RMA-I & RMA-II Rubber Conveyor Belts–SUNGDA

With the rapid development and integration of the world economy, conveyor belt products have played a very important role, especially in the field of bulk material transportation, mining and energy. Among all the technical standards of conveyor belts, the most commonly used ones are also the most important specification is the technical standard of the rubber cover.

All conveyor belts follow several internationally accepted rubber cover rating systems, most countries follow the German DIN22102 Grade standard, and of course there are regional grade standards, for example, American countries are accustomed to following the RMA grade standard, other countries also have their own overlay standards, such as China’s GB/T7984, Australia’s AS1332, Japan’s JISK6322, the United Kingdom’s BS-490 and South Africa’s SANS-1173, etc.

These standards are designed to provide end users with information on different applications refer to what grades are used in these ratings. These ratings specify different laboratory test standards, but do not provide any performance guarantees in specific applications.

In the selection of conveyor belts and international trade business, understand these standards and how to convert each other among these standards is very important, let’s take a look at the RMA standard:

RMA is the abbreviation of “Rubber Manufacturers Association”in United States, it has established two standard grades of rubber conveyor belt cover: RMA-I and RMA-II, the RMA-I (17Mpa) grade meets the higher requirements of rubber stretch and elongation, and usually shows higher cutting and scratch resistance than the RMA-II (14Mpa). It should be noted that grades do not necessarily indicate overall wear resistance. The International Organization for Standardization (ISO) also established a grading system under ISO 10247.

This standard includes:

Category H (Severe Cut and Gouge Service, Category)

Category D (Severe Abrasion Service)

Category L (Moderate Service).

Among them, category H is roughly comparable to RMA Grade I; categories D and L approximate RMA Grade II belting.

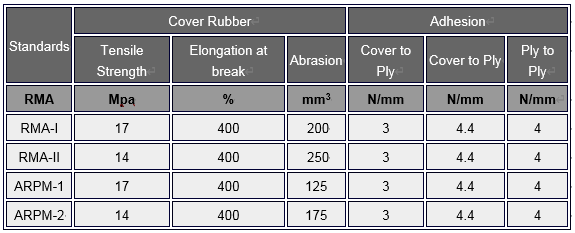

ARPM (Association for Rubber Products Manufacturers), a successor of RMA. Published their conveyor belt handbook in 2011, determining grade 1 with tensile strength of 17 MPa, elongation at break of 400 % and volume loss of 125 mm³, and grade 1 with tensile strength of 14 MPa, elongation at break of 400 % and volume loss of 175 mm³, This means that the standards established by ARPM have higher requirements for abrasion rate.

Performance characteristics and application of RMA-I rubber cover

- 1. RMA Grade I rubber compound

- 2. Superior resistance to cutting, gouging and tearing from the impact of large materials

- 3. High abrasion resistance and excellent low temperature flexibility

- 4. Recommended for service with all kinds of hard, sharp ores, quartz, trap rock, riprap, granite, glass cullet, scrap metal, ballast, etc.

Performance characteristics and application of RMA-II rubber cover

- 1. RMA Grade II rubber compound

- 2. Durable and long-lasting in abrasive applications

- 3. Resistant to cuts and gouges, flexible at lower temperatures

- 4. Ideal for conveying sand and gravel, lime stone, crushed rock, slag, coke, coal, cement rock, phosphate rock and most material weighing between 50 and 120 Ibs. per cubic foot

Main Technical Parameter for RMA-I and RMA-II:

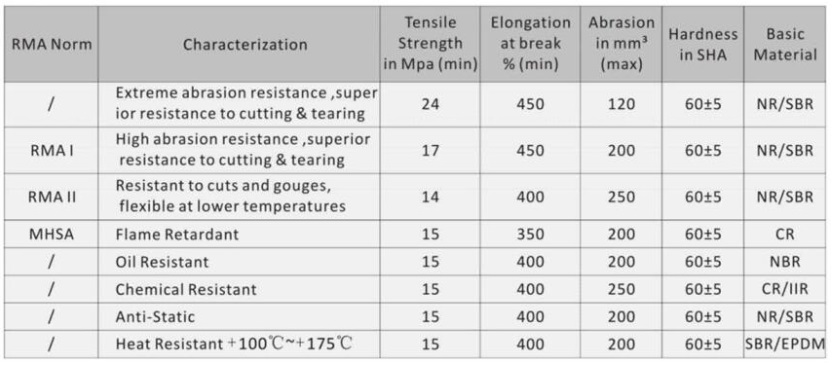

There are also some conveyor belts used in special environments, such as the transportation of high-temperature materials, chemically corrosive materials, underground mines or oily materials or chemicals. Such environments have special requirements on the chemical properties of rubber, such as heat resistance, oil resistance and flame retardancy, etc., so it is best to understand the operating conditions first, and then consult a reputable supplier before choosing the conveyor belt category.

What is the Safety Factor of Conveyor Belt?

Comparison of RMA and DIN Standard for Conveyor Belts

EP Conveyor Belt Layer is the More, the Better?

Max.5000 mm Width Belt for Horizontal Vacuum Belt Filter

Technical Specification for Other Rubber Grade:

The following table is currently the main internationally popular conveyor belt implementation standards:

| Cover Grade | Country | Applicable Standards | Min.Tensile Strength(Mpa) | Min.Elongation at Break(%) | Max.Abrasion Loss(mm3) |

| DIN-Z | Germany | DIN22102 | 15 | 350 | 250 |

| DIN-Y | Germany | DIN22102 | 20 | 400 | 150 |

| DIN-X | Germany | DIN22102 | 25 | 450 | 120 |

| DIN-W | Germany | DIN22102 | 18 | 400 | 90 |

| RMA-I | U.S.A | RMA | 17 | 400 | 150 |

| RMA-II | U.S.A | RMA | 14 | 400 | 200 |

| ARPM RMA-I | U.S.A | ARPM | 17 | 400 | 125 |

| ARPM RMA-II | U.S.A | ARPM | 14 | 400 | 175 |

| ISO-L | International | ISO -10247 | 15 | 350 | 200 |

| ISO-H | International | ISO -10247 | 24 | 450 | 120 |

| ISO-D | International | ISO -10247 | 18 | 400 | 100 |

| AS-N | Australian | AS -1332 | 17 | 400 | 200 |

| AS-M | Australian | AS -1332 | 24 | 450 | 125 |

| AS-A | Australian | AS -1332 | 17 | 400 | 70 |

| SANS-N | South Africa | SANS-1173 | 17 | 400 | 150 |

| SANS-M | South Africa | SANS-1173 | 25 | 450 | 120 |

| SANS-A | South Africa | SANS-1173 | 18 | 400 | 70 |

| BS-M | UK | BS-490 | 24 | 450 | 120 |

| BS-N | UK | BS-490 | 17 | 400 | 200 |

| IS-N-17 | India | IS 1891 | 17 | 400 | 200 |

| IS-M-24 | India | IS 1891 | 24 | 450 | 150 |

| JIS-G | Japan | JIS-K 6332 | 14 | 400 | 250 |

| JIS-L | Japan | JIS-K 6332 | 15 | 350 | 200 |

| JIS-D | Japan | JIS-K 6332 | 18 | 400 | 100 |

| JIS-H | Japan | JIS-K 6332 | 24 | 450 | 120 |

| GB-H | China | GB/T 7984 | 24 | 450 | 120 |

| GB-D | China | GB/T 7984 | 18 | 400 | 100 |

| GB-L | China | GB/T 7984 | 15 | 350 | 200 |

The Top 5 Rubber Conveyor Belt Manufactures In China 2022

What are the advantages of EP conveyor belts compared to ordinary conveyors?

What is PIW in the EP conveyor belt and how to convert it into N/mm?

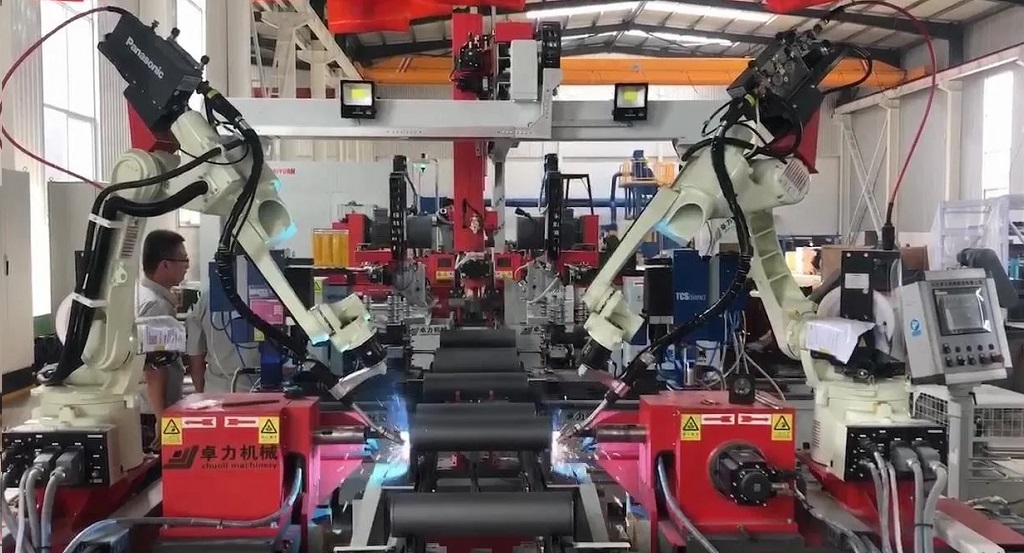

SUNGDA Conveyor Belt Workshop:

How to choose crushing plant conveyor belt for 100 ~ 1000T/H scale?

EP conveyor belt layer is the more, the better?

How to choose the cover thickness of conveyor belt?

We also supply conveyor idler roller, pulley and conveyor bracket, please log to our branch company official website www.conveyoroller.com or click below picture for idler roller producing video.

Tags: AMERICAN,ARPM,conveyor belt standard,RMA CONVEYOR BELT,RMA-I,RMA-II