Are you in a right way at the steel cord conveyor belt repairing material?

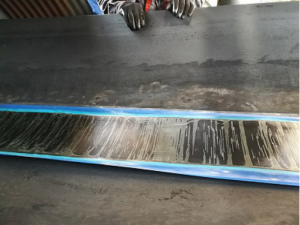

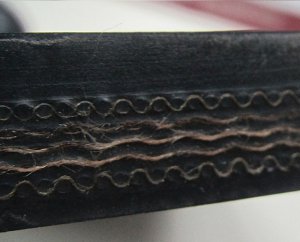

The steel cord conveyor belt has large tension and strong tensile strength. It should be repaired in time after damage. Otherwise, the steel cord conveyor belt may be broken, resulting in a waste of resources and reduced production efficiency. At present, the steel cord conveyor belt is mostly repaired by the cold vulcanization method after the damage occurs. During the repair process, special attention should be paid to the adhesion of the glue and the cooperation of the glue and the repair strip. The conveyor belt manufacturer will take a detailed understanding of it.

When the cold vulcanization repair method is used to repair the conveyor belt, the selection of the repair material is crucial, and the steel cord conveyor belt is required to repair the material when the cold vulcanization method is used for repairing.

1. Glue needs to have higher adhesion

The adhesive strength of ordinary glue is generally insufficient to meet the bonding requirements, and debonding, cracking, etc. usually occur after bonding.

The curing speed of cold vulcanized glue is more than 3 times that of ordinary glue. After curing, the bonding force is 10000 cps, which is the same level as that of hot vulcanized glue. It can fully meet the tension requirements after the wire belt is turned on.

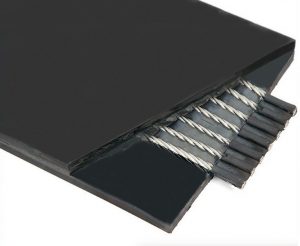

2. The repair strip reaches the maximum match with the glue

As a repair strip that acts as a bond at the tearing portion of the conveyor belt, an optimum fit to the cold vulcanized glue is achieved. If the repair strips are used, there are two types that are commonly used on the market, namely, ordinary repair strips and repair strips with CN semi-vulcanized layers. Among them, the advantages of the CN layer repair strip are more obvious.

The CN layer repair strip can generate a self-vulcanization cross-linking reaction between the cold vulcanized glue and the cold vulcanized glue, and the two melt and fuse on the surface of the conveyor belt, and the shear strength can reach 16N/mm2, which can effectively ensure The bonding effect after the steel ribbon is repaired.

The above are two points that should be paid special attention to during the repair process of the steel cord conveyor belt. I hope to help you. Only the quality of the bonding glue is passed through and the bonding is firm, so as to ensure the use of the steel cord conveyor belt to reduce the chance of damage again and improve the working efficiency. For more information on steel cord conveyors, please pay attention to our website www.sungda.com to continue to understand.

Tags: Steel cord conveyor belt