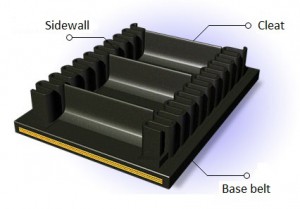

Sidewall Conveyor Belt

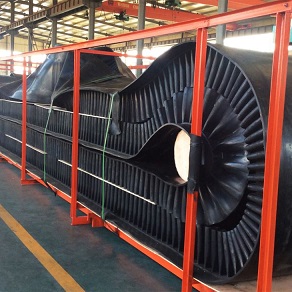

Corrugated sidewall conveyor belt is one of the most effective ways of elevating materials in a confined space,

the economy is achieved by single belt operation, wide range material can be handled, less space requirement,

no transfer point, low maintenance, and big capacity. A corrugated sidewall belt can be designed into a set of complete transportation system according to application.

Feature:

Increase the transporting capacity to 4 times compared to the standard conveyor belt.

Save installation space due to the possibility of increasing the angle of inclination up to 90。

Small pulley diameters may be used, without the need for skirt boards. Facility costs are reduced with flat rollers

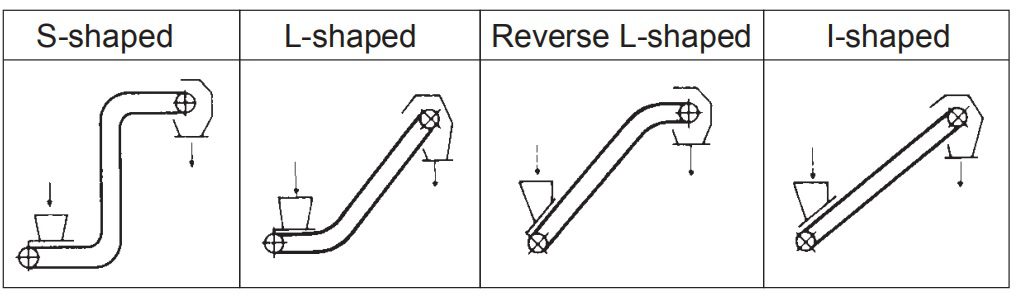

Sidewall major line shapes:

Base Belt Structure:

Reinforced core; Cross rigid.

Sidewall height: 60~500mm

Cleat height: 55~460mm

Belt core: Cotton, Nylon, EP or Steel Cord Belt width: 300~1800mm

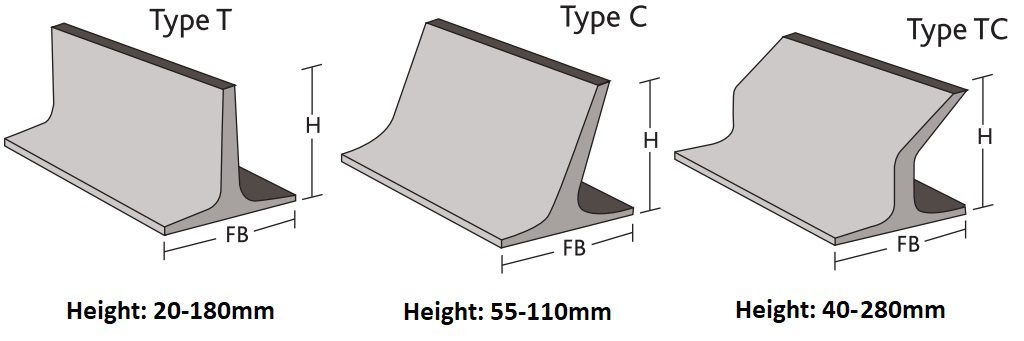

Cleat types:

The cleat is made of enforced fabric, solid, anti-shock to avoid distortion.

“T” cleat are normally used for abrasion condition

“C” cleat are normally used up to 40 degree

“TC” is normally used from 40 degrees to 90 degree

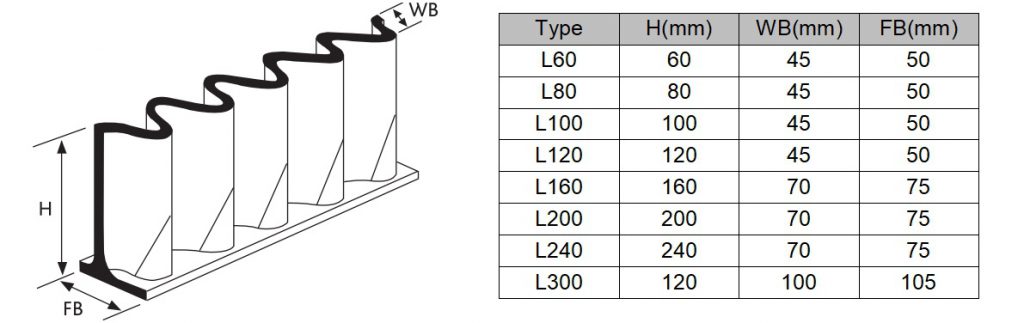

Sidewall type:

Please E-mail us to get the quick quotation in half-hour!

Tags: Corrugated sidewall conveyor belt,sidewall conveyor belt,vertical conveyor belt