EP Conveyor Belt EP400/3,EP500/4,EP630/4,EP800/4-SUNGDA GROUP

General Introduction:

In the specification description of conveyor belts, we often see specifications such as EP315/3, EP400/3, EP500/4, EP630/4, EP800/4, EP1000/4, etc. What grades of conveyor belts do they represent?

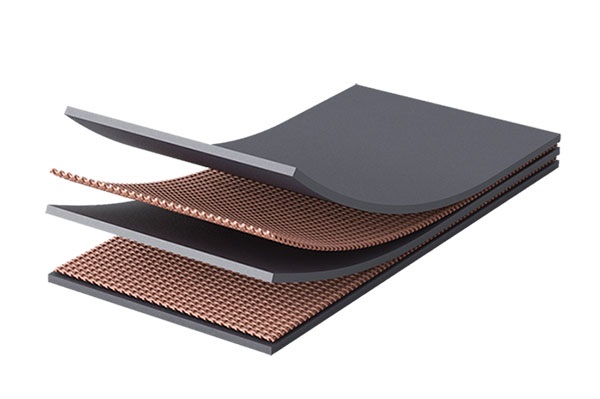

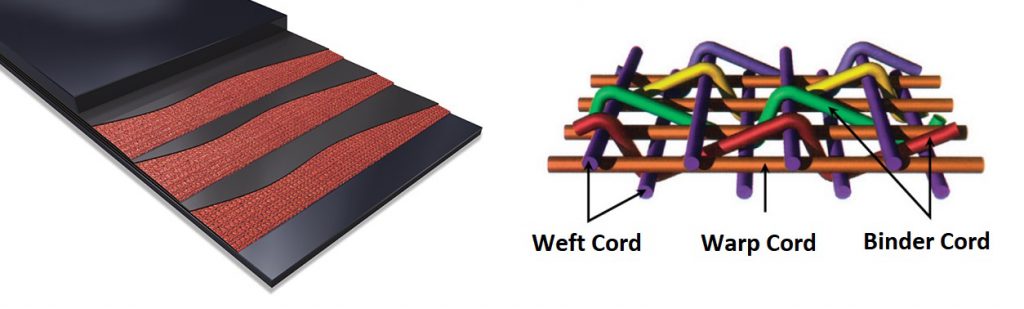

EP conveyor belt is also called polyester conveyor belt (NP conveyor belt in the U.S), the “EP” is short for Polyester fabric, which includes polyester toward longitudinal(warp) and polyamide for latitude(weft), EP fabric plies are sandwiched between rubber skim coats for adhesion and load support, bottom and top cover compounds are added for maximum protection of the belt carcass.

The EP conveyor belt consisting of 2 to 6 EP fabric plies, EP rubber conveyor belt has the same merit as Nylon(NN) conveyor belt, its tensile carcass is made of warp polyester and weft nylon knitted fabric, its performance is characterized by low elongation in the warp direction and excellent troughing formation in the longitudinal direction. The strength of the EP conveyor belt will not decrease in a humid environment, no mildew occurs also, the initial modulus of the polyester is high, and a lower safety factor can be taken, it is suitable for conveying materials under medium, long-distance, and high load and high-speed conditions.

EP rubber conveyor belt is widely used in the mining and processing industries for transporting bulk or lumpy materials such as quarrying, ore, coke, aggregates, crops, sand, clinker, chemicals, construction materials, etc. EP fabric has the advantages of:

1.Lower longitudinal elongation.

2.Full resistance to mildew, moisture and rotting.

3.Good flexibility and trough ability.

4.Short take-up lengths.

5.Suitable for middle and long-distance transportation of higher load and speed.

EP fabric also has excellent compatibility with other rubbers, so it can be combined with any type of cover grade to make it a perfect match for almost any application, this allows EP conveyor belt to convey basically any type of product in any environment, from fine powders to large lumps, from dry to greasy materials, from extremely cold to very hot conditions.

Due to the above excellent performance of EP conveyor belt and its very economical price, it has become the most widely used type of conveyor belt in the world, taking light and heavy duty carrying work in the fields of seaport, steel mill, mining, cement plant, metallurgy, agriculture, electric power, chemical industry etc.

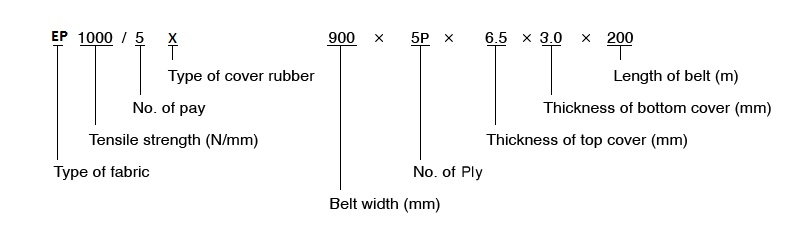

Key Symbols of EP Conveyor Belt:

Representation method of EP conveyor belt: EP1000/5 900*5 (6.5+3.0)=200m

The polyester layer represented by EP, EP1000 means the total tensile strength of belt is 1000N/mm, 5 represents the number of EP layers, so each EP layer will be 200N/mm(each EP layer type is EP200 correspondingly), 900 represents the width of the conveyor belt, , 6.5 represents the thickness of the upper cover rubber, and 3.0 represents the bottom cover rubber. the 200 represents the length of the conveyor belt.

Other Specification:

Tensile strength and width produced by SUNGDA: Tensile strength: 300~3200N/mm Width: 500~5200mm.

As for single EP layer type, the existing types are: EP100, EP150, EP200, EP250, EP300, EP350, EP400. The EP200 is used more and meets the basic required pulling force, the EP150 is second, and the EP400 is basically not used except super heavy duty field or long distance above 350 meters. The common ep conveyor belt type could be:

2-ply belts: EP315/2 EP400/2 EP500/2 EP630/2 EP800/2

3-ply belts: EP315/3 EP500/3 EP630/3 EP800/3 EP1000/3 EP1250/3

4-ply belts: EP630/4 EP800/4 EP1000/4 EP1250/4 EP1600/4

5-ply belts: EP800/5 EP1000/5 EP1250/5 EP1600/5 EP2000/5

In addition, EP has different characteristics such as heat resistance, cold resistance, oil resistance, acid and alkali resistance, flame retardancy and anti-static, The above characteristics allow EP conveyor belts to have different application variants, such as EP heat-resistant conveyor belts, EP fire resistant conveyor belts, EP oil-resistant conveyor belts, EP Chevron conveyor belts, and EP pipe conveyor belts etc.

What is the Safety Factor of Conveyor Belt?

Comparison of RMA and DIN Standard for Conveyor Belts

EP Conveyor Belt Layer is the More the Better?

Max.5000 mm Width Belt for Horizontal Vacuum Belt Filter

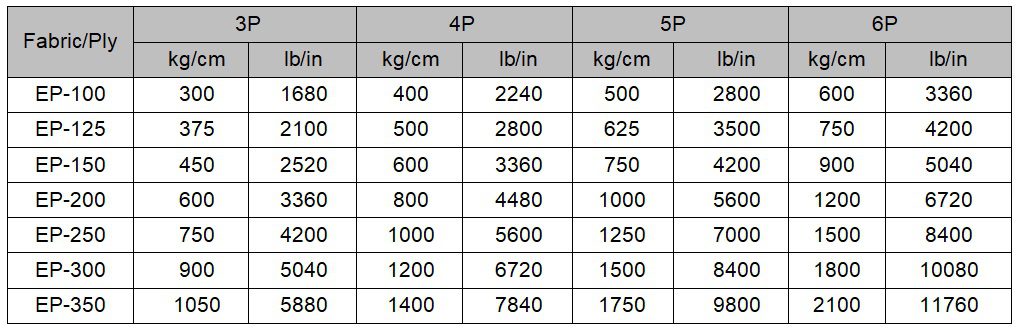

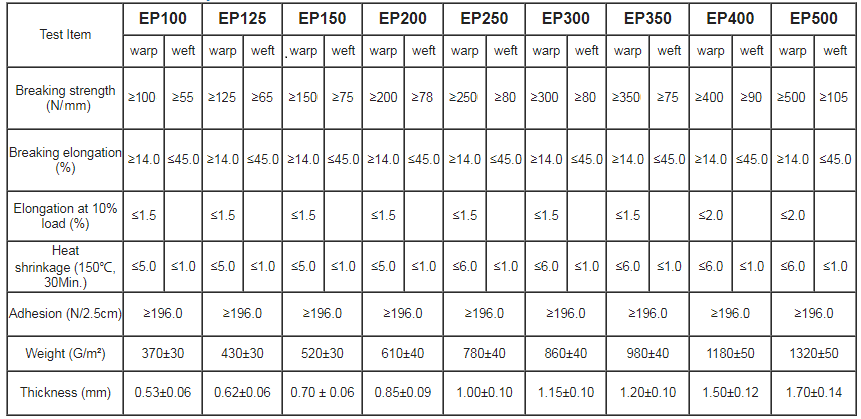

EP Fabric Technical Specification(per ply):

Muti-ply EP Fabric Grade (Tensile Strength kg/cm, PIW):

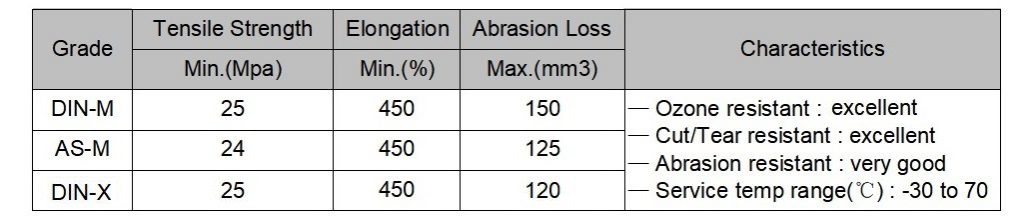

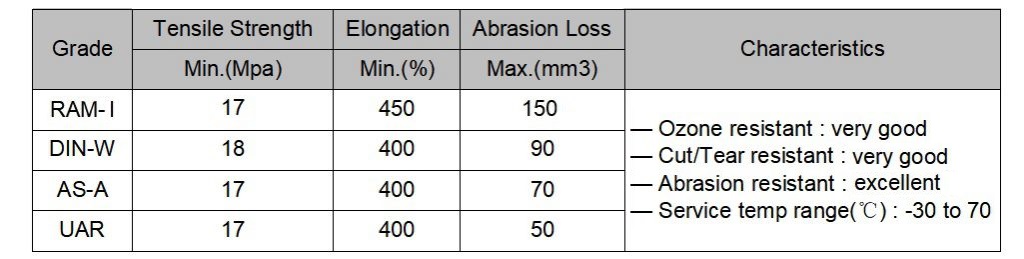

The Most Popular Rubber Cover Standard of EP Conveyor Belt and Applications:

These cover rubbers are used for heavy impact, large sized lumps, and sharp material.

and suitable for handling crushed rock, limestone,coal, slag, etc.

The following sheet is currently the main internationally popular EP conveyor belt implementation standard:

| Cover Grade | Country | Applicable Standards | Min.Tensile Strength(Mpa) | Min.Elongation at Break(%) | Max.Abrasion Loss(mm3) |

| DIN-Z | Germany | DIN22102 | 15 | 350 | 250 |

| DIN-Y | Germany | DIN22102 | 20 | 400 | 150 |

| DIN-X | Germany | DIN22102 | 25 | 450 | 120 |

| DIN-W | Germany | DIN22102 | 18 | 400 | 90 |

| RMA-I | U.S.A | RMA | 17 | 400 | 150 |

| RMA-II | U.S.A | RMA | 14 | 400 | 200 |

| ARPM RMA-I | U.S.A | ARPM | 17 | 400 | 125 |

| ARPM RMA-II | U.S.A | ARPM | 14 | 400 | 175 |

| ISO-L | International | ISO -10247 | 15 | 350 | 200 |

| ISO-H | International | ISO -10247 | 24 | 450 | 120 |

| ISO-D | International | ISO -10247 | 18 | 400 | 100 |

| AS-N | Australian | AS -1332 | 17 | 400 | 200 |

| AS-M | Australian | AS -1332 | 24 | 450 | 125 |

| AS-A | Australian | AS -1332 | 17 | 400 | 70 |

| SANS-N | South Africa | SANS-1173 | 17 | 400 | 150 |

| SANS-M | South Africa | SANS-1173 | 25 | 450 | 120 |

| SANS-A | South Africa | SANS-1173 | 18 | 400 | 70 |

| BS-M | UK | BS-490 | 24 | 450 | 120 |

| BS-N | UK | BS-490 | 17 | 400 | 200 |

| IS-N-17 | India | IS 1891 | 17 | 400 | 200 |

| IS-M-24 | India | IS 1891 | 24 | 450 | 150 |

| JIS-G | Japan | JIS-K 6332 | 14 | 400 | 250 |

| JIS-L | Japan | JIS-K 6332 | 15 | 350 | 200 |

| JIS-D | Japan | JIS-K 6332 | 18 | 400 | 100 |

| JIS-H | Japan | JIS-K 6332 | 24 | 450 | 120 |

| GB-H | China | GB/T 7984 | 24 | 450 | 120 |

| GB-D | China | GB/T 7984 | 18 | 400 | 100 |

| GB-L | China | GB/T 7984 | 15 | 350 | 200 |

Related Literatures:

Top 5 China Rubber Conveyor Belt Manufactures In 2022

Why 87.6% of companies choose Chinese conveyor belt manufactures?

How to choose right EP conveyor belt?

6 Steps to help you judge the quality of the EP conveyor belt in 1 minute.

SUNGDA Conveyor Belt Co.,Ltd

SUNGDA Conveyor Belt Testing Lab:

We also supply conveyor idler roller, pulley and conveyor bracket, please log to our branch company official website www.conveyoroller.com or click below picture for idler roller producing video.

SUNGDA Regular Customers:

How to identify the quality of the EP conveyor belt in 1 minute?

These adjustment methods can make the conveyor belt transport 50 tons more per hour!

What are the advantages of EP conveyor belts compared to other fabric carcass conveyor belt?

How does the bending of EP fabric affect the working life of the conveyor belt?

Tags: Ep conveyor belt specification,EP rubber conveyor belt,ep315/3 conveyor belt,ep400/3 conveyor belt,EP500/4 conveyor belt,EP630/4 conveyor belt,ep800/3 conveyor belt,steel mill