What is the Steel Cord Conveyor Belt?

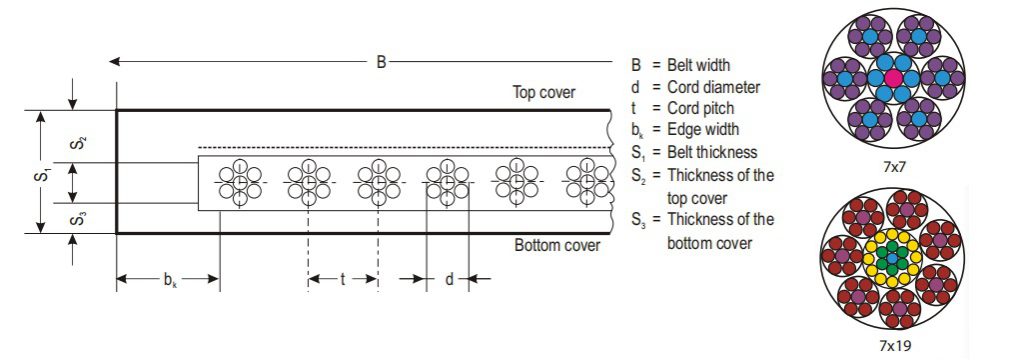

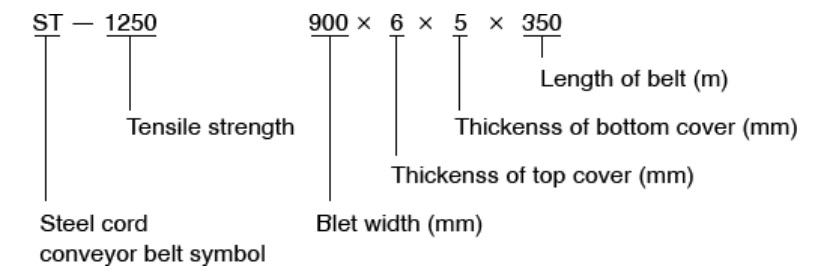

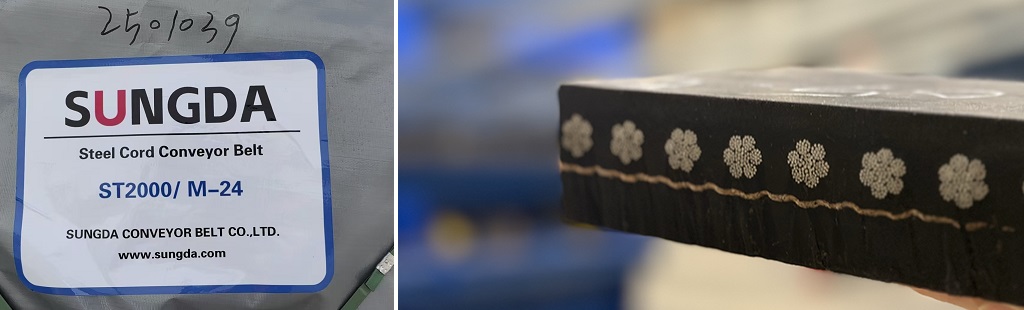

The steel cord conveyor belt consists of steel cord (ST800/ST1000/ST1250/ST1400/ST1600/ST1800/ST2000/ST2250 etc.) and rubber covering,the production process includes steps such as steel cord weaving, rubber mixing, extrusion and vulcanization. Compared with EP conveyor belts, steel cord conveyor belts have higher tensile strength, abrasion resistance and corrosion resistance, more importantly, due to the super tensile strength of steel cords, they overcome the problems of easy deformation and overstretching of EP conveyor belts, so it is more suitable for long-distance, heavy-duty and high-speed transportation, widely used in mining industry, steel mill, seaports, building materials, metallurgy and other industries, especially in harsh environments and high-intensity working conditions.

Characteristics:

1. High tensile strength: The belts are suitable for large span, long-distance transportation of materials.

2. Small elongation in use: The belts need only a very short take-up stroke distance.

3. The small diameter of drive pulley: The belt body has a layer of longitudinally arranged steel cords as its skeleton, and thus is resistant to flex fatigue. Therefore, a drive pulley of smaller diameter can be used to make the equipment smaller.

4. High adhesion between rubber and steel cord: The steel cords are coated with zinc on their surface, and also the rubber used has the property of good adhesion with steel cords. Therefore, the rubber is tightly adhered to the steel cords and is resistant to shock and difficult to drop, so the rubber belts are long in life.

5. Even tension of steel cords: Because of advanced techniques in manufacturing, the steel cords are very evenly arranged and have the same tension, so the belts are well-balanced in running and difficult to run awry.

6. Good trough ability: As the belt body has no transverse skeleton, it is easy to form a deep trough, so the belts can load more materials and prevent the materials from escaping.

7. Inspection of the belt with X-rays: Users can use X-rays to inspect damages of the skeleton steel cords on the conveyor machines to prevent accidents from happening.

Production parameter

| Item | ST630 | ST800 | ST1000 | ST1250 | ST1600 | ST2000 |

| Longitudinal Tensile strength (N/mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 |

| Steel cord diameter(mm) | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 6.0 |

| Space between cord(mm) | 10 ±1.5 | 10 ±1.5 | 12 ±1.5 | 12 ±1.5 | 12 ±1.5 | 12 ±1.5 |

| Top cover (mm) | 5 | 7 | 7 | 7 | 8 | 8 |

| Bottom cover (mm) | 4 | 4 | 5 | 5 | 6 | 6 |

| Item | ST2500 | ST3150 | ST3500 | ST4000 | ST4500 | ST5000 |

| Longitudinal Tensile strength (N/mm) | 2500 | 3150 | 3500 | 4000 | 4500 | 5000 |

| Steel cord diameter(mm) | 7.2 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 |

| Space between cord(mm) | 15 ±1.5 | 15 ±1.5 | 15 ±1.5 | 15±1.5 | 16 ±1.5 | 17 ±1.5 |

| Top cover (mm) | 8 | 8 | 8.5 | 8.5 | 9 | 9 |

| Bottom cover (mm) | 6 | 6 | 6.5 | 6.5 | 7 | 7 |

| Coating rank | Code | Stretch intensity MPa | Intensity to rupture MPa | Abrasion rate mm3 | After 70°C*7days aging, the changing rate for stretch intensity |

| Anti-split | H | >25.0 | >450 | 120< | -25~+25 |

| Common | D | >18.0 | >400 | 90< | -25~+25 |

| Anti-abrasion | L | >20.0 | >400 | 150< | -25~+25 |

Tags: DIN-Y,DIN-Z,DIN22102,Rubber conveyor belt,Steel cord conveyor belt