What is the Meaning of 12Mpa,15Mpa,18Mpa,24Mpa in Conveyor Belt Specification?

When describing the specifications and models of rubber conveyor belts, we often encounter 12Mpa, 15Mpa, 18Mpa, 20Mpa and 24Mpa, etc. What physical properties do these values represent?

The Mpa in the conveyor belt refers to the ultimate ability of the rubber cover to resist tensile failure, also called “Tensile Strength”, it refers to the load on the unit section when the test rubber piece is stretched to break, so it is also called the breaking strength, the unit is megapascal (Mpa), the tensile strength index is generally used as the physical and mechanical performance standard of the rubber cover(both for top and bottom cover) of the conveyor belt, and together with the elongation at break (%) and abrasion loss (mm3), it is called the three main performance indicators of the rubber cover of the conveyor belt

However, due to the traditional and customary usage variations between metric and imperial systems, as well as among different countries and regions, there can be inconsistencies in the units used to describe conveyor belt tensile strength. This necessitates an understanding of some basic unit conversion relationships. Common pressure units in the conveyor belt industry include megapascals (MPa), pounds per square inch (psi), kilograms per square centimeter (kg/cm²), bars, and atmospheres (atm). The conversion relationships between these units are:

1 megapascal (MPa)=145 pounds/inch2 (psi)=10.2 kilograms/cm2 (kg/cm2)=10 bar (bar)=9.8 atmospheric pressure (at m)=1N/mm2

The higher the Mpa rating, means the stronger the strength of the conveyor belt cover, the higher the tensile strength, and the longer the service life of the conveyor belt cover under the same transportation environment.

So how to test the tensile strength of conveyor belt cover?

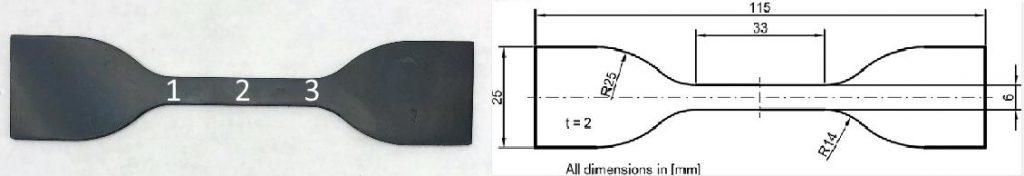

This test is accomplished by placing a dumbbell shaped specimen into the grips, or jaws, of a tensometer. The tensometer pulls the grips apart steadily until the dumbbell breaks. The force at material rupture is known as ultimate tensile strength, which is commonly shortened to tensile strength or tensile.

Rubber Cover Test Sample:

Tensile Strength Test Machine:

Rubber Piece Test Processing:

Different countries have their own different requirements for tensile strength, at present, almost all conveyor belt manufacturers in the world market follow several internationally recognized rubber cover strength grade systems. Most countries follow the German DIN22102 class standard. Of course, there are also regional grading standards. For example, most countries in the United States are used to following the RMA grading standard. The country also has its own grading standards covering standards such as GB/T7984 in China, AS1332 in Australia, JISK6322 in Japan, BS-490 in the UK and SANS-1173 in South Africa.

| Cover Grade | Country | Applicable Standards | Min.Tensile Strength(Mpa) | Min.Elongation at Break(%) | Max.Abrasion Loss(mm3) |

| DIN-Z | Germany | DIN22102 | 15 | 350 | 250 |

| DIN-Y | Germany | DIN22102 | 20 | 400 | 150 |

| DIN-X | Germany | DIN22102 | 25 | 450 | 120 |

| DIN-W | Germany | DIN22102 | 18 | 400 | 90 |

| RMA-I | U.S.A | RMA | 17 | 400 | 150 |

| RMA-II | U.S.A | RMA | 14 | 400 | 200 |

| ARPM RMA-I | U.S.A | ARPM | 17 | 400 | 125 |

| ARPM RMA-II | U.S.A | ARPM | 14 | 400 | 175 |

| ISO-L | International | ISO -10247 | 15 | 350 | 200 |

| ISO-H | International | ISO -10247 | 24 | 450 | 120 |

| ISO-D | International | ISO -10247 | 18 | 400 | 100 |

| AS-N | Australian | AS -1332 | 17 | 400 | 200 |

| AS-M | Australian | AS -1332 | 24 | 450 | 125 |

| AS-A | Australian | AS -1332 | 17 | 400 | 70 |

| SANS-N | South Africa | SANS-1173 | 17 | 400 | 150 |

| SANS-M | South Africa | SANS-1173 | 25 | 450 | 120 |

| SANS-A | South Africa | SANS-1173 | 18 | 400 | 70 |

| BS-M | UK | BS-490 | 24 | 450 | 120 |

| BS-N | UK | BS-490 | 17 | 400 | 200 |

| IS-N-17 | India | IS 1891 | 17 | 400 | 200 |

| IS-M-24 | India | IS 1891 | 24 | 450 | 150 |

| JIS-G | Japan | JIS-K 6332 | 14 | 400 | 250 |

| JIS-L | Japan | JIS-K 6332 | 15 | 350 | 200 |

| JIS-D | Japan | JIS-K 6332 | 18 | 400 | 100 |

| JIS-H | Japan | JIS-K 6332 | 24 | 450 | 120 |

| GB-H | China | GB/T 7984 | 24 | 450 | 120 |

| GB-D | China | GB/T 7984 | 18 | 400 | 100 |

| GB-L | China | GB/T 7984 | 15 | 350 | 200 |

Sungda Conveyor Belt Co.,Ltd

Tags: 12MPA CONVEYOR BELT,15MPA CONVEYOR BELT,17MPA CONVEYOR BELT,18MPA,20MPA,24MPA,25MPA,CONVEYOR BELT MPA,conveyor belt specification,DIN-W,DIN-Y,DIN-Z,DIN22102,EP conveyor belt,RMA CONVEYOR BELT,TENSILE STRENGTH