How to quickly repair the damaged rubber conveyor belt?

Rubber conveyor belts are the most common material conveying equipment in industrial production and are widely used in various processes of material conveying. During the use of conveyor belts, the most common problems are: foreign body scra...

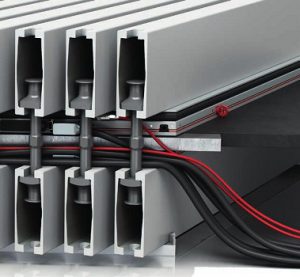

Various connection methods of flame resistant conveyor belt

The connection method of flame-resistant conveyor belt can be divided into mechanical spclicing and adhesive spclicing. According to the bonding temperature of the spclicing, there are two types of bonding splicing: thermal bonding and cold bonding. ...

How to achieve the best vulcanization effect as EP conveyor belt splicing

EP conveyor splicings cannot be used without vulcanization. Therefore, EP conveyor splicings need to be vulcanized before being put into use. However, to achieve the best vulcanization effect, some conditions are needed, such as temperature, time, an...

Rubber conveyor belt Cold Splicing vs Hot Vulcanizing Splicing-SUNGDA Conveyor Belt

In today’s splicing work for rubber conveyor belts, it seems that more and more belts are being transformed into thermal vulcanization. Engineers / end users claim that hot vulcanization belts are far superior to cold vulcanization belts, but ...

How many kinds of conveyor belt splicing methods?

All conveyor belts must be connected in an endless shape to be used, so the quality of the conveyor belt joints directly affects the service life of the conveyor belt and whether the conveyor line can run smoothly and smoothly. Common methods for con...

Can the core rubber of different manufacturers be mixed?

It is not recommended to mix skim rubber from different manufacturers because the formulations of skim rubber from different manufacturers are different. There are many kinds of compounding agents in rubber, and some will have an interactive reaction...