How many methods of make EP conveyor belt joint?

All EP conveyor belts must be connected in a endless shape to be used, so the quality of the EP conveyor belt joints directly affects the service life of the conveyor belt and whether the conveyor line can run smoothly and smoothly. Common methods for EP conveyor belt joints include mechanical joints, cold bonded joints, and hot vulcanized joints.

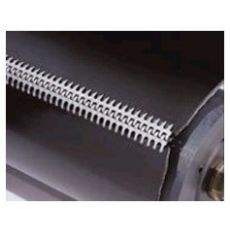

1. Mechanical joint method

Generally speaking, the belt buckle joint is used. This joint method is convenient and convenient, and economical, but the joint has low efficiency and is easy to be damaged, which has a certain influence on the service life of the EP conveyor belt product. The snap connection is equivalent to 28%-45% of the strength of the conveyor belt itself.

2. Cold bonding head method

That is, a cold-adhesive adhesive is used to make the EP conveyor belt joint. This joint method is more efficient and mechanical than the mechanical joint and should have a better joint effect, but from the practical point of view, because the process conditions are difficult to master, the quality of the adhesive has a great influence on the joint. So it is not very stable. Bonding with cold glue is equivalent to 40%-55% of the strength of the conveyor belt itself.

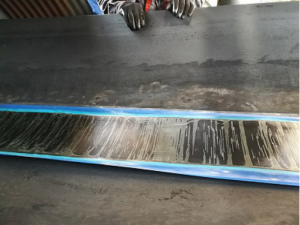

3. Hot vulcanization joint method

The practice has proved to be the most ideal joint method, which can ensure high joint efficiency, is also very stable, and has a long joint life and is easy to grasp. However, there are disadvantages such as troublesome process, high cost, and long joint time. Bonding with mechanical heat vulcanization is equivalent to 60%-80% of the strength of the EP conveyor belt itself.

Tags: EP conveyor belt