DIN-X,DIN-W,DIN-Y and DIN-Z Rubber Conveyor Belt –SUNGDA

In the detailed specifications of rubber conveyor belts, we often see some abbreviations such as DIN-W, DIN-X, DIN-K and DIN-Y, and even some customers directly use Grade X, Grade Y to express. So what do these abbreviations represent?

Let me first understand the origin of “DIN”, the DIN standard was established by the “German Institute for Standardization”, the letter “DIN” stands for “Deutsches Institut für Normung”, they formulate specifications and standards as a service to the German industry. They are a highly respected non-profit organization, it has been based in Berlin since 1917, many DIN standards have been converted to EN or even ISO standards.

In Europe and many parts of the world, DIN standards are more generally recognized and accepted, especially in the case of abrasion resistant conveyor belt.At present, most of the DIN conveyor belt standards followed all over the world are based on the DIN22102 standard, It is mainly used to indicate the three important indicators of conveyor belt cover rubber, namely “Tensile Strength”, “Elongation at Break” and “Abrasion Loss”.

The following table shows the four most commonly used DIN overlay specifications, namely DIN-X, DIN-W, DIN-Y and DIN-Z:

So what are the specific meanings and experimental methods of these three indicators?

1.Tensile Strength

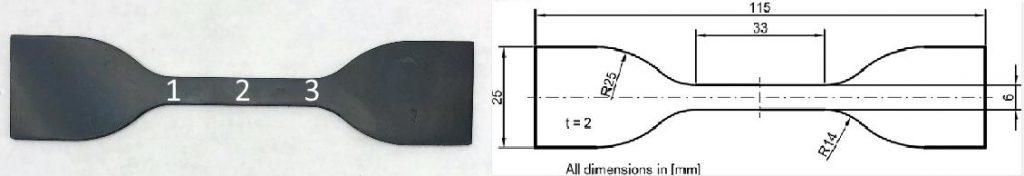

Tensile strength is usually measured as the amount of force in pounds per square inch (psi) or megapascals (MPa) required to pull a specimen to the point of material failure. This test is accomplished by placing a dumbbell shaped specimen into the grips, or jaws, of a tensometer. The tensometer pulls the grips apart steadily until the dumbbell breaks. The force at material rupture is known as ultimate tensile strength, which is commonly shortened to tensile strength or tensile.

Rubber Test Sample:

Tensile Strength Test Machine:

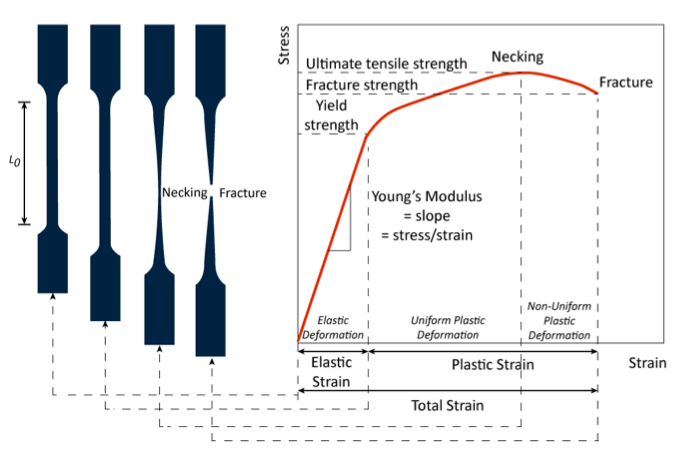

2.Elongation at Break

Elongation is measured by applying tensile force, or stretching the material in the same manner as described previously, and determining the change in length from original. Elongation is expressed as a percentage of the original length. Ultimate elongation is the percentage change in length from original to rupture.

Elongation Test Machine:

Elongation at break test change graph:

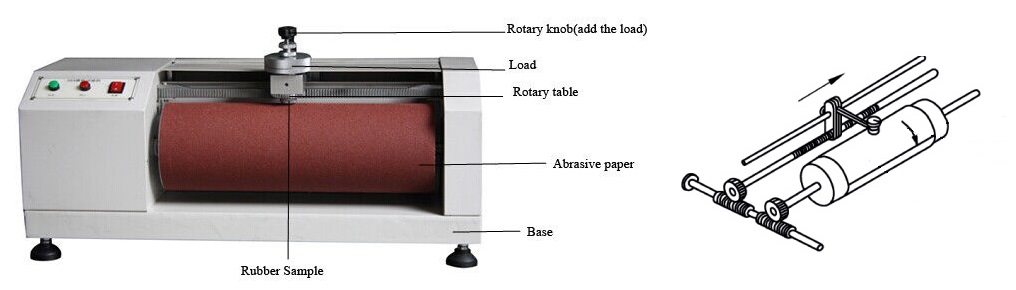

3. Abrasion Loss Rate

Abrasion rate is also called abrasion loss or abrasion reduction, simply, it is to measure the surface loss of the conveyor belt cover rubber during the running friction process through special testing equipment. The standard of our conveyor belt stipulates that the DIN abrasion meter is used for testing, and the abrasion unit is mm³.

4. Fire (Flame) resistance capability

Fire and flame resistant rubber conveyor belt for overground applications according to DIN-K

Conveyor belt, intended for transport of inflammable and explosive materials. Suitable for coal loading and transportations, coal dust, steel mill and foundries, food industries (powders, grain, sugar…), wood industries, aluminum, paper, chemical and fertilizer industries.

Conveyor belt meets the following requirements: resistance to burning with covers, antistatic, drum friction test.

Tensile strength, elongation at break and abrasion loss in different DIN standards:

| Cover Grade | Country | Applicable Standards | Min.Tensile Strength(Mpa) | Min.Elongation at Break(%) | Max.Abrasion Loss(mm3) |

| DIN-Z | Germany | DIN22102 | 15 | 350 | 250 |

| DIN-Y | Germany | DIN22102 | 20 | 400 | 150 |

| DIN-X | Germany | DIN22102 | 25 | 450 | 120 |

| DIN-W | Germany | DIN22102 | 18 | 400 | 90 |

What is the Safety Factor of Conveyor Belt?

Comparison of RMA and DIN Standard for Conveyor Belts

EP Conveyor Belt Layer is the More, the Better?

Max.5000 mm Width Belt for Horizontal Vacuum Belt Filter

Other DIN standard and ISO standard:

Sungda Conveyor Belt Co.,Ltd

We also supply conveyor idler roller, pulley and conveyor bracket, please log to our branch company official website www.conveyoroller.com or click below picture for idler roller producing video.

SUNGDA Regular Customer:

Tags: abrasion loss,conveyor belt standard,DIN-K,DIN-W,DIN-X,DIN-Y,DIN-Z,DIN22102,elongation at break,fire resistant conveyor belt,steel mill,TENSILE STRENGTH