7 main reasons for “tearing” of EP conveyor belts and preventive storage measures

There are two types of tearing in EP conveyor belts: transverse tearing and longitudinal tearing. The transverse tearing is mostly caused by the cloth layer or wire rope break in the EP EP conveyor belt, which generally belongs to the quality of the ...

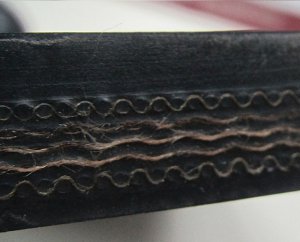

The core of the conveyor belt-carcass structure and formula

Common carcass materials for heat-resistant conveyor belts: polyester fabric(EP), nylon(NN), aramid fabric, cotton fabric(CC), etc. (1)In addition to the above-mentioned commonly used carcass materials, heat-resistant belts, steel cord(ST), new hollo...

Why is the EP conveyor belt splicing section easy to crack and disconnect?

The strength at the splicing section of the EP conveyor belt is lower than that of the normal belt body. When mechanically connected, the strength of the splicing section can only reach 40-50% of the strength of the belt. When the quality of the cold...

What should be paid attention to when transporting and storing the conveyor belt

What should be paid attention to when transporting and storing the conveyor belt (1) Transportation of conveyor belt 1. The outer packaging of the conveyor belt protects the conveyor belt during handling and storage, so care must be taken not to da...

How to solve the abrasion problem of EP conveyor belts for mining

Mining EP conveyor belt wear will bring large economic losses to manufacturers. How to avoid conveyor belt wear is a topic that all manufacturers are concerned about. SUNGDA Conveyor Belt Co., Ltd. puts forward some suggestions to avoid conveyor belt...

How to improve the performance of fire resistant conveyor belts

The fire-resistant conveyor belt usually consists of working surface covering rubber, non-working surface covering rubber and belt fabric ply. The working surface covering rubber is made of halogenated butyl rubber, ethylene-propylene rubber, styrene...

What standards does the EP conveyor belt abrasion rate follow?

For EP rubber conveyor belts, generally comply with DIN53516 standard. DIN 53516 for wear abrasion is to test sample mass loss by rubbing on abrasive paper under certain pressure. Calculate the volume loss(mm3) by sample density and the loss of stand...

How to avoid “side-travel” problem of EP conveyor belt?

The conveyor structure must be “True” (relative to the center-line) and “Level” (side-to-side). All pulleys, snub rollers, carrying and return idlers must be “Square” with the frame (perpendicular to the belt center-line) and parallel to each other....

What affects the service life of EP conveyor belts?

The EP conveyor belt is one of the most important transportation equipment in the mining industry. Large mining companies have large transportation systems, long transportation distances, and long operating hours. Reasonably determining and trying to...

How to Choose the Cover Thickness of Conveyor Belt?–SUNGDA Conveyor Belt

There are many factors that influence top and bottom belt cover thickness: 1. Top cover selected for wear life (abrasion, gouging; temperature environment) based on rock properties, chute design that defines impact and shear, and product temp...