Why the EP630/4 is the most porpular EP conveyor belt type ?

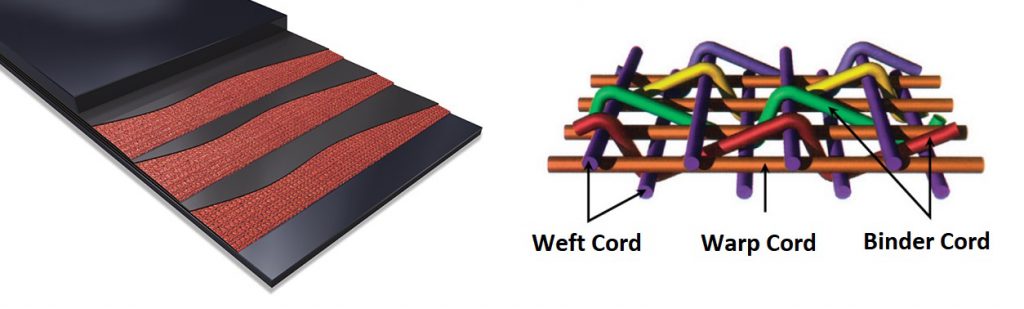

When choosing a conveyor belt model, we often see descriptions of EP315/3, EP630/4, EP400/3, EP800/4, EP1000/4, etc. What does this mean? We use EP630/4 as an example:

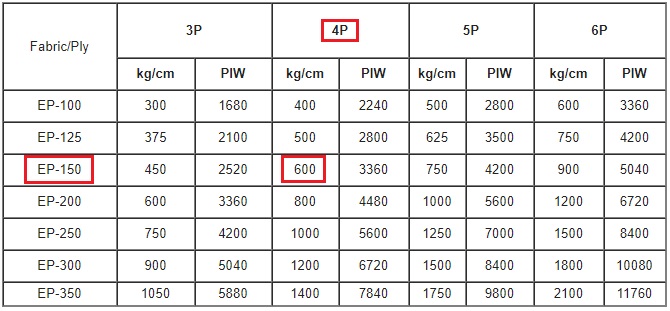

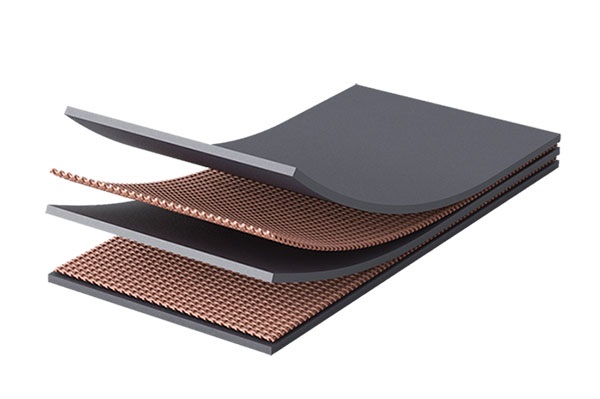

EP630/4 conveyor belt is a strong layer often used in ep conveyor belts. EP630 represents the total tensile strength of the strong layer is 630kN/mm, 4 represents the fabric layer is 4 layers, then EP630/4 conveyor belt represents the total tension of the polyester fiber conveyor belt is 630kN/mm(the type of each layer will be 630/4=EP150 or EP160).

The reason why EP630/4 EP conveyor belt models are the most porpular is because the most of the conveyor lines in the world are short distances under 200 meters and low conveyance. Such conveying distances will longitudinally pull the conveyor belt. The tensile strength is not very high. EP630/4 conveyor belt can fully meet the transportation requirements. On the other hand, the 4-layer strong layer requires a 500-600mm conveyor pulley diameter, and such a conveyor pulley diameter is currently the most common on the transportation site. Finally, because the EP630/4 type conveyor has a strong versatility and can be applied to most conveyor sites, it is also very popular in the used conveyor belt market, and the economic benefits will be maximized.

In addition, EP630/2, EP300/3, EP400/3, EP400/4, EP500/3, EP500/4 can be expressed in this way, they correspond to different conveyor belt tension, but no matter which The models are different from the type of ester (EP) conveyor belt, which tensile strength must be selected from the following points:

1 The transportation distance is usually longer and the required pulling force is larger. Because long-distance transportation needs to achieve strong tear resistance.

2 The amount of material transported per hour, under other conditions being the same, the greater the amount of work to be transported per hour, the greater the pulling force to be achieved, because the faster the speed per hour, the basic conveyor is in operation Under high speed.

3 The fineness, size and strength of the transported materials are also the size and weight of the materials. For example, under the same circumstances, the transportation of large ores is much larger than the transportation of powdered materials.

4 conveying angles. Generally, the greater the conveying angle, the greater the lifting force and the greater the pulling force of the conveyor belt.

EP conveyors have many different properties, such as heat resistance, cold resistance, oil resistance, acid and alkali resistance, flame resistance, antistatic properties, etc., and can be used in complex transportation environments according to different transportation environments. For example, heat resistance, oil resistance, cold resistance, acid and alkali resistance, flame retardant, antistatic agent, etc., depending on the condition of the material and the temperature of the transportation environment. In each area, the choice of this attribute is different.

EP conveyor belt maintenance:

1 Must be installed correctly during the installation process. After installation, a trial run must be conducted to see if the EP conveyor belt has not been installed or deviated.

2 EP conveyor belts (if not used) must be ventilated and dry, and must be turned frequently.

3 During use, the EP conveyor belt should be checked, and the worn area should be repaired in time. If the damage exceeds 70%, the conveyor belt should be replaced in time.

SUNGDA CONVEYOR BELT CO.,LTD

Tags: EP conveyor belt,ep315/3 conveyor belt,ep400 conveyor belt,ep400/3 conveyor belt,ep630 conveyor belt,EP630/4 conveyor belt,ep800/3 conveyor belt,ep800/4 conveyor belt