Chevron/Pattern Rubber Conveyor Belt

Generally, the transportation angle of the flat conveyor belt is below 20°, otherwise the material will slide or roll off. The appearance of the chevron conveyor belt solves this problem very well, the chevron profile conveyor belt is also called pattern conveyor belt or cleat top conveyor belt. It refers to the pattern for the chevron conveyor belt, the function of the pattern is to prevent the material from sliding down and play the role of friction, the conveying angle of the chevron pattern conveyor belt is generally greater than 22 degrees, which can effectively help the materials to be lifted to the specified height, it is a patterned conveyor belt with a wide range of applications, and uses high-quality patterned conveyor belts in various industries.

1. Application: Chevron conveyor belt is precisely suited for conveying bagged or bulky and loose materials on sloping surface at angles of less than 40°. It is applicable in many industrial applications including coal, minerals, ore and solid duty scrap metal. This anti-slip chevron conveyor belt has top cover & cleats are vulcanized integrally. The angle, pitch and pattern of cleat are designed elaborately.

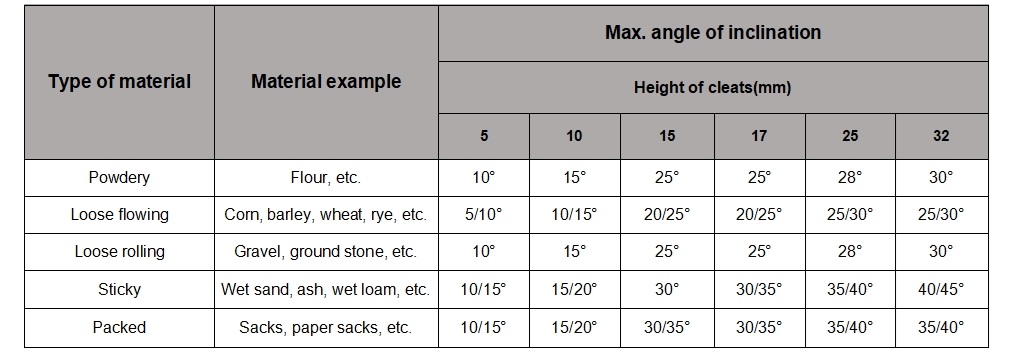

The guide to choose cleat height of chevron belt according to material and angle:

2. Features:

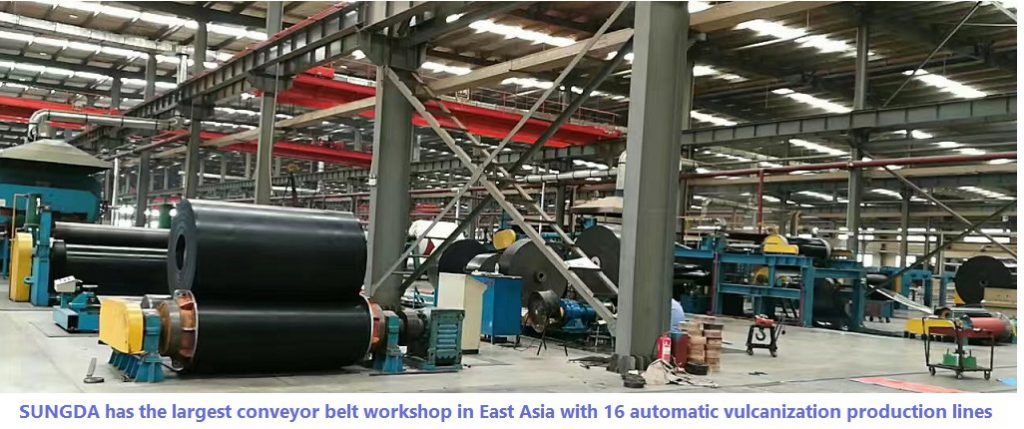

1. Sungda chevron patterns are moulded in one continuous vulcanised production process together with the base belt. This creates a integral, homogeneous belt structure that is far stronger than belts that have the chevron patterns attached separately.

2. Chevron molds are made of high-precision steel, which is beautiful and highly wear-resistant, and cleats and top cover rubber are vulcanized integrally;

3. Cleat pattern, angle and pitch are designed elaborately.

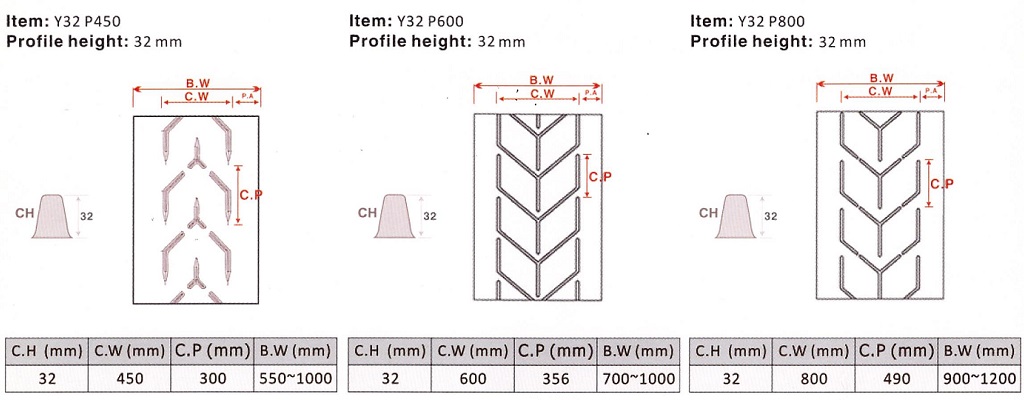

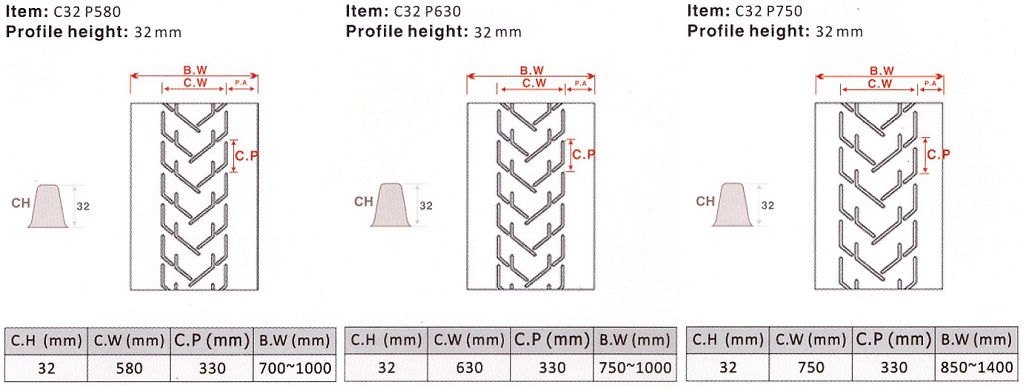

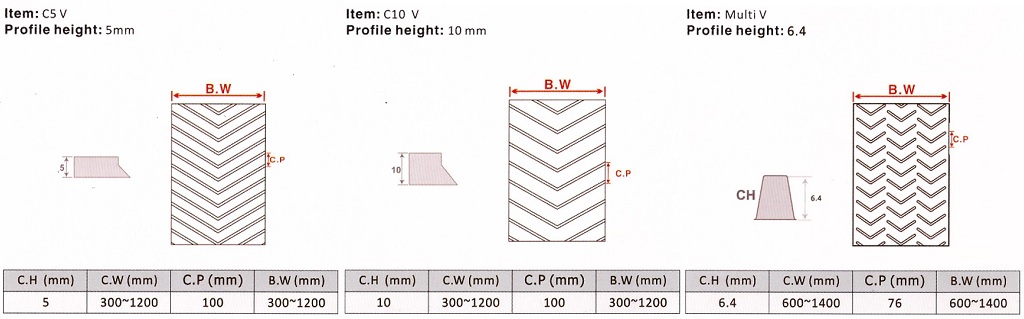

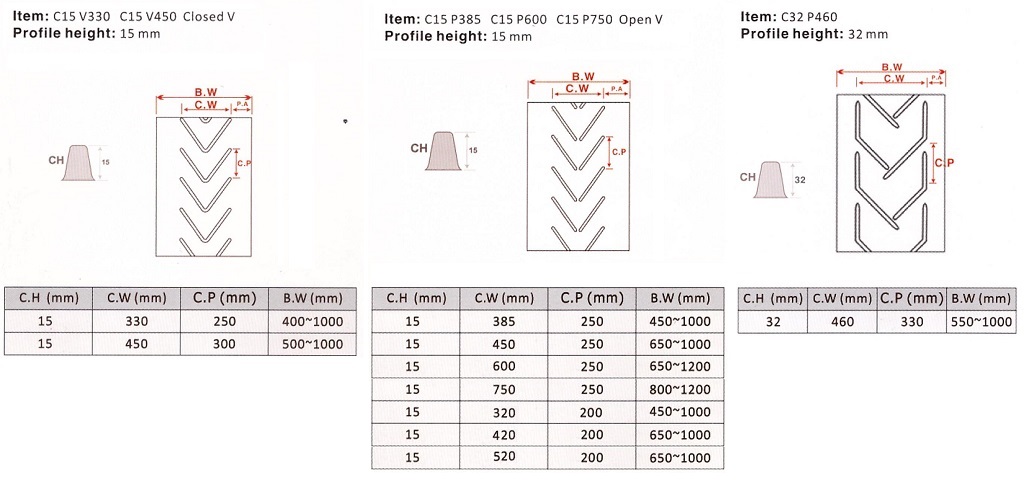

4.Chevron Patterns styles have:

“C” series: C5V/Multi V/C15/C17/C25/C32

“S”series: S15/S25

“Y”series: Y32

Special Type: Fish-bone/Multi “V”

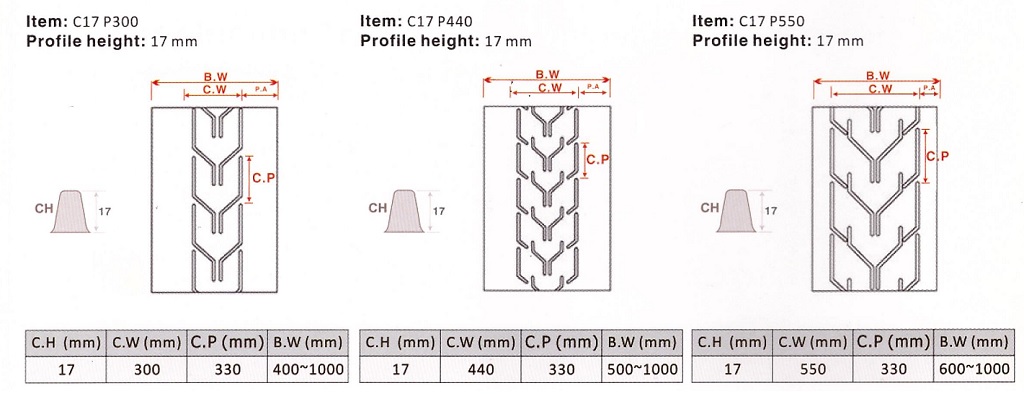

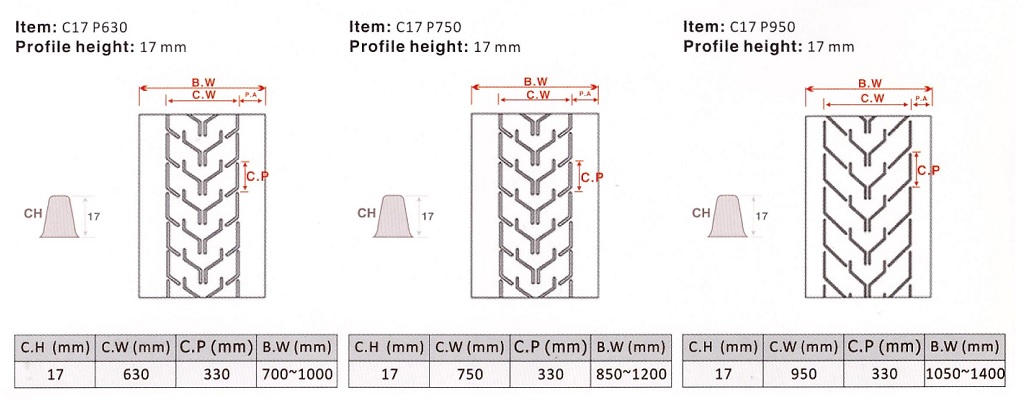

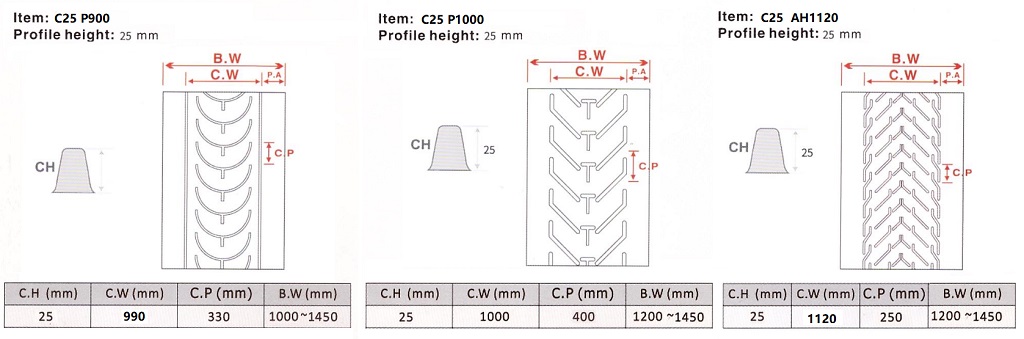

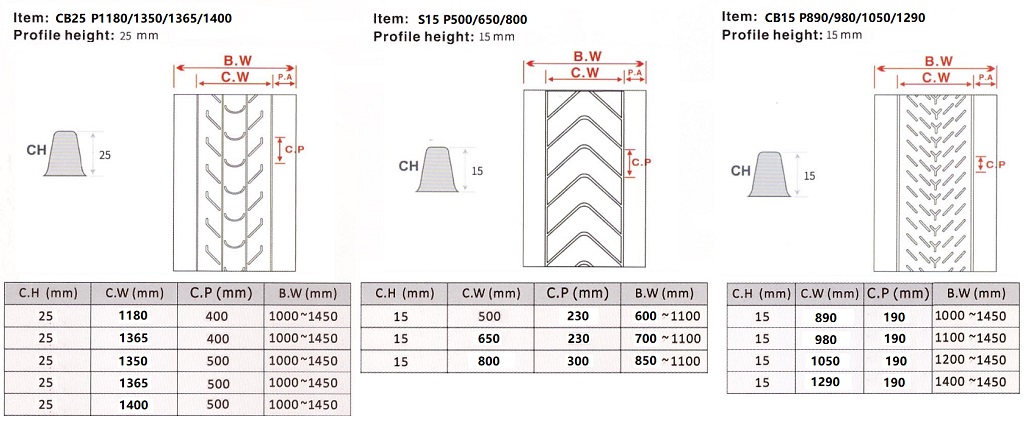

The following are some commonly used chevron patterns, cleat size and corresponding conveyor belt width:

Our featured chevron belt is 3ply/4ply range of DIN grade C15 & C25 chevron cleat rubber conveyor belt: 3P450C15, 3P600C15, 3P650C15, 3P/4P750C15, 3P/4P800C15, 3P/4P900C15, 3P/4P1200C15, 3P/4P900C25, 3P900C25 & 3P1200C25 is produced in both a 15 mm or 25 mm high chevron V cleat in varying pitch centers and pattern width dependent on the actual belt widths, the applications of these type chevron type are grains, corn, barley, wheat, gravel, ground stone and sacks delivery.

The range of chevron V6, C6, C15 & C25 chevron belts are suitable for over roller incline conveying applications and in particular mobile road scalpers, cold planers & crushers, spreaders, batching plants & tub grinders. Our cleat rubber conveyor belt is manufactured with an EP (polyester/nylon) carcass that provides high strength, low stretch, excellent trough ability & good impact resistance.

Comparison of RMA and DIN Standard for Conveyor Belts

The Top 5 Rubber Conveyor Belt Manufactures in China 2023-2024(with website & contact info)

What is the difference between PSI and Mpa in conveyor belts and how to convert them to each other?

EP Conveyor Belt Layer is the More, the Better?

Sungda Conveyor Belt Co.,Ltd.

- What are the Basic Indicators that Determine the Quality of Conveyor Belts?

- What is Conveyor Belt Tensile Strength and Elongation at Break?

- What Are the Key Properties of T1, T2, T3, T4 Heat-Resistant Conveyor Belts?

- What’s “kg/cm²” in Conveyor Belt and How Convert it into other Units?

- How to Calculate PIW of Conveyor Belt?

Our Regular Customers:

Tags: Advantages and features of chevron conveyor belts,Anti-slip performance of chevron conveyor belts,Applications and industries of chevron conveyor belt,C15,C17,C25,C32,Chemical resistance of chevron conveyor belts,Chevron angle and height of chevron conveyor belts,Chevron profile conveyor belt,Chevron Rubber Conveyor Belt,Cleated Top conveyor belt,Comparison of chevron conveyor belts with other types,FISHBONE,flour lime conveyor belt,grains corn barley wheat conveyor belt,gravel conveyor belt,ground stone conveyor belt,guide,high angle conveyor belt,incline conveyor belt,Installation and maintenance guide for chevron conveyor belts,Manufacturers and suppliers of chevron conveyor belts,Oil resistance of chevron conveyor belts,Over 22º conveyor belt,pattern conveyor belt,pitched conveyor belt,Pricing and cost of chevron conveyor belts,Profiled conveyor belt,S15,S25,sacks conveyor belt,SPECIAL CONVEYOR BELT,specification,Steep-Incline conveyor belt,Suitable material types for chevron conveyor belts,U-shape conveyor belt,V type conveyor belt,Y32