Horizontal Vacuum Filter Belt

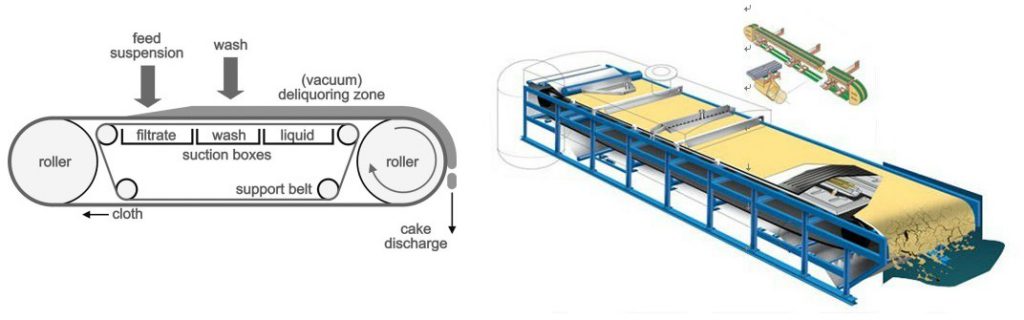

Rubber filter conveyor belts are also called vacuum rubber filter belts, filter belts, drainage belt. They are used on horizontal vacuum filter for dewatering work and cake washing. The width of the rubber filter belts we produce can reach 5500mm.

Rubber filter conveyor belts are divided into ordinary filter conveyor belts, heat-resistant rubber filter conveyor belts, oil-resistant rubber filter belts, acid and alkali-resistant filter belts and other types of rubber filter belt products.

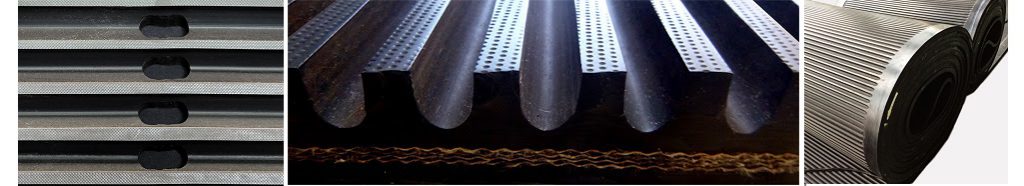

SUNGDA produces dewatering horizontal vacuum filter belt & drainage belts in specially designed molds which form the drainage grooves, lips, and center ribs. Molding the entire shape of the drainage belt allows us to tightly control belt straightness and dimension. In vacuum filtration, uniform product is obtained by precise construction. Our goal is uniform construction to ensure properly centered drainage holes which allow a consistent application of vacuum. The symmetric drainage channels on our belts result in a consistent hydraulic and pneumatic capacity and provide an unmatched amount of open area on a drainage belt top surface.

In addition, the heat and high temperature resistant horizontal vacuum filter conveyor belt is also an advantage over our peers. For filtering high temperature materials, 80 ℃ ~105 ℃. The cover rubber is made of EPDM rubber material with excellent heat resistance and aging resistance; the belt carcass is made of high-strength polyester fabric, and heat-resistant glass cloth can be laid between the cover rubber and the carcass layer; The effect of high temperature and filtrate on the framework material. So that our filter belt can adapt to work in high temperature environment, especially the filtration of large aluminum plants.

1. Acid and alkali resistant horizontal vacuum filter conveyor belt:

It is suitable for working environment in contact with acid and alkali, such as phosphate fertilizer manufacturing, alumina industry, catalyst (4A zeolite) and other industries. The covering rubber is blended with rubber and plastic and filled with inert materials with superior acid and alkali resistance, which is better than neoprene in acid and alkali resistance. The belt carcass material uses polyester fabric, which is more reliable than the surface fabric carcass in acid and alkali resistance. The drain hole is made of pure glue, which prevents the penetration of acid and alkali liquid through the cloth layer to layer the filter belt, which reduces the service life of the filter belt;

2. Heat-resistant horizontal vacuum filter conveyor belt:

Mainly used for filtering high temperature materials, 80℃<temperature<180℃. According to the main performance of heat-resistant belt damage and even loss of work ability. Different heat-resistant grades, use EPDM or styrene-butadiene rubber as the cover rubber, the belt carcass material is made of high-strength polyester fabric, the cover rubber and the horizontal vacuum filter belt carcass layer are laid with heat-resistant glass cloth, and the drain hole is made of heat-resistant pure The rubber layer prevents damage to the belt carcass caused by high temperature. Greatly increase the life of the heat-resistant filter belt;

3. Oil-resistant horizontal vacuum filter conveyor belt:

The covering rubber adopts nitrile rubber with high acrylonitrile content as the main material and polyester fabric as the horizontal vacuum filter belt carcass material. It is suitable for filtering, oily materials and environments in contact with various working oils. It has the advantages of low volume change rate, high strength retention, and wide application range;

4. Cold-resistant horizontal vacuum filter conveyor belt:

The horizontal vacuum filter belt’s carcass is made of polyester fabric, and the cover rubber is a combination of natural rubber and butadiene rubber, which has the characteristics of high elasticity, impact resistance and cold resistance. It can be used normally in an environment of minus 40°C.

Features and applications of horizontal vacuum filter belt: the product can achieve continuous filtration, washing, drying, filter cloth regeneration: high filtration rate, large production capacity, good washing effect, low cake moisture, flexible operation and other advantages.

Applied to solid-liquid separation in petroleum, chemical, pharmaceutical, dye, food, metallurgy, mineral processing, power industry and water separation treatment in industry and life, such as dehydration of phosphoric acid, potassium oxide, alumina, citric acid, and barium sulfate. Desulfurization of exhaust gas from power plants, etc.

Tags: 2600mm wide conveyor belt,2800mm wide conveyor belt,3000mm wide conveyor belt,3200mm wide conveyor belt,5000mm width belt,belt filter press,cake washing,dewatering filter belt,drainage belt,EP rubber conveyor belt,extra wide conveyor belt,horizontal vaccum filter belt,Rubber conveyor belt,super width conveyor belt,vaccum horizontal filter belt,vacuum belt filter