6 Steps to Help You Judge The Quality of The EP Conveyor Belt in 1 Minute.

1.Checking the thickness of the top rubber of the EP conveyor belt: The thickness of the top rubber directly affects the life of the EP conveyor belt. Some EP conveyor belts are thick as a whole, but the top rubber is very thin, only one or two millimeters thick. This conveyor belt has a very short working life, once the top rubber is worn and leaked out of the EP fabric layer, the entire conveyor belt will basically be scrapped. (Pictured)

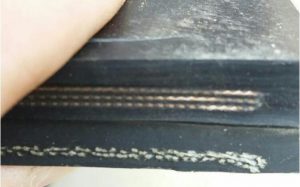

2.Checking the EP layer: Conveyor belts with more EP layers have great longitudinal tensile strength, which is suitable for long-distance and large-volume transportation, but the number of layers does not mean durability. Its life depends on the thickness of the top and bottom rubber and the rubber Quality (pictured) inferior conveyor belts and conveyor belts imported from Germany.

3.Smell: EP conveyor belts with high specific gravity of natural rubber have a light odor and no nose choking, and conveyors with high specific gravity of reclaimed rubber have a very pungent odor.

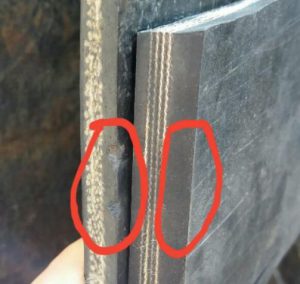

4.Checking the edge of the EP fabric belt: the high-quality EP fabric on the edge of the conveyor belt is neat and tidy, and the EP fabric on the edge of the inferior EP conveyor belt is uneven in length. It is easy to separate the glue during use, which greatly reduces the service life.

5.There is another way to test the content of natural rubber in EP conveyor belts. Use your nails to pinch the rubber surface for 3-5 seconds. The conveyor belt that recovers quickly and is not pinched off contains high natural rubber content. On the contrary, the belt contains natural rubber. Less rubber is mostly reclaimed rubber.

6.Checking the tensile strength of rubber: EP conveyor belt rubber with high natural rubber is stretched and long, like rubber bands, with high elongation. Conveyor belts with high reclaimed rubber have a short rubber stretch rate and break when pulled.

Tags: EP conveyor belt,QUALITY