You should know these details before selecting EP conveyor belt type

1. When the twist coefficient of the material is increased, that is, the twist is increased. Like a steel wire wound into a spiral spring, the more turns, the lower the modulus, and the better the fatigue resistance. For EP fabric(EP ), increasing th...

How to extend the life of the EP conveyor to 3 years

Conveyors are used in all walks of life due to their advantages of smooth operation and continuous transportation capacity. In recent years, due to the gradual increase in the production capacity of major mines, the transportation capacity of conveyo...

7 reasons and solutions for EP conveyor belt slipping

Slipping is one of the common failures of belt conveyors. Once a slipping failure occurs, it is easy to cause the material to fall, block the feeding tube, wear the belt, and break the belt, which will cause the belt conveyor to fail to operate norm...

How to select the edge type of ep conveyor belt, cut edge or mould edge?

There are two edge types of ep conveyor belt: “molded edge” and “cut edge”, in general, most customers are more inclined to choose the molded edge conveyor, because the molded edge conveyor belt can protect the carcass of a fabric belt ...

These adjustment methods can make the EP conveyor belt transport 50 tons more per hour!

With the increasing demand and efficiency of modern transportation, long-distance, large capacity, high belt speed and other types of transportation systems have become a trend and gradually become popular, but with it, the resistance when conveying ...

Pay attention to these details, the working life of the EP conveyor belt can reach at least 5 years

1. The relationship between the diameter of conveyor pulley and the layer of the EP conveyor belt, the matching of the drive pulley, the tail pulley, and the requirements for the trough angle of the conveyor bracket should be selected reasonably acco...

What are the factors that affect the appearance of the EP conveyor belt?

In the production, there will be “water wave” and “longitudinal wave” in the EP conveyor belt. This phenomenon is mainly caused by the uneven vulcanization of the EP conveyor belt. The thermal dimensional stability of the EP fabrics at high temperat...

EP conveyor belt longitudinal wave phenomenon and solution

EP conveyor belts always produce longitudinal waves during the production of vulcanization, which will affect their normal use and work efficiency. If it is serious, it will lead to a decrease in the service life of EP conveyor belts. So how to avoid...

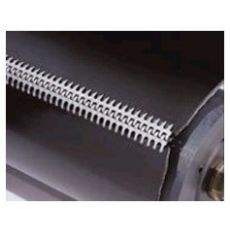

How many methods of make EP conveyor belt joint?

All EP conveyor belts must be connected in a endless shape to be used, so the quality of the EP conveyor belt joints directly affects the service life of the conveyor belt and whether the conveyor line can run smoothly and smoothly. Common methods fo...

What is the quality standard of ordinary EP conveyor belt?

(Including high-strength nylon conveyor belt) products implement the DIN22102 standard. Cover layer: Tensile strength is not less than 15Mpa, elongation at break is not less than 350%, wear loss is ≤200mm3, interlayer adhesion strength is between no...