How to achieve the best vulcanization effect as EP conveyor belt splicing

EP conveyor splicings cannot be used without vulcanization. Therefore, EP conveyor splicings need to be vulcanized before being put into use. However, to achieve the best vulcanization effect, some conditions are needed, such as temperature, time, and pressure. Let ’s take a closer look. .

1. When the EP conveyor belt is vulcanized, the physical and mechanical properties are the best, but they are not completely consistent. Therefore, the selection of curing time is based on the main properties of the product. Generally, the tensile standard is used. Other properties such as abrasion resistance, tear resistance, and deformation resistance must also be considered.

2. The vulcanization speed increases with the increase of vulcanization temperature. Increasing the vulcanization temperature can shorten the vulcanization time. However, in a certain range of vulcanization temperature, the vulcanization temperature of the general conveyor belt is 130-170 degrees, and the vulcanization temperature of the high-temperature EP conveyor belt is 150 -190 degrees. It depends on the specific conveyor model. High temperatures can cause varying degrees of damage to the physical properties of EP conveyor belts and carcass fiber materials(EP layer). Because you have to choose the right temperature. In a certain temperature range, increasing the curing temperature is one of the effective methods to improve production efficiency.

3. The determination of vulcanization temperature and time also considers the use of raw materials. Generally speaking, the vulcanization speed of synthetic rubber is slower than that of natural rubber, so the vulcanization temperature is higher or longer than that of natural rubber.

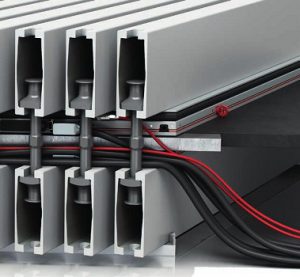

4.Vulcanization pressure but it is the fluidity of the rubber material, the rubber material is compact and easy to fill the mold, because the specifications are accurate, it is easy to penetrate into the internal EP carcass, increase the adhesion of the EP conveyor belt, and is also conducive to the rubber and rubber draw . It must be closely combined to prevent the conveyor belt from producing the so-called bubble phenomenon.

The above is an introduction to the process conditions of vulcanization of conveyor belts. It is worth noting that if the splicing has a long service life, you must choose a good conveyor vulcanizer when vulcanizing, and then choose a fresh rubber material , Rubber glue, so that the EP conveyor belt can reach the best vulcanization effect.

SUNGDA EP rubber conveyor belt series such as mining conveyor belt, heat resistant conveyor belt, and flame resistant conveyor belt adopt Continental conveyor belt technology, are developed to assure you of the high-quality rubber conveyor belt.

The combination of polyester in warp and nylon infilling provides technical low-stretch, high impact abuse resistance. Recommended for transporting abrasive materials, such as mining, rock, stone, ore, glass, granite, etc, for more information, please log on our website: https://www.sungda.com or email us by overseas.sungda@gmail.com

Tags: conveyor belt splicing