Steel Cord Conveyor Belt

The steel cord conveyor belt consists of a multi-layer steel cord core(ST630/ST800/ST1000/ST1250/ST1600 etc.) and rubber covering,the production process includes steps such as steel cord weaving, rubber mixing, extrusion and vulcanization. Compared with EP conveyor belts, steel cord conveyor belts have higher tensile strength, abrasion resistance and corrosion resistance, more importantly, due to the super tensile strength of steel cords, they overcome the problems of easy deformation and overstretching of EP conveyor belts, so it is more suitable for long-distance, heavy-duty and high-speed transportation, widely used in mining industry, steel mill, seaports, building materials, metallurgy and other industries, especially in harsh environments and high-intensity working conditions.

Characteristics:

1. High tensile strength: The belts are suitable for large span, long-distance transportation of materials.

2. Small elongation in use: The belts need only a very short take-up stroke distance.

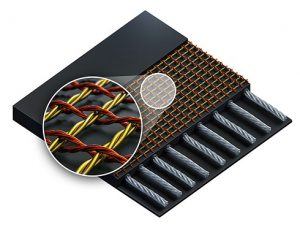

3. The small diameter of drive pulley: The belt body has a layer of longitudinally arranged steel cords as its skeleton, and thus is resistant to flex fatigue. Therefore, a drive pulley of smaller diameter can be used to make the equipment smaller.

4. High adhesion between rubber and steel cord: The steel cords are coated with zinc on their surface, and also the rubber used has the property of good adhesion with steel cords. Therefore, the rubber is tightly adhered to the steel cords and is resistant to shock and difficult to drop, so the rubber belts are long in life.

5. Even tension of steel cords: Because of advanced techniques in manufacturing, the steel cords are very evenly arranged and have the same tension, so the belts are well-balanced in running and difficult to run awry.

6. Good trough ability: As the belt body has no transverse skeleton, it is easy to form a deep trough, so the belts can load more materials and prevent the materials from escaping.

7. Inspection of the belt with X-rays: Users can use X-rays to inspect damages of the skeleton steel cords on the conveyor machines to prevent accidents from happening.

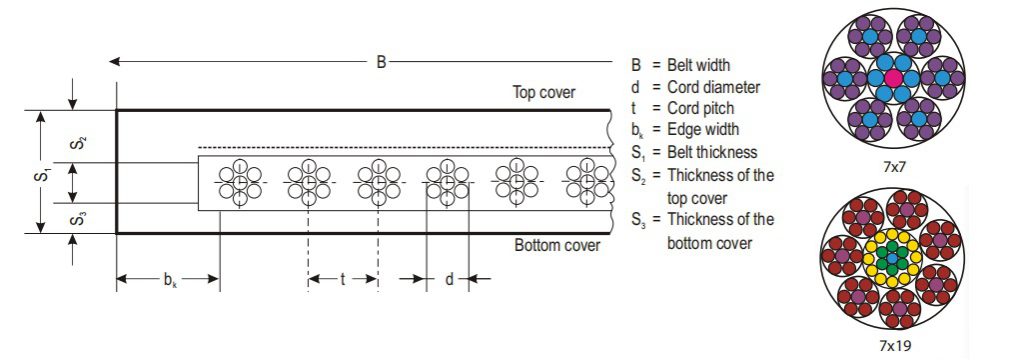

Steel Cord Conveyor Belt Carcass:

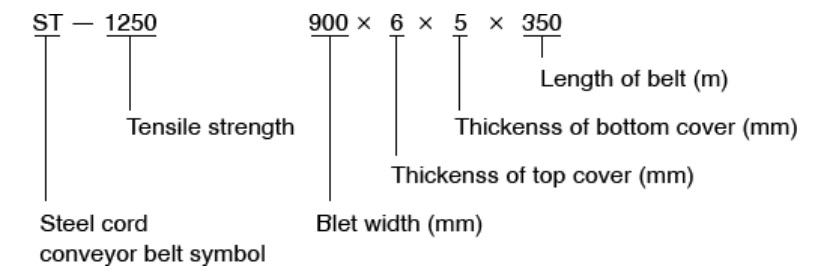

Steel cord conveyor belt’s key to symbol:

Steel cord conveyor belt specification:

Strength grade | Tensile strength (N/mm) | Steel Cord pitch (mm) | Steel Cord diameter (mm) | Min.breaking force (KN) | Min.cover thickness (mm) |

ST-500 | 500 | 10 | 2.5 | 5.5 | 4 |

ST-630 | 630 | 10 | 2.8 | 7 | 4 |

ST-800 | 800 | 10 | 3 | 8.9 | 4 |

ST-1000 | 1000 | 12 | 3.4 | 12.9 | 4 |

ST-1250 | 1250 | 12 | 3.8 | 16.1 | 4 |

ST-1400 | 1400 | 12 | 4.3 | 18 | 4 |

ST-1600 | 1600 | 12 | 4.7 | 20.6 | 4 |

ST-2000 | 2000 | 12 | 5.0 | 25.6 | 4 |

ST-2250 | 2250 | 12 | 6.6 | 29 | 4 |

ST-2500 | 2500 | 15 | 6.8 | 40 | 5 |

ST-2800 | 2800 | 15 | 7 | 44.8 | 5 |

ST-3150 | 3150 | 15 | 7.3 | 50.5 | 5.5 |

ST-3500 | 3500 | 15 | 8.2 | 56 | 6 |

ST-4000 | 4000 | 15 | 8.8 | 63.5 | 6.5 |

ST-4500 | 4500 | 16 | 9.7 | 76.3 | 7 |

ST-5000 | 5000 | 17 | 10.9 | 91 | 7.5 |

ST-5400 | 5400 | 17 | 11.3 | 98.2 | 8 |

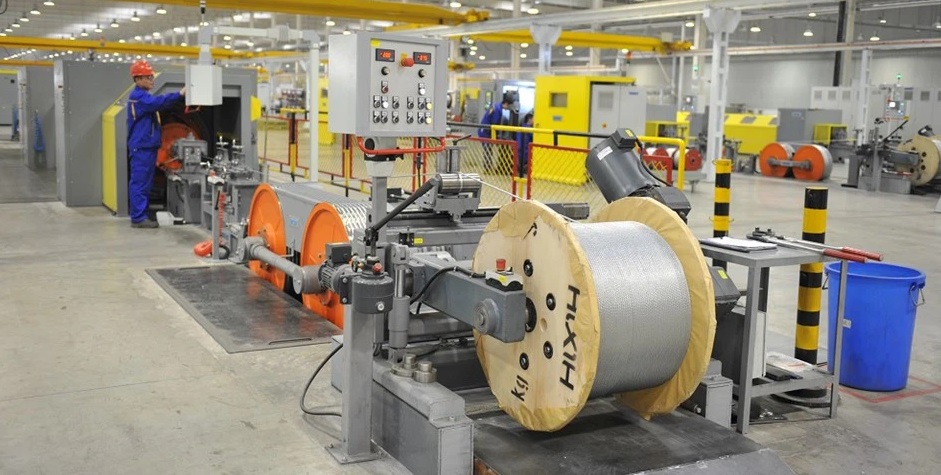

Steel cord is the core component of steel cord conveyor belts, providing the strength and stability necessary to withstand high tension and repeated pulling forces. SUNGDA’s steel cord utilizes Contitech’s specialized “HIXIH” brand high-strength steel cord, enabling SUNGDA’s series of steel cord conveyor belts to meet the demands of long-distance, high-strength, and various adverse operating conditions. The steel cord has the following advantages:

1.Zinc Galvanized and High Tension Open Type Steel Cord

Sungda selects its cord construction to provide the best specifications for particular applications. The cords are constructed to offer high flexibility, low elongation, and efficient, high-strength splice designs. The galvanized zinc coating serves as a bonding agent between the steel cord and skim rubber, providing a crucial barrier against corrosion.

2.Limited Take-up Travel

Sungda belts elongate a maximum of 0.25% at rated tension. This allows for lower-cost take-up systems on many applications, making Sungda the preferred choice for long overland and short stacker/reclaiming systems where minimum elongation is critical.

3.Long Splice Life:

Our proven splicing methods, validated by dynamic splice testers, result in dynamic splice efficiencies exceeding the 50% rating defined in DIN 22131 Part 3. With proper technique, splices on Sungda belts should last the life of the belt.

4.High Impact Resistance

Advanced cover compounds and skim rubber with superior adhesion combine to provide the impact, tear, and rip resistance demanded by your applications.

5.Lower Cost-per-Ton

Fewer conveyors and splices, shorter take-ups, and reduced belt inventory lead to longer belt life, longer splice life, and reduced downtime. All these factors contribute to a lower cost-per-ton of material conveyed, making a significant improvement in your bottom line.

Steel Cord Conveyor Belt Specification(PIW):

| Type | Minimum UItimate Tension (PIW) | Operating Tension (PIW) | Cable Diameter (in) | Cable Pitch (in) | Belt Modulus (PIW) |

| ST800 | 4568 | 685 | 0.142 | 0.688 | 329000 |

| ST1000 | 5710 | 856 | 0.142 | 0.547 | 411000 |

| ST1250 | 7138 | 1070 | 0.205 | 0.855 | 514000 |

| ST1600 | 9136 | 1370 | 0.205 | 0.666 | 657000 |

| ST2000 | 11420 | 1712 | 0.205 | 0.533 | 822000 |

| ST2500 | 14275 | 2140 | 0.205 | 0.450 | 1030000 |

| ST3150 | 17987 | 2697 | 0.315 | 0.768 | 1290000 |

| ST3500 | 19985 | 2996 | 0.315 | 0.690 | 1440000 |

| ST4000 | 22840 | 3424 | 0.362 | 0.792 | 1640000 |

| ST4500 | 25695 | 3852 | 0.394 | 0.805 | 1850000 |

| ST5000 | 28550 | 4280 | 0.433 | 1.098 | 2050000 |

| ST5400 | 30835 | 4623 | 0.433 | 1.023 | 2220000 |

Steel Cord Conveyor Belt’s Cover Grade:

| Rubber Cover Type | Characterization | Tensile Strength in Mpa(min) | Elongation at break %(min) | Abrasion in mm³ (max) | Hardness in SHA | Basic Material |

| DIN – X | Extreme abrasion resistance,superior resistance to cutting & tearing | 25 | 450 | 120 | 60±5 | NR/SBR |

| DIN – Y | Excellent Impact and abrasion resistance | 20 | 400 | 150 | 60±5 | NR/SBR |

| DIN – W | Good abrasion resistance,superior resistance to cutting & tearing | 18 | 400 | 90 | 60±5 | NR/SBR |

| DIN – Z | Normal abrasion resistance and cutting & tearing resistance | 15 | 350 | 250 | 60±5 | NR/SBR |

| DIN – K | Flame Retardant (M HSA) | 15 | 350 | 200 | 60±5 | CR |

| G | Oil Resistant | 15 | 400 | 200 | 60±5 | NBR |

| C | Chemical Resistant | 15 | 400 | 250 | 60±5 | CR/IIR |

| E | Anti-Static | 15 | 400 | 200 | 60±5 | NR/SBR |

| HR | Heat Resistant+100℃~+175℃ | 15 | 400 | 200 | 60±5 | SBR/EPDM |

| RMA – I | High abrasion resistance,superior resistance to cutting &tearing | 17 | 450 | 200 | 60±5 | NR/SBR |

| RMA – II | Resistant to cuts and gouges, flexible at lower temperatures | 14 | 400 | 250 | 60±5 | NR/SBR |

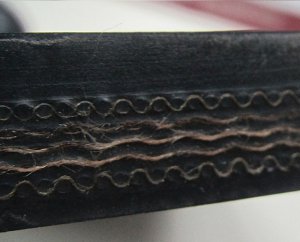

TRF(transverse reinforcing fabric) type

The feature of TRF type:

Prevention of longitudinal split or tear caused by hard materials or large objects with sharp edges.

Prevention of standing(jumping-out) of broken steel cords.

Less drop in pull-out force due to impact.

Compared with EP conveyor belts, steel cord conveyor belts are more complicated in the manufacturing process, which is mainly due to the following three reasons:

- Steel cord rope weaving: The core of the steel wire rope conveyor belt is made of multi-layer steel cord rope weaving, manufacturers are required to master professional weaving technology to ensure the tight connection and uniform distribution of steel wires.

- Rubber extrusion: The steel cord core needs to be covered by rubber, which requires rubber mixing and extrusion technology, manufacturers need to master the reasonable formula and extrusion process of rubber to ensure the uniformity and adhesion of the rubber covering layer.

- Forming and vulcanization of the conveyor belt:The forming process requires equipment that can combine the steel cord core with the rubber covering layer well to form a strong conveyor belt structure, the vulcanization process requires control of parameters such as temperature, pressure and time to ensure that the tape achieves the desired physical properties.

Since the manufacturing process of the steel cord conveyor belt is more complicated, the manufacturer is required to have very strong technical strength and a more advanced vulcanization production line, and have strict quality control processes before, during and after production, only advanced equipment and professional With a professional technical team, the manufacturer can ensure the production of high-quality wire rope conveyor belts to meet the needs of customers.

Sungda Steel Cord Conveyor Belt Workshop:

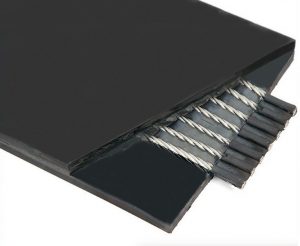

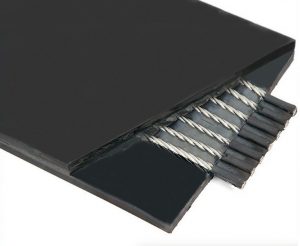

The ST1600 steel cord conveyor belt profile ready for package

Please E-mail us to get a quick quotation in half-hour!

Tags: Advantages and features of steel cord conveyor belts,applications of steel cord conveyor belts,Buying guide for steel cord conveyor belts,Common issues and troubleshooting for steel cord conveyor belts,Comparison of steel cord conveyor belts with textile conveyor belts,Customization options for steel cord conveyor belts,Industries that use steel cord conveyor belts,Innovations and advancements in steel cord conveyor belts,Installation and setup of steel cord conveyor belts,International standards and regulations for steel cord conveyor belts,Lifespan and durability of steel cord conveyor belts,Load capacity and weight-bearing capabilities of steel cord conveyor belts,long distance steel cord conveyor belt,Maintenance and care for steel cord conveyor belts,Manufacturers of steel cord conveyor belts,mining steel cord conveyor belt,PIW,Pricing and cost of steel cord conveyor belts,ST1000,ST1000 steel cord conveyor belt,ST1250 steel cord conveyor belt,ST1400,ST1600,ST1600 steel cord conveyor belt,ST2000 steel cord conveyor belt,ST2500 steel cord conveyor belt,ST3150 steel cord conveyor belt,ST630,ST630 steel cord conveyor belt,ST800,ST800 steel cord conveyor belt,Steel cord conveyor belt,Steel cord conveyor belt vs. other types of conveyor belts,steel mill,transverse reinforcing fabric,TRF,underground mining conveyor belt