How to choose a cost-effective mining conveyor belt?

Carcass selection of the mining conveyor belt:

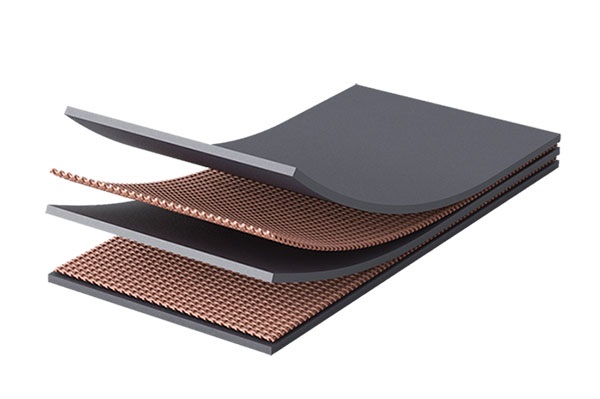

The performance of the mining conveyor belt is bound with the core material, carcass and number of layers. The cotton canvas multi-layer conveyor belt is heavyweight, high energy consumption, and has low strength, overmuch layers are not resistant to fatigue, and is prone to mold and corrosion.

A nylon conveyor belt (NN)with high strength, large elasticity, lightweight, good impact resistance, and bending resistance, good troughing formation performance, mildew resistance, water-resistance, and other properties are better than ordinary cotton layer conveyor belt, but NN layer conveyor belt has the disadvantage of large elongation. When the tension stroke of the conveyor line can be set longer, nylon rubber belts are preferred. The strength of polyester belt cores(EP layer conveyor belt) is similar to polyamide and has all the advantages of nylon conveyor belts. Its elastic modulus is higher than nylon, low elongation, good dimensional stability, it is an ideal mining industrial commonly used conveyor belt, while the steel cord conveyor belt has high strength, good troughing formation, small elongation, and short tension stroke, especially suitable for large capacity, high belt speed, long-distance mining transportation requirements.

Selection of rubber cover:

The rubber cover includes cover rubber material, surface morphology, and thickness. The main components of the cover are various rubbers and plastics (structure: synthetic resin, plasticizer, stabilizer, colorant). There will be great differences in the properties of various rubbers, such as natural rubber and styrene-butadiene rubber, they have good shock absorption and abrasion resistance, the Max. abrasion resistant of rubber cover can be up to 50mm3, the Max.tensil strength of rubber cover can reach to 24Mpa, which can be used for hard or sharp ming such as iron, copper, molybdenum, etc., EPDM rubber is particularly heat-resistant, and cyanide rubber is oil-resistant good performance can be used on mining post-processing, butyl rubber is both heat-resistant and oxidation-resistant, can be used on corrosive mining such as phosphorite mining, salt, gypsum mining, etc, so the choice of which type of covering material must be based on the type of commonly used conveying mining materials, operating conditions, and working environment.

In addition, the increase in the thickness of the cover layer is also conducive to improving the impact resistance and abrasion resistance of the rubber conveyor belt. Especially today, the cotton canvas belt layer has been replaced by a synthetic fiber fabric layer such as NN and EP layer which is thinner and stronger, in order to improve the overall performance of the belt, it is necessary to correspondingly increase the thickness of the rubber cover, in order to give full play to its advantages and improve the service life of the mining conveyor belt.