EP conveyor belt layer is the more the better?

We found that many customers tend to choose conveyor belts with more EP fabric layers when they select EP conveyor belts, because they all think that such conveyor belts will be better to use, but the truth is true. ?

In fact, this is not the case. The use of the conveyor belt is determined by the size of the conveyor pulley and the amount or weight of the material being conveyed, as well as the use environment of the conveyor belt and other factors, so the suitable one is better.

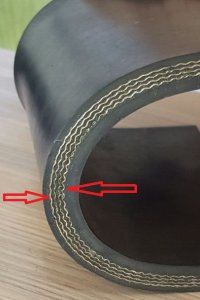

When the number of layers of the EP conveyor belt is too much, the overall flexibility of the lifting belt is reduced. The carcass fiber is in a tensioned state. When passing through the conveyor pulley, the flexural tension on the fiber is increased, resulting in fiber breakage. Although the lifting belt had sufficient tear strength, it did not take long for it to cross. Therefore, when selecting the model, it is not better to have more EP layers. When the strength is enough, it is not necessary to add more EP fabric layers. In order to improve the flexion between the layers, the thickness of the skim rubber can be increased, so that the use of the EP layered conveyor belt life can be improved.

Therefore, it is not to say that the more EP layers, the better, the more it will affect the overall performance of the EP layered conveyor belt, so it is necessary to distinguish the quality of the EP layer rather than the quantity when purchasing.

The EP layered conveyor belt must have sufficient tensile strength and elastic modulus to achieve the required transmission power for conveying the material within the required distance and allow the operating elongation resulting from lower loading under load. The EP layered conveyor belt should have good load support and sufficient width to meet the type and volume required when transporting materials. It must have dimensional stability to make the conveyor belt run smoothly. The covering rubber on the bearing surface must withstand the load impact of the bearing object, and once it can help restore elasticity, the covering rubber can have sufficient friction with the conveyor pulley during transmission.

Tags: conveyor belt layer,EP conveyor belt