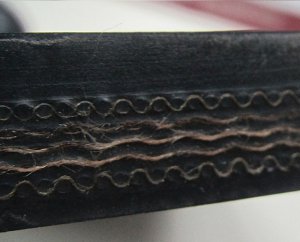

The core of the conveyor belt-carcass structure and formula

Common carcass materials for heat-resistant conveyor belts: polyester fabric(EP), nylon(NN), aramid fabric, cotton fabric(CC), etc.

(1)In addition to the above-mentioned commonly used carcass materials, heat-resistant belts, steel cord(ST), new hollow fibers or cloth cores impregnated with fluoroplastic heat-resistant fibers can also be used as carcass materials to improve the service temperature, strength and service life of conveyor belts. In order to improve the adhesion between the carcass material and the rubber, the surface of the carcass material should be treated. The chemical fiber fabric is impregnated to bond the adhesive resin to the surface of the fabric. RFL, resorcinol, formaldehyde, and latex are the main binders, and isocyanate can be incorporated into polyesters with poor affinity. For aramid, the two-step impregnation of isocyanate, epoxy resin and RFL resin gradually transforms into one-step impregnation.

(2) The adhesion between the steel cord and the rubber is not only the steel cord, the copper or zinc plating on the surface, but also exerts a special coordination effect on the rubber compound. Mainly add organic cobalt salt, and use high sulfur formula to form an adhesive layer to promote the strong adhesion of rubber and steel cord rubber. Organic cobalt salts have now evolved from cobalt naphthenate and cobalt stearate to cobalt decanoate and cobalt borate, which have a high cobalt content and can quickly release cobalt salts at the vulcanization temperature, and use vulcanization accelerators containing cobalt salts .

Cover rubber for heat-resistant conveyor belt: The heat resistance of the conveyor belt depends on the heat resistance of the cover rubber. In addition, there are many new types of covering rubber, such as bromobutyl rubber compound and EPDM rubber, neoprene neoprene rubber, ethylene propylene rubber and polyalkylene siloxane compound to improve the coverage of rubber Heat resistance.

Tags: EP conveyor belt,Steel cord conveyor belt