Quality supervision of steel cord conveyor belt

Steel cords as such are susceptible to corrosion. Belts with stainless steel cords were used in some very acidic environments underground but were never able to achieve a real breakthrough due to their high price and low specific strength.

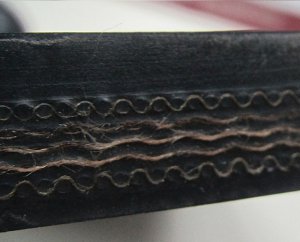

In the early days, water often got into a cord when the conveyor belt was damaged, and then spread throughout the cord like in a drinking straw, unnoticed from the outside. In extreme cases, sometimes, invisible corrosion pockets grew several hundred meters away from the damage. This was even more likely to occur at the open cord ends in the splice. In addition, the splice ramps were often torn open by scrapers which made it easier for dirt and water to penetrate the belt, resulting in delamination and rust in the splice.

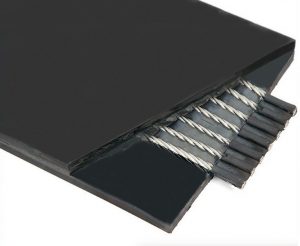

Nowadays, corrosion is no longer a problem on top-class steel cord conveyor belts, even with exterior damage, thanks to the use of high-quality, hot-galvanized cords of a special open design, combined with highly flowable and adhesive special rubber compound and state-of-the-art production technology.

These high-quality materials and modern processes as well as additional protection provided by cascaded ramps and synthetic transverse cord reinforcement, present numerous advantages for the splices, making corrosion unlikely here as well.

Nevertheless, there will always be incidents that trigger conveyor belt failures. Unplanned conveyor downtimes are often a catastrophic and very costly result, that must be avoided. Hence, good belt scanning is highly advisable.

Tags: Steel cord conveyor belt