Pipe (Tubular)Conveyor Belt

General Introduction:

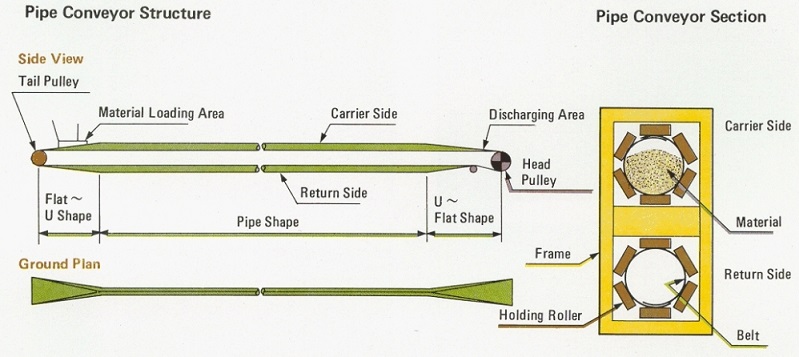

Pipe conveyor belt (also called tubular conveyor belt)is used to support the pipe belt conveyor, with the help of external force in the whole transportation line or part of the transportation line of the conveyor belt into a tubular shape. Pipe conveyor belt use the high tenacity EP fabric or steel cord as the core of carcass, using the high strength, high abrasion resistant rubber as top and bottom cover, the belt will change from plane to U shape on operation, and finally rolled into a tube for enclosed conveying.

Technical Characteristics:

1. Moderate rigidity for tubing and bend easily, with the ability to maintain stability of the roundness.Pipe conveyor belts can be bent horizontally, vertically or diagonally, making them suitable for complex layouts and limited-space environments. This makes it possible to implement more flexible transmission lines within limited space.

2. The sealing is good at the overlap edge, fatigue resistance, abrasion resistance, with stable bearing capacity.

3. As enclosed conveying, the materials won’t float in the sky or fall, and will not affect the environment, especially for the fine materials such as powder or paste.

4. To protect the material from wind, rain, snow and some other environment.

5. Compared with traditional flat conveyor belts, pipe conveyor belts consume less energy during transportation. This is because the tubular structure can reduce the resistance and friction of the material and reduce the energy required for transportation.

The width of belt and corresponding pipe diameter specifications (Unit: mm)

Nominal pipe dia.(mm) | Width (mm) | Size of overlap(mm) | Actual pipe dia.(mm) | Loading area at 70%(mm) | Capability at speed 2m/s(m3/h) | Lump size (Max.) |

100 | 430 | 115 | 100.27 | 0.005 | 40 | 40 |

150 | 600 | 129 | 143.24 | 0.011 | 81 | 80 |

200 | 780 | 122 | 186.21 | 0.019 | 137 | 100 |

250 | 900 | 215 | 279.18 | 0.028 | 208 | 130 |

300 | 1050 | 158 | 286.48 | 0.045 | 325 | 150 |

350 | 1300 | 201 | 343.77 | 0.064 | 468 | 180 |

400 | 1600 | 244 | 401.07 | 0.088 | 637 | 200 |

450 | 1650 | 237 | 458.37 | 0.115 | 832 | 220 |

500 | 1900 | 330 | 507.5 | 0.145 | 850 | 230 |

600 | 2250 | 366 | 609 | 0.205 | 1020 | 250 |

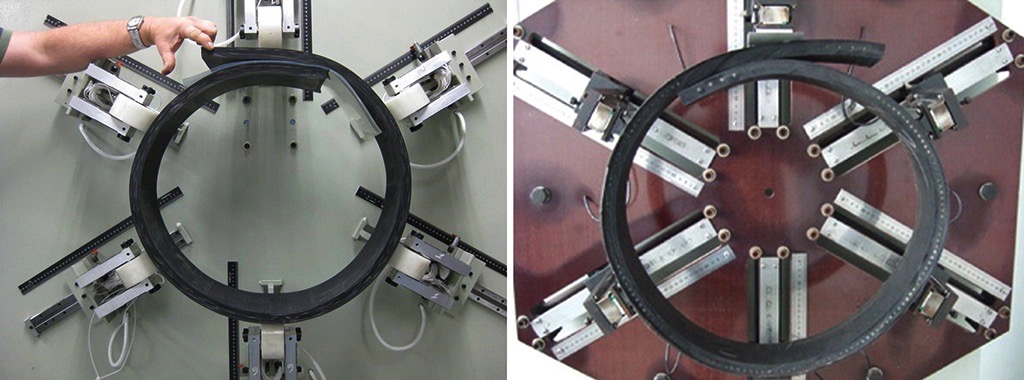

Due to the unique structure and applications of pipe conveyors, they require higher technical specifications compared to conventional conveyor belts. For example, the requirements for EP (ethylene propylene) and NN (nylon) fabrics include enhanced flexibility in the latitudinal direction, thicker skim rubber, and stronger adhesion between fabrics and cover. Consequently, the production of pipe conveyors imposes greater demands on conveyor belt manufacturers’ capabilities, necessitating them to possess stringent production management and quality testing capabilities.

Pipe Rubber Cover Grade:

| Cover Grade | Country | Applicable Standards | Min.Tensile Strength(Mpa) | Min.Elongation at Break(%) | Max.Abrasion Loss(mm3) |

| DIN-Z | Germany | DIN22102 | 15 | 350 | 250 |

| DIN-Y | Germany | DIN22102 | 20 | 400 | 150 |

| DIN-X | Germany | DIN22102 | 25 | 450 | 120 |

| DIN-W | Germany | DIN22102 | 18 | 400 | 90 |

| RMA-I | U.S.A | RMA | 17 | 400 | 150 |

| RMA-II | U.S.A | RMA | 14 | 400 | 200 |

| ARPM RMA-I | U.S.A | ARPM | 17 | 400 | 125 |

| ARPM RMA-II | U.S.A | ARPM | 14 | 400 | 175 |

| ISO-L | International | ISO -10247 | 15 | 350 | 200 |

| ISO-H | International | ISO -10247 | 24 | 450 | 120 |

| ISO-D | International | ISO -10247 | 18 | 400 | 100 |

| AS-N | Australian | AS -1332 | 17 | 400 | 200 |

| AS-M | Australian | AS -1332 | 24 | 450 | 125 |

| AS-A | Australian | AS -1332 | 17 | 400 | 70 |

| SANS-N | South Africa | SANS-1173 | 17 | 400 | 150 |

| SANS-M | South Africa | SANS-1173 | 25 | 450 | 120 |

| SANS-A | South Africa | SANS-1173 | 18 | 400 | 70 |

| BS-M | UK | BS-490 | 24 | 450 | 120 |

| BS-N | UK | BS-490 | 17 | 400 | 200 |

| IS-N-17 | India | IS 1891 | 17 | 400 | 200 |

| IS-M-24 | India | IS 1891 | 24 | 450 | 150 |

| JIS-G | Japan | JIS-K 6332 | 14 | 400 | 250 |

| JIS-L | Japan | JIS-K 6332 | 15 | 350 | 200 |

| JIS-D | Japan | JIS-K 6332 | 18 | 400 | 100 |

| JIS-H | Japan | JIS-K 6332 | 24 | 450 | 120 |

| GB-H | China | GB/T 7984 | 24 | 450 | 120 |

| GB-D | China | GB/T 7984 | 18 | 400 | 100 |

| GB-L | China | GB/T 7984 | 15 | 350 | 200 |

SUNGDA CONVEYOR BELT CO.,LTD.

Tags: EP conveyor belt,manufacture,pipe conveyor belt,steel cord,tubular,TUBULAR CONVEYOR BELT