Steel cord conveyor longitudinal tear repair technology

Steel cord conveyor belt is generally used for the main lifting point of the conveyor, which is characterized by high speed and large lifting capacity. Most longitudinal tearing accidents of steel cord conveyor belts are caused by sharp-edged iron or large pieces of waste rock loaded on the conveyor belt. These stones are easily caught by the machine at the transfer point during transportation and cause longitudinal tearing of the steel cord conveyor belt. In general, when the steel cord conveyor belt tears the cord longitudinally, the measures taken are to cut the torn part, then replace the new conveyor belt with the corresponding length, and then connect the new conveyor belt to the old conveyor belt by using the hot vulcanization technology connection. It takes at least 20 hours to cure the head. Using cold bonding will greatly save time. SUNGDA talked about the repair process of the longitudinal tear of the steel cord conveyor belt of a certain mine for your reference:

The width of this conveyor is 1.6m and the running speed is 4m / s. The longitudinal tear was caused by sharp iron on the transport line. The tear of the first 42.5 meters of 43 meters is that the iron penetrates the belt along the wire in the conveyor belt. The longitudinal tear point lies at the end of the tear, causing a 15cm wide and 50cm long oblique opening and causing Two strands of wire broke. As a long-distance, large-volume steel rope conveyor belt, if the commonly used repairing piece is used for repair work, the use effect cannot be guaranteed. You can use the following methods to repair.

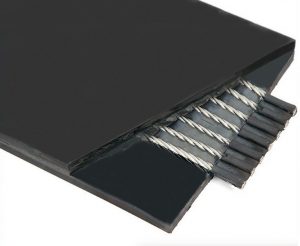

(1) Use a wallpaper knife to cut a triangular groove along the cord along the longitudinal tear of the steel cord conveyor belt. as the picture shows.

(2) Grind, clear, and mix the adhesive once;

(3) Put the mixed belt into the glue gun and heat it, so that the mixed belt is integrated into a viscous liquid;

(4) Apply the mixture for the second time;

(5) Apply and fill with a glue gun (Note: The application and fill must be uniform, slightly higher than the plane of the belt);

(6) After the mixed glue has cooled and solidified, level it with a planer to complete the repair work.

Treatment of oblique broken cord:

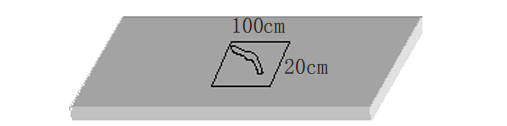

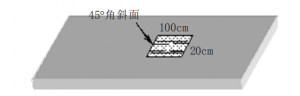

(1) With the broken cord as the center, make a mark with a length of 100 cm and a width of 20 cm, and make a 45 ° leading angle cut as shown in the figure.

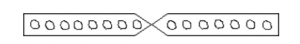

Cutting schematic

(2) Cut off the rubber compound in the middle.

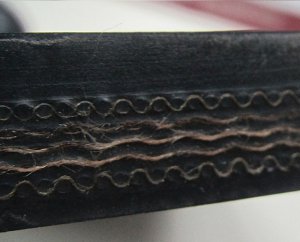

(3) Carry out the above repair work with reinforced repair strips on the lower part of the conveyor belt, and use it as a rubber-filled backing as shown in the figure.

Underlay schematic

(4) Add a clean (non-greasy) steel cord to each broken cord (same type as the steel cord in the steel cord belt).

(5) Perform repair work with a glue gun as described above.

(6) After the mixed rubber material has cooled and solidified, it can be cut flat with a flat knife to complete the entire job.

(7) It takes only six hours to complete the entire belt repair work.

Note: When working underground, it is necessary to use repair materials marked with the flame safety quality of the coal safety mark.

Tags: Steel cord conveyor belt