Efficient Solid-Liquid Separation: The Working Principle and Maintenance of Vacuum Belt Filters

A vacuum belt filter is an industrial machine used in solid and liquid separation processes, especially the dewatering of sludge in the chemical industry, mining and water treatment. The filtration process is mainly obtained by passing a pair of filter cloths and belts through a roller system. The system takes sludge or mud as raw material and separates it into filtrate and solid filter cake.

The structure and working principle of the vacuum belt filter:

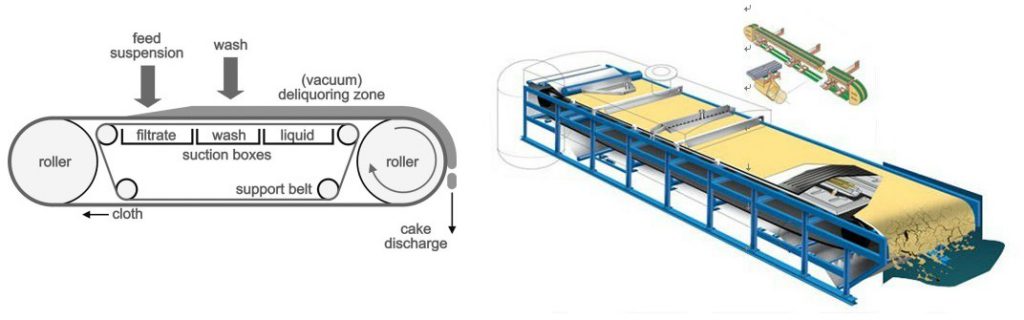

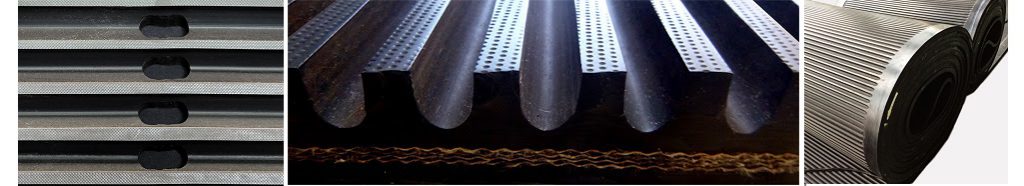

The structure of the vacuum belt filter consists of rubber filter belt, vacuum chamber, driving roller, conveyor belt support platform, feeding hopper, filter cloth misalignment adjustment device, driving device, filter cloth washing device, frame and other components. The vacuum belt filter makes full use of material gravity and vacuum suction to achieve solid-liquid separation.

The working principle of the vacuum belt filter: the circular filter belt is driven continuously by the motor through deceleration, and the filter cloth is laid on the conveyor belt to run synchronously. The filter belt is in sliding contact with the vacuum chamber (there is an annular friction belt between the vacuum chamber and the conveyor belt and water is passed into it to form a water seal). When the vacuum chamber is connected to the vacuum system, a vacuum suction area is formed on the filter conveyor belt; The filter is evenly distributed on the filter cloth. Under the action of vacuum, the filtrate passes through the filter cloth and collects through the transverse groove on the conveying filter belt, and enters the vacuum chamber through the small hole, and the solid particles are trapped and form a filter cake; the liquid entering the vacuum Discharged through the gas-water separator. As the rubber belt moves, the formed filter cake enters the filter cake washing area and the drying area in turn; the filter cloth is separated from the belt, and the filter cake is unloaded at the filter cake unloading roller; the filter cloth from which the filter cake is unloaded is cleaned and obtained ; Then re-enter the filter area after passing through a set of back-up rollers and correction devices

The filter belt is one of the most important components in the vacuum belt filter. Its performance will directly affect the operating efficiency of the filter. So when do you need to replace the filter belt under normal circumstances? We can according to the operation of the filter When the pressure value is used to judge whether the filter bag needs to be replaced. Normally, the filter belt reaches the critical value when the pressure difference is 0.5-1 kg/cm2. When we see the value on the pressure gauge reaches this value, it means that the filter belt needs to be replaced in time. In addition, when maintaining the filter, it is necessary to regularly check the condition of the filter belt, and replace it in time if any abnormality is found, otherwise the rupture of the filter belt will affect the entire treatment effect. In addition, correct operation and good maintenance can increase the service life of the filter belt.

The long-term load operation problem of the vacuum filter: the power system is the most prone to overload operation problems in the filter, because the power system not only provides power for the operation of the equipment components, but also provides a strong pressure for the filter plate, so that The filter plate becomes a closed filter environment. When the filter has been running for a long time, the hydraulic oil in the hydraulic system may overheat, causing the hydraulic oil to be unable to withstand strong pressure, and at the same time, the hydraulic system cannot generate enough power. In addition, when the pressure generated in the filter is insufficient, the pressure of the filter plate will also decrease, and the filter chamber in the equipment will leak, resulting in a decrease in work efficiency.

Tags: dewatering,sludge,vaccum horizontal filter belt,water treatment