EP Rubber Conveyor Belt

General Introduction:

EP rubber conveyor belt is widely used by the mining and processing industries for transporting bulk or lumpy materials such as quarrying, ore, coke, aggregates, crops, sand, clinker, chemicals, construction materials, etc.

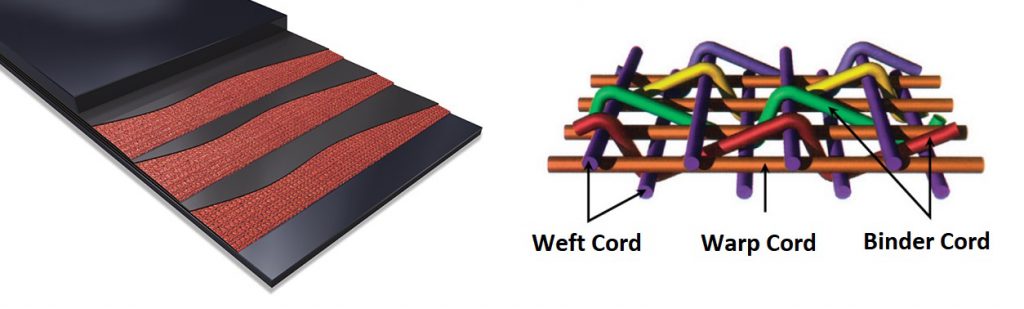

The EP is short for Polyester fabric, which includes polyester toward longitudinal(warp) and polyamide for latitude(weft), EP fabric plies are sandwiched between rubber skim coats for adhesion and load support. Bottom and top cover compounds are added for maximum protection of the belt carcass. The EP conveyor belt consisting of two to six EP fabric plies, EP rubber conveyor belt has the same merit as Nylon conveyor belt, in addition, EP fabric has the advantages of:

A.Lower longitudinal elongation.

B.Full resistance to mildew, moisture and rotting.

C.Good flexibility and trough ability.

D.Short take-up lengths.

E.Suitable for middle and long-distance transportation of higher load and speed.

The Top 5 Rubber Conveyor Belt Manufactures In China 2023

How to choose crushing plant conveyor belt for 100 ~ 1000T/H scale?

EP conveyor belt layer is the more the better?

How to choose the cover thickness of conveyor belt?

EP fabric also has excellent compatibility with other rubbers, so it can be combined with any type of cover grade to make it a perfect match for almost any application. This allows EP conveyor belt to convey basically any type of product in any environment, from fine powders to large lumps, from dry to greasy materials, from extremely cold to very hot conditions.

The common ep conveyor belt type could be:

2-ply belts: 315/2 400/2 500/2 630/2 800/2

3-ply belts: 500/3 630/3 800/3 1000/3 1250/3

4-ply belts: 630/4 800/4 1000/4 1250/4 1600/4

5-ply belts: 800/5 1000/5 1250/5 1600/5 2000/5

EP Fabric Technical Specification:

| Test Item | EP100 | EP125 | EP150 | EP200 | EP250 | EP300 | EP350 | EP400 | EP500 | |||||||||

| warp | weft | warp | weft | warp | weft | warp | weft | warp | weft | warp | weft | warp | weft | warp | weft | warp | weft | |

| Breaking strength (N/mm) | ≥100 | ≥55 | ≥125 | ≥65 | ≥150 | ≥75 | ≥200 | ≥78 | ≥250 | ≥80 | ≥300 | ≥80 | ≥350 | ≥75 | ≥400 | ≥90 | ≥500 | ≥105 |

| Breaking elongation (%) | ≥14.0 | ≤45.0 | ≥14.0 | ≤45.0 | ≥14.0 | ≤45.0 | ≥14.0 | ≤45.0 | ≥14.0 | ≤45.0 | ≥14.0 | ≤45.0 | ≥14.0 | ≤45.0 | ≥14.0 | ≤45.0 | ≥14.0 | ≤45.0 |

| Elongation at 10% load (%) | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤2.0 | ≤2.0 | |||||||||

| Heat shrinkage (150℃, 30Min.) | ≤5.0 | ≤1.0 | ≤5.0 | ≤1.0 | ≤5.0 | ≤1.0 | ≤5.0 | ≤1.0 | ≤6.0 | ≤1.0 | ≤6.0 | ≤1.0 | ≤6.0 | ≤1.0 | ≤6.0 | ≤1.0 | ≤6.0 | ≤1.0 |

| Adhesion (N/2.5cm) | ≥196.0 | ≥196.0 | ≥196.0 | ≥196.0 | ≥196.0 | ≥196.0 | ≥196.0 | ≥196.0 | ≥196.0 | |||||||||

| Weight (G/m²) | 370±30 | 430±30 | 520±30 | 610±40 | 780±40 | 860±40 | 980±40 | 1180±50 | 1320±50 | |||||||||

| Thickness (mm) | 0.53±0.06 | 0.62±0.06 | 0.70 ± 0.06 | 0.85±0.09 | 1.00±0.10 | 1.15±0.10 | 1.20±0.10 | 1.50±0.12 | 1.70±0.14 | |||||||||

SUNGDA EP rubber conveyor belt products have five types according to coating difference: Anti-split type, Anti-abrasion type, common type,acid-alkali resistant type, and heat-resistant conveyor belt type.

SUNGDA cover rubber grade for general purpose:

DIN22102 Standard:

| Standard | DIN-W | DIN-X | DIN-Y | DIN-Z | ||

| Tensile test | Before Aging | Tensile Strength (Mpa) | >18 | >25 | >20 | >15 |

| Elongation(%) | >400 | >450 | >400 | >350 | ||

| After Aging | Change rate of TS(%) | ±25 | ±25 | ±25 | ±25 | |

| Change rate of EL(%) | ±25 | ±25 | ±25 | ±25 | ||

| Abrasion test(mm³) | <90 | <120 | <150 | <250 | ||

AS-RMA Standard

| Standard | AS-N | AS-M | AS-A | RMA-I | RMA-II | ||

| Tensile test | Before Aging | Tensile Strength (Mpa) | >17 | >24 | >17 | >17 | >14 |

| Elongation(%) | >400 | >450 | >400 | >450 | >400 | ||

| After Aging | Change rate of TS(%) | ±20 | ±20 | ±20 | ±25 | ±25 | |

| Change rate of EL(%) | ±20 | ±20 | ±20 | ±25 | ±25 | ||

| Abrasion test(mm³) | <200 | <125 | <70 | <150 | <200 | ||

Muti-ply EP Fabric Grade (Tensile Strength kg/cm, PIW):

| Fabric/Ply | 3P | 4P | 5P | 6P | ||||

| kg/cm | PIW | kg/cm | PIW | kg/cm | PIW | kg/cm | PIW | |

| EP-100 | 300 | 1680 | 400 | 2240 | 500 | 2800 | 600 | 3360 |

| EP-125 | 375 | 2100 | 500 | 2800 | 625 | 3500 | 750 | 4200 |

| EP-150 | 450 | 2520 | 600 | 3360 | 750 | 4200 | 900 | 5040 |

| EP-200 | 600 | 3360 | 800 | 4480 | 1000 | 5600 | 1200 | 6720 |

| EP-250 | 750 | 4200 | 1000 | 5600 | 1250 | 7000 | 1500 | 8400 |

| EP-300 | 900 | 5040 | 1200 | 6720 | 1500 | 8400 | 1800 | 10080 |

| EP-350 | 1050 | 5880 | 1400 | 7840 | 1750 | 9800 | 2100 | 11760 |

* PIW=Pounds Per Inch Of Belt Width

If you are from the U.S or Europe, you may need to convert between PIW with N/mm, please click here to see how to convert it.

SUNGDA Conveyor Belt Workshop:

SUNGDA Regular Customer around the world:

For more information please log on www.sungda.com or email us to overseas@sungda.com

Related Ep conveyor belt article:

-

What are the advantages of EP conveyor belts compared to ordinary conveyors?

-

How does the bending of EP fabric affect the working life of the conveyor belt?

-

What is PIW in the EP conveyor belt and how to convert it into N/mm

-

How to identify the quality of the EP conveyor belt in one minute?

| Cover Grade | Country | Applicable Standards | Min.Tensile Strength(Mpa) | Min.Elongation at Break(%) | Max.Abrasion Loss(mm3) |

| DIN-Z | Germany | DIN22102 | 15 | 350 | 250 |

| DIN-Y | Germany | DIN22102 | 20 | 400 | 150 |

| DIN-X | Germany | DIN22102 | 25 | 450 | 120 |

| DIN-W | Germany | DIN22102 | 18 | 400 | 90 |

| RMA-I | U.S.A | RMA | 17 | 400 | 150 |

| RMA-II | U.S.A | RMA | 14 | 400 | 200 |

| ARPM RMA-I | U.S.A | ARPM | 17 | 400 | 125 |

| ARPM RMA-II | U.S.A | ARPM | 14 | 400 | 175 |

| ISO-L | International | ISO -10247 | 15 | 350 | 200 |

| ISO-H | International | ISO -10247 | 24 | 450 | 120 |

| ISO-D | International | ISO -10247 | 18 | 400 | 100 |

| AS-N | Australian | AS -1332 | 17 | 400 | 200 |

| AS-M | Australian | AS -1332 | 24 | 450 | 125 |

| AS-A | Australian | AS -1332 | 17 | 400 | 70 |

| SANS-N | South Africa | SANS-1173 | 17 | 400 | 150 |

| SANS-M | South Africa | SANS-1173 | 25 | 450 | 120 |

| SANS-A | South Africa | SANS-1173 | 18 | 400 | 70 |

| BS-M | UK | BS-490 | 24 | 450 | 120 |

| BS-N | UK | BS-490 | 17 | 400 | 200 |

| IS-N-17 | India | IS 1891 | 17 | 400 | 200 |

| IS-M-24 | India | IS 1891 | 24 | 450 | 150 |

| JIS-G | Japan | JIS-K 6332 | 14 | 400 | 250 |

| JIS-L | Japan | JIS-K 6332 | 15 | 350 | 200 |

| JIS-D | Japan | JIS-K 6332 | 18 | 400 | 100 |

| JIS-H | Japan | JIS-K 6332 | 24 | 450 | 120 |

| GB-H | China | GB/T 7984 | 24 | 450 | 120 |

| GB-D | China | GB/T 7984 | 18 | 400 | 100 |

| GB-L | China | GB/T 7984 | 15 | 350 | 200 |

We also supply conveyor idler, pulley and conveyor bracket, please log on our brach company www.conveyoroller.com for more information!

Tags: Abrasion resistance of EP conveyor belts,Advantages and features of EP conveyor belts,aggregate ep conveyor belt,anti-static properties of ep conveyor belt,Applications and industries of EP conveyor belts,Bulk material ep conveyor belt,Buying guide for EP conveyor belts,Cement ep conveyor belt,Chemical resistance of ep conveyor belt,Chemical resistance of EP conveyor belts,coal ep conveyor belt,Comparison of EP conveyor belts with other types,crushing plant ep conveyor belt,Ep conveyor belt specification,Ep fabric conveyor belt,EP rubber conveyor belt,ep1000/3 conveyor belt,ep1000/5 conveyor belt,ep1250 conveyor belt,ep1250/4 conveyor belt,ep1250/5 conveyor belt,ep160 conveyor belt,ep250 conveyor belt,ep315/2 conveyor belt,ep315/3 conveyor belt,ep400 conveyor belt,ep400/3 conveyor belt,ep630 conveyor belt,EP630/4 conveyor belt,ep800/3 conveyor belt,ep800/4 conveyor belt,ep800/5 conveyor belt,Installation and commissioning tips for ep conveyor belt,internation standards for ep conveyor belt,International standards and certifications for EP conveyor belts,Maintenance and care for EP conveyor belts,Manufacturers of EP conveyor belts,mining EP conveyor belt,polyester conveyor belt,Pricing and cost of EP conveyor belts,quarry ep conveyor belt,Reliability and durability of EP conveyor belts,Rubber conveyor belt,steel plant ep conveyor belt,Temperature range for EP conveyor belts,tensile strength of ep conveyor belt,Tensile strength of EP conveyor belts,Waterproof properties of EP conveyor belts