How does the bending of EP fabric affect the working life of the conveyor belt?

When we talk about the impact-resistant capability, elongation, wrinkle in the bottom cover of rubber conveyor belt, we have to mention the bending of EP fabric, this index is more important than strengthen of conveyor belt, that is an index that always ignored by some of conveyor belt manufacturer.

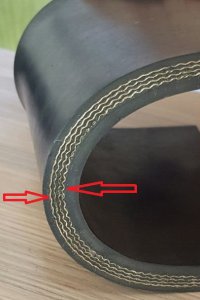

As we see on the picture of bend situation of EP conveyor belt on the conveyor pulley surface, we can find the top EP layer must elongate so that will make the bottom EP layer keep original length, if the top EP layer could not elongate enough, that will make the bottom EP layer wrinkle, that will lead to the same wrinkle on the surface of bottom cover.

For NN(Nylon) layer, because of low polyamide modulus, it will easy elongate even in small external force, so for NN layer rubber conveyor belt, the top fabric will be easy elongation, that makes bottom layer in an original length, so the wrinkle situation will be not always happened in NN layer conveyor belt, also the NN conveyor belt is relatively soft than EP conveyor belt.

But for EP layer conveyor belt, because of EP character, the original polyester tensile resistance and bend resistance modulus is 5 times than NN fabric, it is not easy to elongation and bending if there was no special dispose during EP producing process, the wrinkle situation will be serious in conveyor belt, that lead to huge cut stress between bottom cover and fabric because of rubber and fabric serious distortion, after long time conveyor belt running, the bottom cover rubber will peel off to fabric, and the working area between conveyor belt and conveyor pulley will be linear contact but facial contact because of wrinkle situation, that will affect the drive power in very lower level and easy to slip, and the bottom cover will be damaged soon.

Normally, the rubber conveyor belt manufactory use adding thickness of skim rubber to solve this situation, but that will lead to higher cost, the right method to solve this problem is that increase shrinkage of fabric, increase bending rate in EP fabric longitude direction, that means to decrease the original modulus of longitude direction, that will make the longitude fabric like a rubber band as bending force, another way is that use EP fabric layer as less as possible, extra layer will make the over thickness of layer area, that will lead to bottom layer in huge cut stress as touching conveyor pulley, last but not least, make reasonable conveyor pulley diameter, small diameter conveyor pulley will damage the conveyor belt more than big diameter conveyor pulley.

Tags: EP conveyor belt