7 reasons and solutions for EP conveyor belt slipping

Slipping is one of the common failures of belt conveyors. Once a slipping failure occurs, it is easy to cause the material to fall, block the feeding tube, wear the belt, and break the belt, which will cause the belt conveyor to fail to operate normally. This article analyzes the 7 major causes of slippage and solutions for everyone.

1.Insufficient tension of the EP conveyor belt

When the EP conveyor belt does not have sufficient tension, sufficient frictional driving force will not be generated between the driving wheel and the conveyor belt, and the conveyor belt and load movement cannot be pulled. The stroke of the screw or hydraulic tensioning device is not enough or adjusted incorrectly, the weight of the hammer and the weight of the car-type tensioning device is not enough, and the jamming of the mechanism will cause insufficient tension of the belt conveyor, causing slippage.

Solution:

(1) The belt conveyor with a screw or hydraulic tensioning structure can increase the tension by adjusting the tensioning stroke.

(2) Belt conveyors with a hammer-tightening and car-type tightening structure can be handled by increasing the weight of the counterweight or eliminating the mechanism jam. When increasing the configuration of the tensioning device, it can be added to the conveyor belt without slipping, and it should not be added too much, so as not to cause the conveyor belt to bear unnecessary excessive tension and reduce the service life.

2. The rubber lagging of driving pulley is severely worn.

After the belt conveyor runs for a long time, the rubber surface of the driving pulley and its grooves will be severely worn, which will cause the friction coefficient of the surface of the driving pulley to decrease and the friction force to decrease, which will cause the belt to slip.

Solution:

It should be repackaged or replaced with a new conveyor drive pulley. Daily inspection of the driving conveyor pulley should be checked.

3.Attachment on the non-working surface of the conveyor belt

Due to changes in the natural environment, on-site under frame washing, equipment maintenance, etc., attachments that have a certain lubricating effect on the non-working surface of the conveyor belt will gather on the surface area of the driving pulley during operation, causing the friction between the conveyor pulley and the conveyor belt to be significantly reduced. , Causing slipping.

Solution:

The source of the attachment should be identified and cut off. If the source cannot be cut off, sprinkle some rosin powder on the drum (blown in with a blower).

4.Overload of belt conveyor

Due to improper operation or heavy load shutdown, the belt conveyor is carrying excessive loads during operation, causing the belt to slip.

solution:

(1) Observe the current of the belt conveyor and the scale of the electronic conveyor belt to control the amount of material and avoid overload operation.

(2) Try to avoid heavy load shutdown and overload.

5. The head tribe material tube is blocked

When the blanking pipe is blocked, a large amount of material will accumulate on the head and the non-working surface, crushing the conveyor belt and causing slippage.

Solution:

Care should be taken to observe the changes in the material on the conveyor belt. When stickiness occurs, the inspection frequency of the head tube should be increased, and the sticky material in the drop tube should be cleaned in time to avoid blockage.

6. The EP conveyor belt is partially scratched

When the EP conveyor belt is locally hindered by a strong force, it will cause the belt conveyor to slip. For example, the head of the belt conveyor, the foreign material stuck in the tail tube, the tail does not turn to the drum, etc.

Solution:

The observation of the belt conveyor current should be strengthened, and the machine should be stopped immediately for inspection when abnormal current changes occur.

7. The wrap angle or friction coefficient between the driving wheel and the EP conveyor belt is too small

Generally, the wrapping angle between the driving wheel and the conveyor belt should not be less than 120 °, which is too easy to cause slippage. The too small friction coefficient between the driving wheel and the conveyor belt will also cause the conveyor belt to slip.

Solution:

When the wrap angle between the driving wheel and the EP conveyor belt is low and the position of the adjusting tensioner is still effectively increased, the design needs to be modified. If the friction coefficient is too small, carefully observe whether the surface of the driving wheel of the conveyor is too smooth, otherwise use a knurled structure or inlay a layer of rubber before testing.

Summary

Skid is one of the common failures of belt conveyors. We need to standardize operation, carefully check and maintain to avoid the occurrence of slippage, and ensure the safe and stable operation of the belt conveyor system.

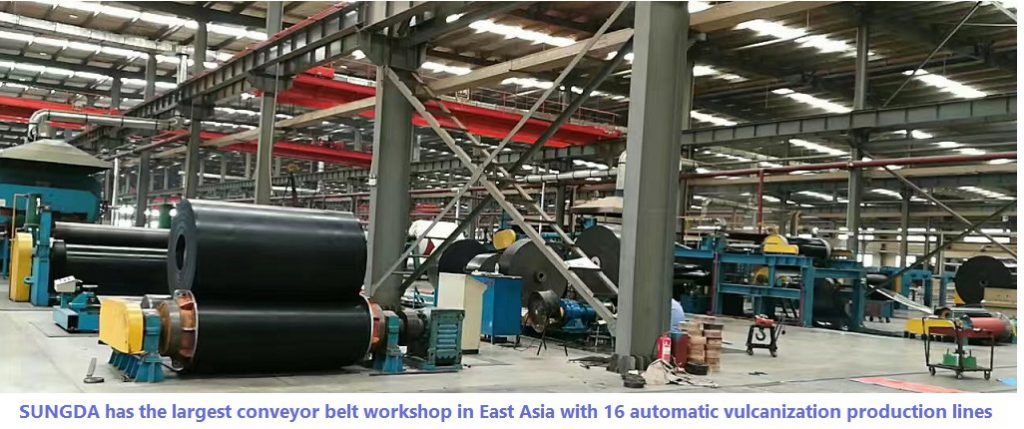

SUNGDA EP rubber conveyor belt series such as mining conveyor belt, heat resistant conveyor belt, and flame resistant conveyor belt adopt Continental conveyor belt technology, are developed to assure you of the high-quality rubber conveyor belt.

The combination of polyester in warp and nylon infilling provides technical low-stretch, high impact abuse resistance. Recommended for transporting abrasive materials, such as mining, rock, stone, ore, glass, granite, etc, for more information, please log on our website: https://www.sungda.com or email us by overseas.sungda@gmail.com

Tags: CONVEYOR BELT SLIPPING,EP conveyor belt