maintain the horizontal alignment of the axes of rotation of the two clamps.

2.4 Tools for measuring sample deflection.

2.5 A plumb bob for indicating the vertical direction of the suspension line.

3. Conveyor Belt Test Samples:

3.1 The shape, dimensions, and quantity of test samples are as follows:

a. Shape: Rectangular on all sides.

b. Length (across the belt width): The flat width of the belt.

c. Width (along the belt length): 150±1mm.

d. Thickness: The full thickness of the belt.

e. Quantity: 2 samples.

3.2 The samples should be cut from the belt at least 5 days after the belt is manufactured.

3.3 The two samples should be taken from positions on the belt as far apart as possible.

3.4 The samples should be placed horizontally in a 23±2°C environment for at least 24 hours before testing.

4. Test Procedure and Key Points:

4.1 The test should be conducted in an environment with a temperature of 23±2 degrees Celsius.

4.2 Measure the flat width of the conveyor belt (i.e., the length of the test sample).

4.3 Clamp the ends of the conveyor belt test sample in the clamps of the two holders, ensuring that the carrying surface of the conveyor belt faces upward. The clamping should be symmetrical, with equal clamping depths, with the smaller depth being 15mm.

4.4 Allow the conveyor belt test sample to hang freely under its own gravity. Continuously adjust the direction of the suspension line to be vertical. When the test sample has hung freely for 5 minutes, measure the maximum deflection of the sample.

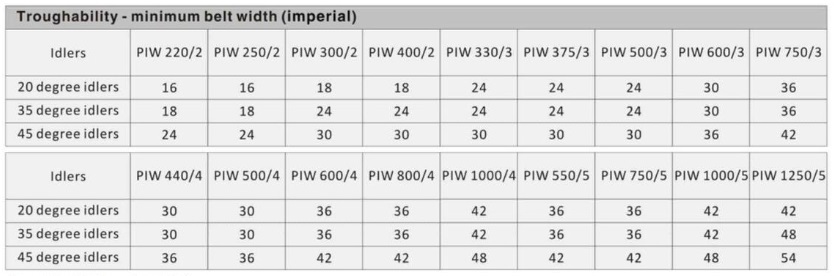

Adviced conveyor belt width(Min.) for PIW conveyor belt:

SUNGDA CONVEYOR BELT CO.,LTD.

Tags: PIW,QUALITY,Rubber conveyor belt,test,troughability